Three-dimensional detection method for defects of sealing surface

A three-dimensional detection and sealing surface technology, applied in the field of defect detection, can solve the problems of affecting measurement accuracy, increasing the dose of radiation received by operators, and unable to quantify the size of defects, so as to improve measurement accuracy, eliminate missed inspections, and achieve size quantification. The effect of detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

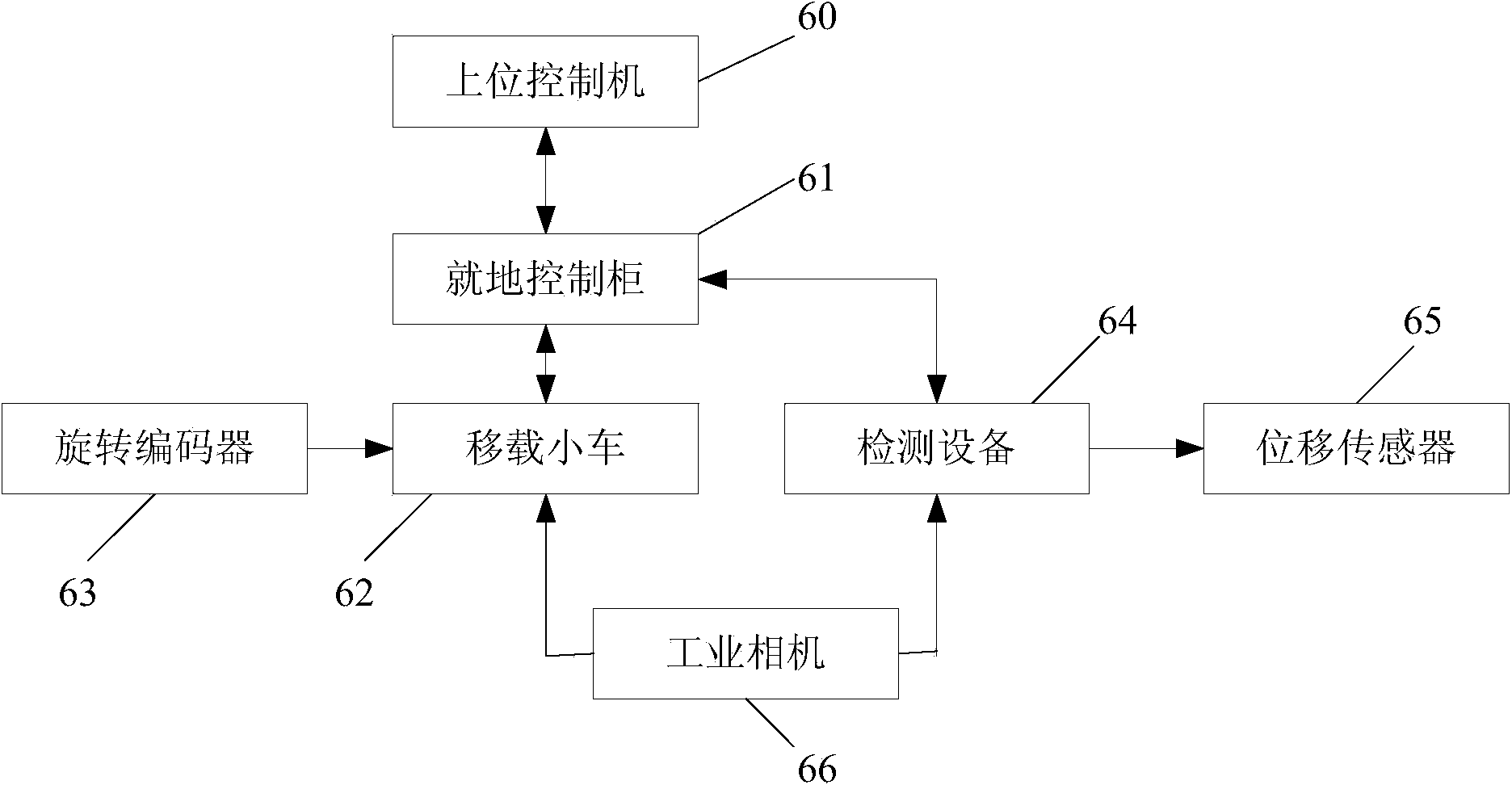

[0028] Embodiments of the present invention will now be described with reference to the drawings, in which like reference numerals represent like elements.

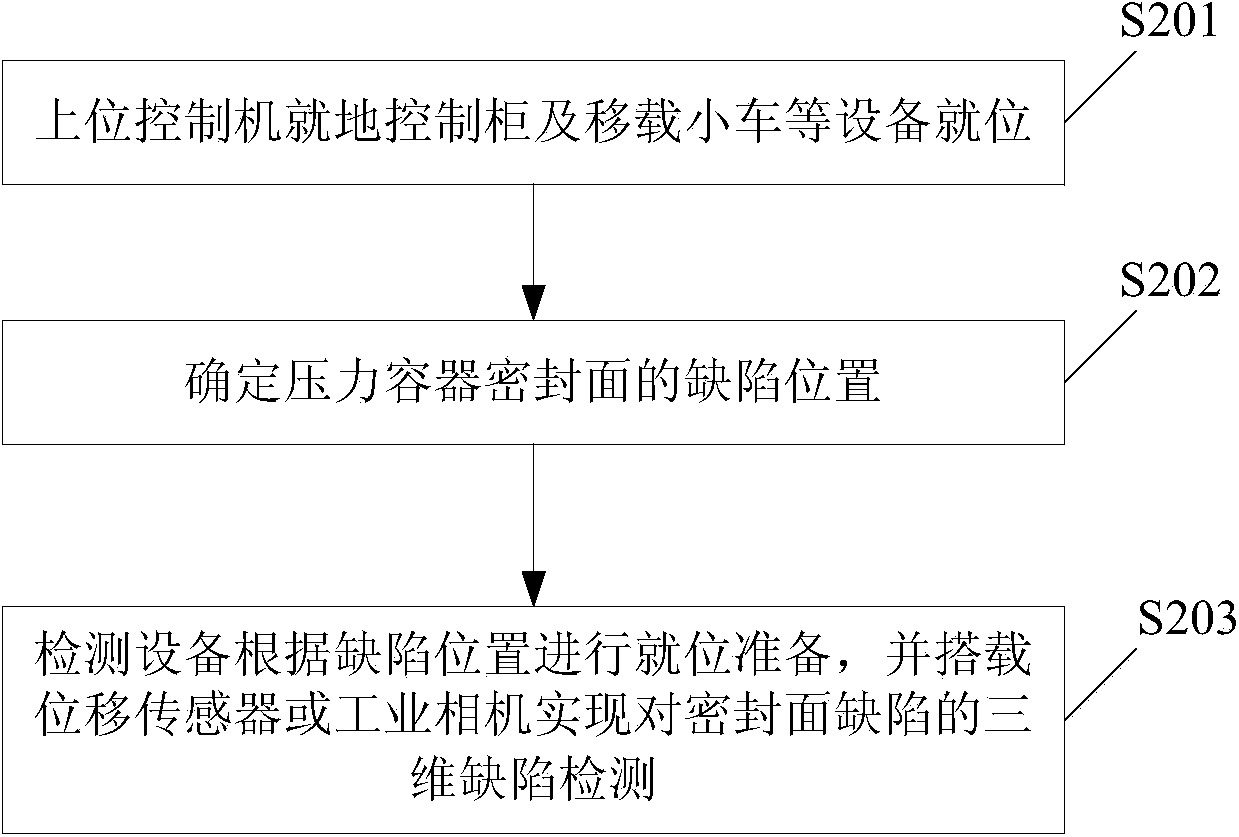

[0029] Please refer to figure 1 , the sealing surface three-dimensional defect detection method of the present invention comprises the following steps:

[0030] S101, acquiring a picture with scratches on the sealing surface;

[0031] S102, obtaining the length and initial width of the scratch according to the picture with the scratch;

[0032] S103. Determine the scanning path according to the initial width;

[0033] S104, planning a scanning trajectory according to the scanning path;

[0034] S105, scanning the scratches along the scanning track to determine the depth and final width of the scratches.

[0035] Compared with the prior art, the three-dimensional detection method for sealing surface defects of the present invention first obtains pictures of all scratches on the sealing surface, thereby basically elimin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com