A device and method for anchoring and supporting soil with vortex compression and expansion of fine stone concrete

A technology of fine stone concrete and vortex pressure, applied in mining equipment, earthwork drilling, excavation, etc., can solve the problems of high torque requirements of drilling rigs, difficult to meet requirements, poor anchorage reliability, etc., and achieve low cost, simple construction, and enhanced anchorage. force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

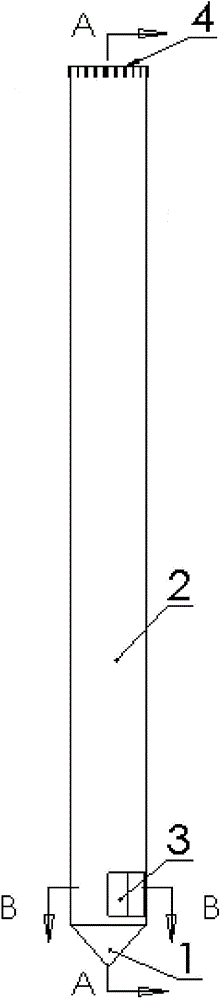

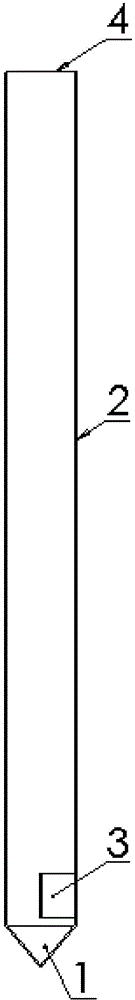

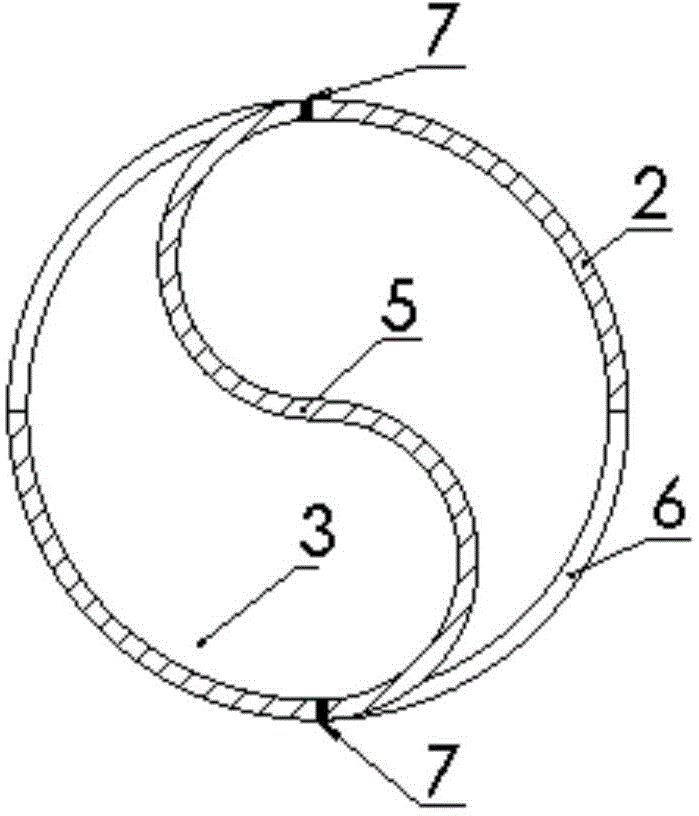

[0021] Such as figure 1 , figure 2 As shown, the equipment for anchoring and supporting soil with vortex extrusion and expansion of fine stone concrete includes: steel anchor pipe 2, rotating gear 4, vortex pressure blade 5; Installed inside the opening of the steel anchor pipe; where:

[0022] The steel anchor pipe 2 is a metal circular pipe, the lower part of which is a cone 1, and about 1 meter away from the bottom of the steel anchor pipe 2, a pair of outlets 6 of the vortex pressure chamber are opened symmetrically along the axial direction of the steel anchor pipe, as fine stone concrete extruded outwards. pressure outlet, the width of each opening (the length along the circumferential direction of the steel anchor pipe) is 1 / 4 of the circumference of the steel anchor pipe, and the opening height is the same as the height of the vortex pressure blade 5; the vortex pressure blade 5 consists of two identical The semi-circular steel plate is anti-symmetrically welded, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com