Three-dimensional paper-based microfluidics and manufacture method thereof

A technology of microfluidic chip and manufacturing method, which is applied in the direction of analyzing materials and instruments, and can solve the problems of inability to carry out the analysis process, reduce the fluid flow rate, and pollute the test results, etc., and achieve the easy operation, easy acquisition, and simple manufacturing process of the manufacturing process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

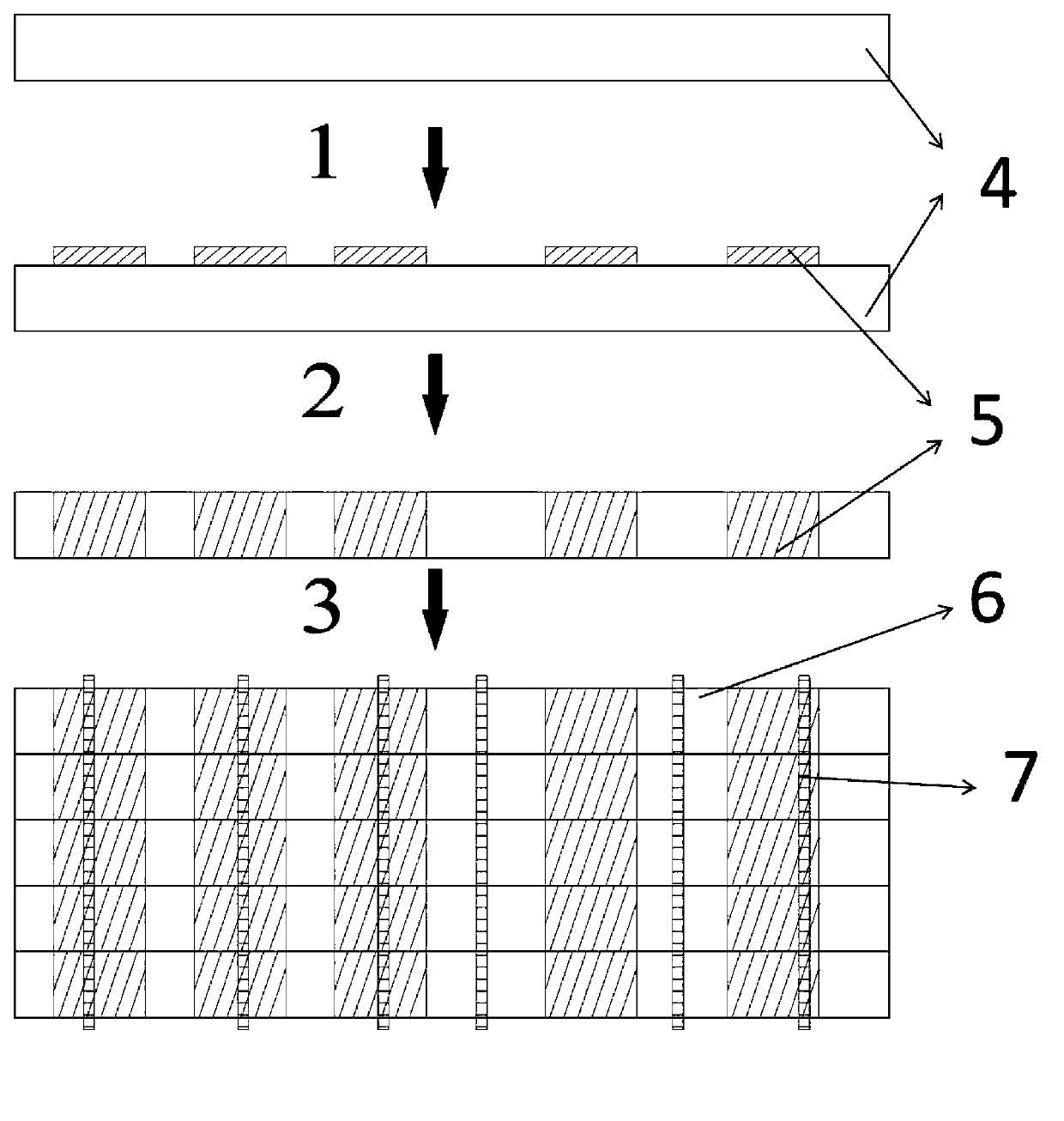

[0021] Example 1: Making a three-dimensional paper chip using the bookbinding method

[0022] Use drawing software to design the required chip design pattern on the computer, then print the chip design pattern on the filter paper with a wax spray printer, and then put the filter paper printed with wax on the surface into an oven at 150 degrees to bake for 3 minutes (this process The wax will melt and permeate the filter paper), forming a hydrophilic / hydrophobic interphase area, and then take it out to cool, and then get a two-dimensional paper microfluidic chip. Stack the six-layer two-dimensional paper microfluidic chip, and then use a stapler to staple the staples into the designed binding position of the chip to obtain a three-dimensional paper chip. The specific flow chart is as figure 1 Shown (includes three main steps: 1) wax spray printing; 2) cutting and baking; 3) lamination and binding. )

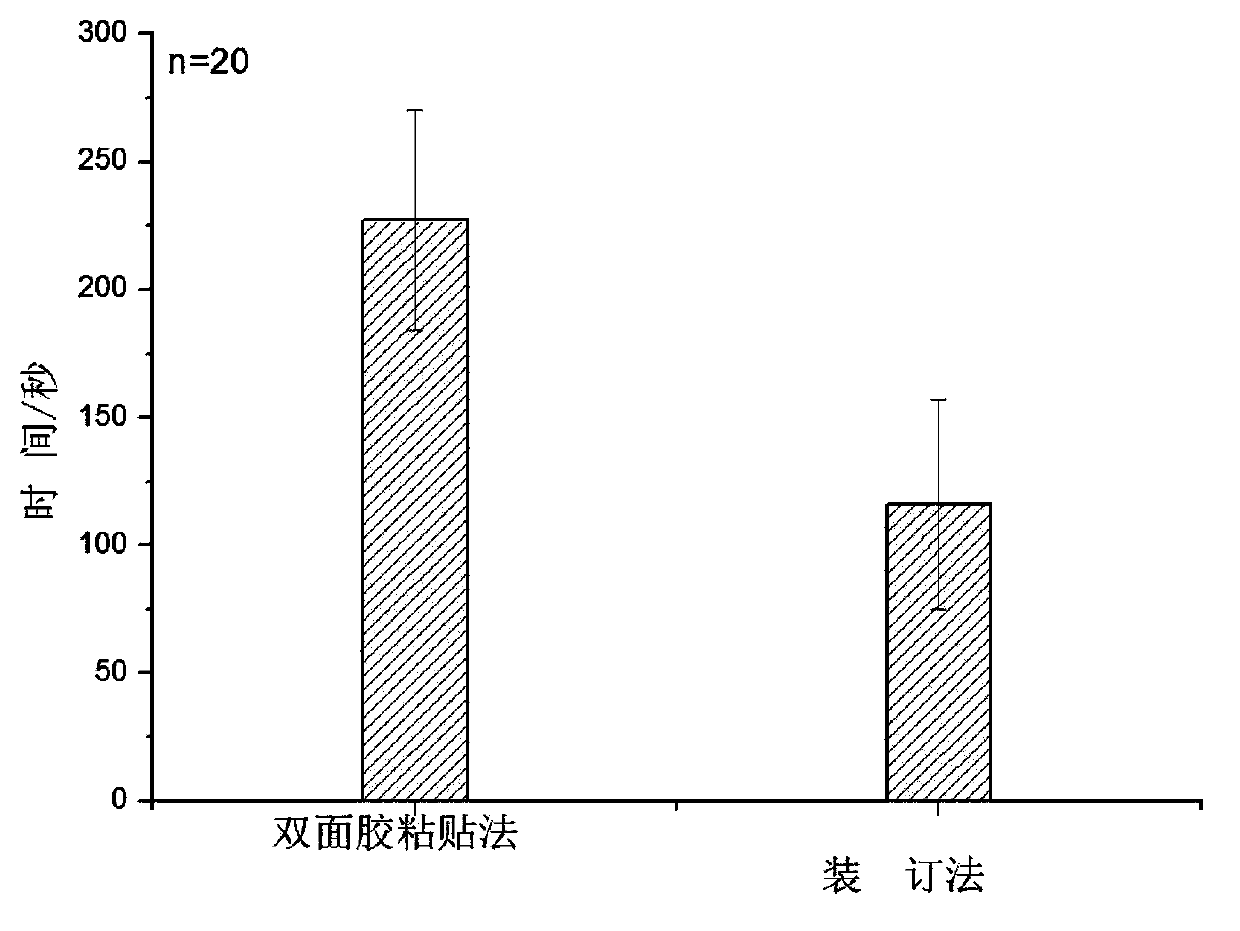

[0023] This fabrication method is simple, fast, and low-cost, which is ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com