Regenerative combustion device applicable to stable combustion of compounded tangent-flow and direct-flow gas with low calorific value

A combustion device and low calorific value technology, applied in the field of clean utilization of gas, can solve the problems that low calorific value gas is difficult to burn stably and continuously, reduce combustion efficiency and burnout rate, and easily form channel flow, etc. The effect of reducing nitrogen oxides and increasing the degree of fluid mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

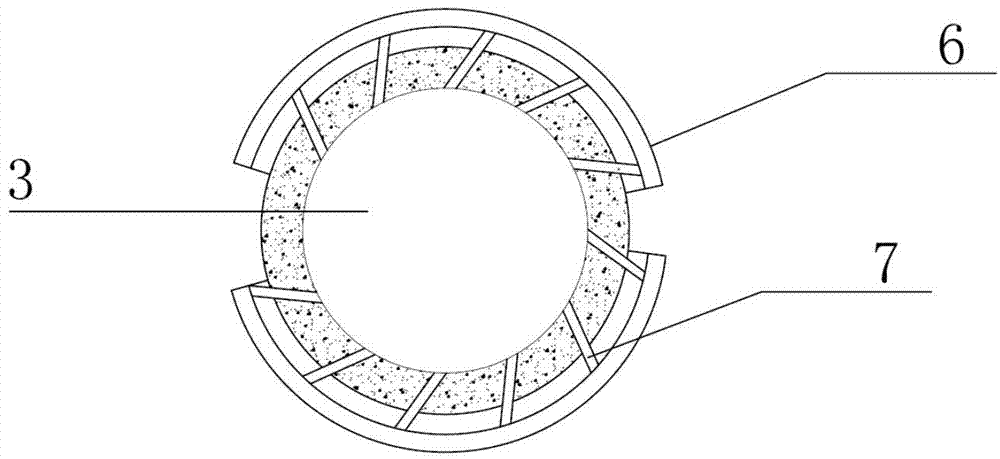

[0038] The present invention is suitable for low-calorific-value gas cut-flow and direct current compound stable combustion and thermal storage combustion device, which can realize cut-flow and direct-current composite air intake and stable combustion and heat storage, and is suitable for stable combustion of low calorific value gas, such as figure 1 As shown, you can choose to use the two-stage combustion stabilization cone design. In this combustion process, firstly, the entire combustion tower is preheated through the ignition hole 11. When the temperature in the combustion tower is higher than 900 ° C, the ignition is stopped, and one pass through the gas inlet At the same time, 55% of the air is supplied through the primary air pipe 9 through the air chamber 12 at the bottom of the combustion tower 3, and mixed with the gas for combustion, and the mixed gas passes through the first-stage combustion stabilizing cone 2 The initial heating and mixing are carried out during th...

Embodiment 2

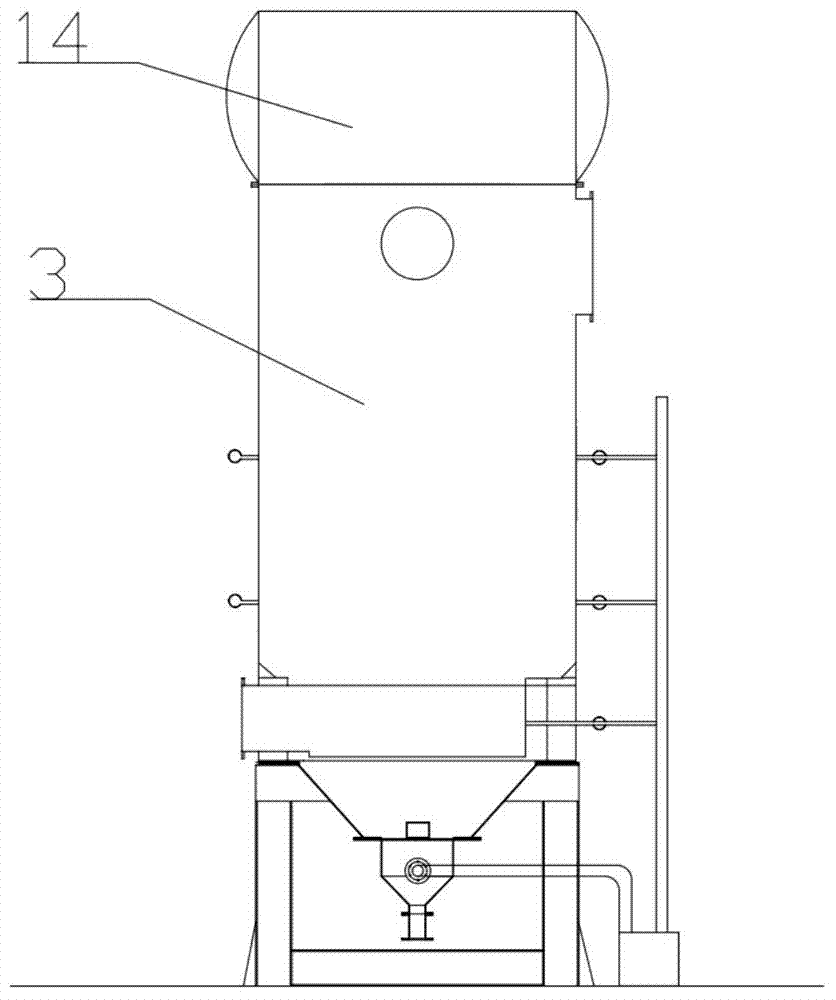

[0040] This embodiment is suitable for burning low calorific value gas while generating steam. The specific process flow is similar to the process described in embodiment 1, the difference is that this embodiment generates steam by installing a boiler 14 on the top of the combustion tower 3, and the steam is used for the factory's own use or power generation. Membrane walls or heat exchange tube bundles can be arranged inside the combustion tower 3, and the membrane walls or heat exchange tube bundles are connected to the boiler 14, and the internal temperature of the combustion tower can be adjusted by controlling the heat exchange.

Embodiment 3

[0042] This embodiment is suitable for burning low calorific value gas while generating steam. The specific process flow is similar to that described in embodiment 2, except that the combustion tower 3 is connected to the boiler 14 through pipes in this embodiment. The boiler form can be a hot water boiler or a low pressure steam boiler. This type of connection means that the boiler load can be flexibly changed according to the production demand, and will not affect the combustion process of low calorific value gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com