Tunnel ditch insulation structure

A ditch and tunnel technology, applied in drainage, safety devices, mining equipment, etc., can solve problems such as poor drainage, difficult construction, and disease formation, and achieve the effects of convenient replacement, investment saving, and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in combination with specific embodiments.

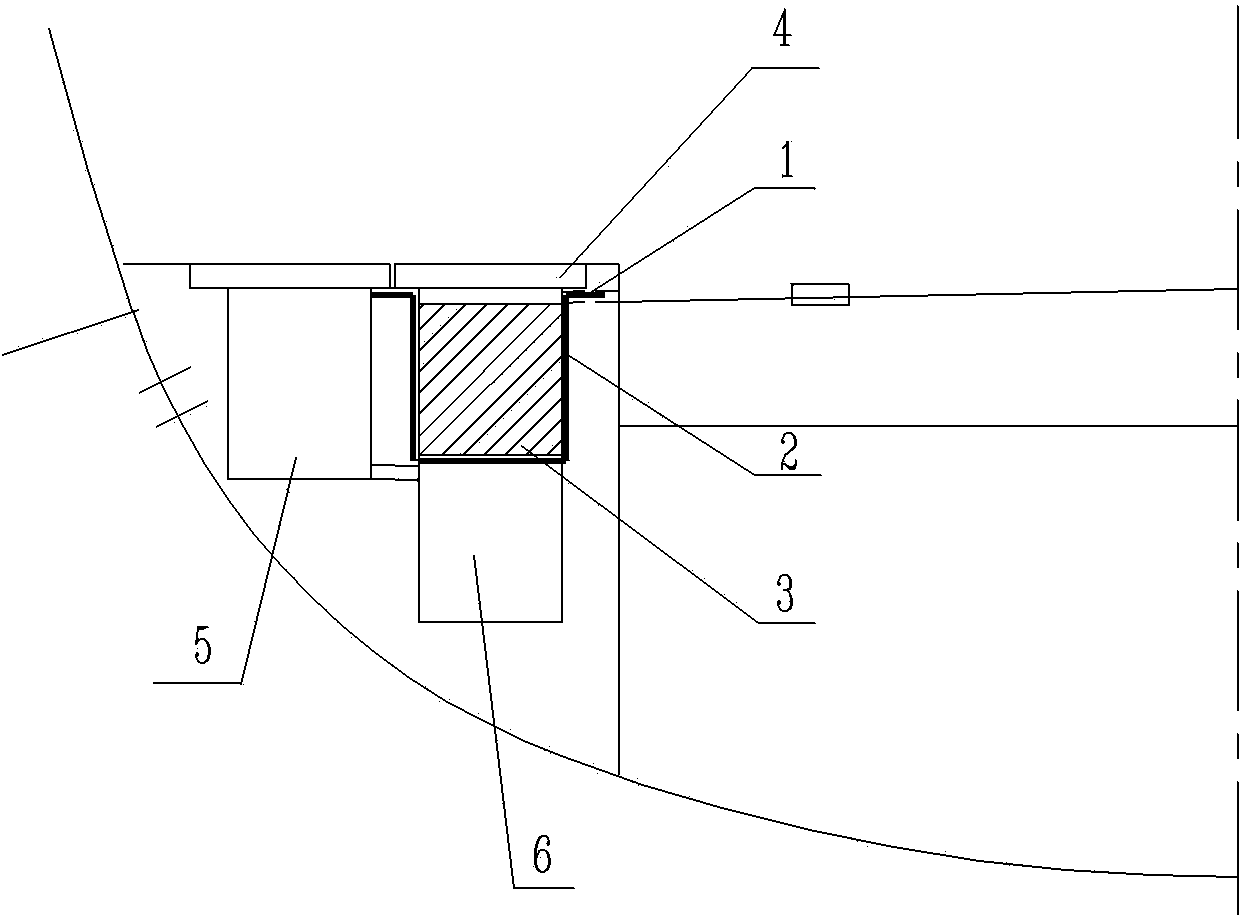

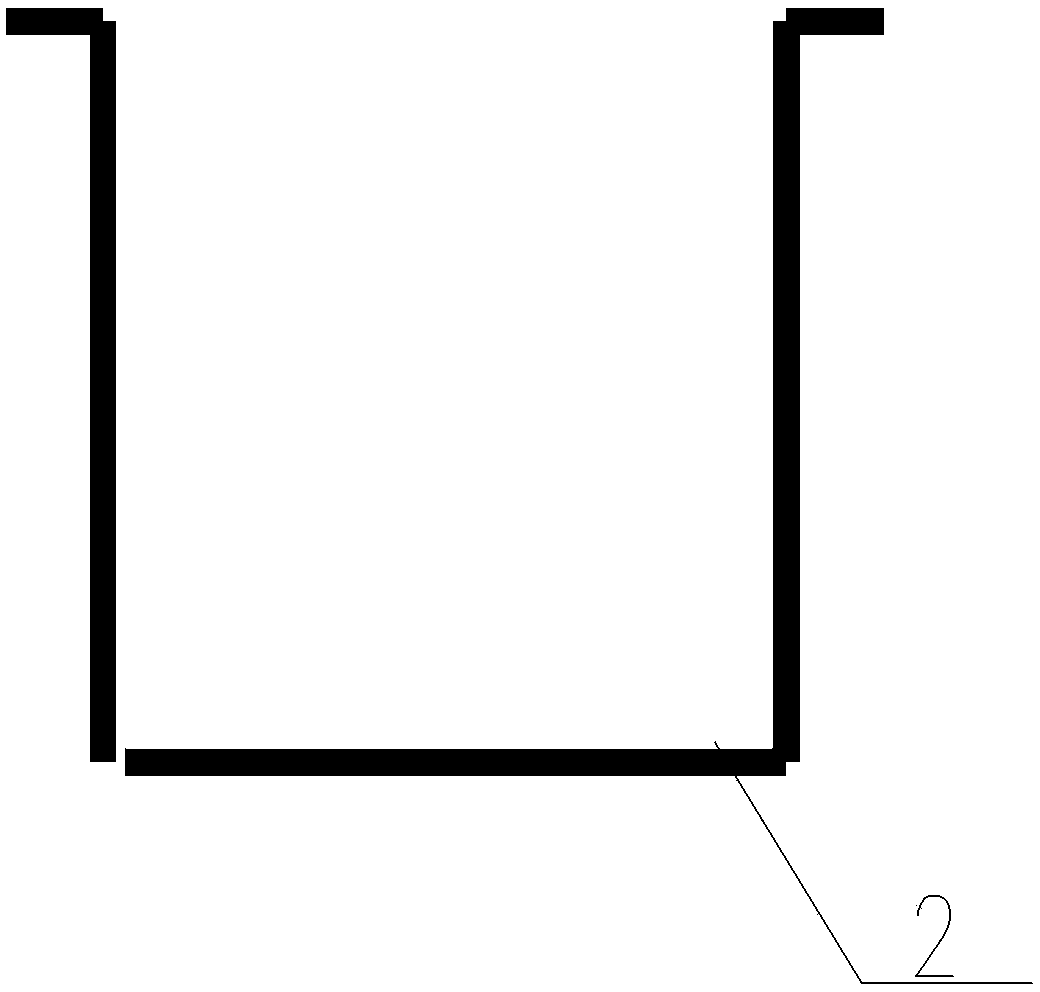

[0016] The present invention relates to a tunnel gutter insulation structure, which is arranged longitudinally along the gutter, and above the gutter 6 in the tunnel, a steel bar support 2 with a U-shaped cross section is arranged, and the bottom surface of the steel bar support 2 is higher than the height of the water surface in the gutter 6. The reinforcing bar bracket 2 is filled with thermal insulation material 3 . The top edge of the steel bar support 2 is bent to both lateral sides, placed in the groove 1 on the surface of the ditch wall provided on both sides of the top of the ditch 6, smoothed with cement mortar, and covered with a ditch cover plate 4 above to form a cold The setting form of the thermal insulation ditch of the tunnel in the district can achieve the effect of not affecting the thermal insulation on the basis of improving the difficulty of construct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com