Soil dehydration desiccation or solidification method

A soil and drying technology, applied in soil protection, construction, infrastructure engineering, etc., to achieve the effect of increasing the mud content, reducing the moisture content, and reducing the storage yard

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

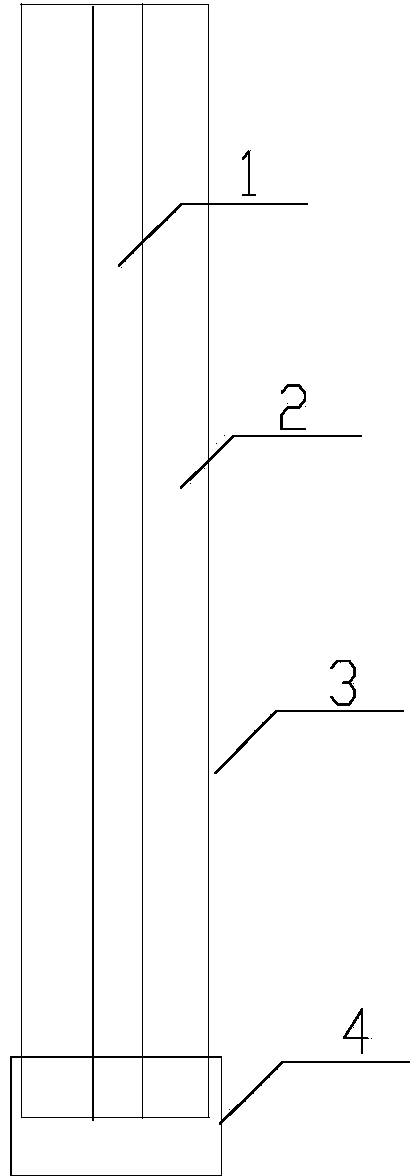

[0036] Such as figure 1 Shown: a vacuum panel, the main body of the vacuum panel is a skeleton 2; several drainage grooves 5 are provided on the skeleton 2, and a vacuum drainage channel 1 is also provided; the surface of the skeleton 2 is covered with a permeable water-permeable layer 3; the vacuum The end of the plate is provided with a joint 4, and there is a cavity inside the joint 4, and a closed structure is formed between the joint 4 and the end of the vacuum plate, and the end of all drainage grooves 5 on the skeleton 2 and the end of the vacuum drainage channel 1 and the cavity of the joint 4 Connected; the top of the vacuum drainage channel 1 is connected to the vacuum pipe network. The skeleton material 2 is plastic or steel pipe; the permeable material 3 is geotextile.

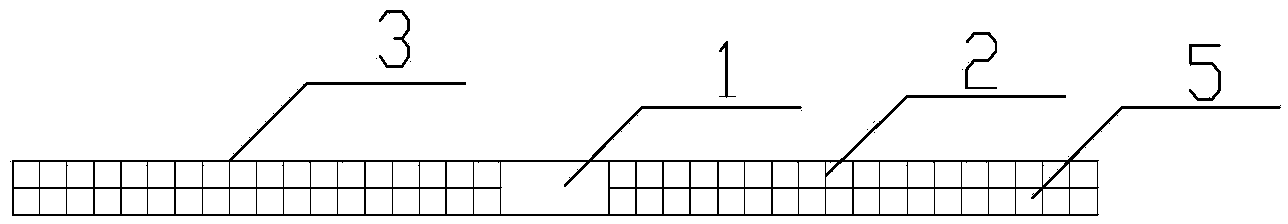

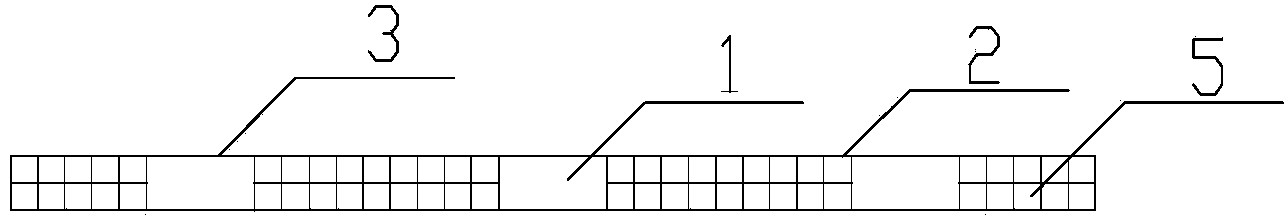

[0037] Such as Figure 2-4 As shown, the cross-section of the vacuum drainage channel 1 is rectangular, the number of the vacuum drainage channel 1 can be one or several, and the relative positio...

Embodiment 2

[0041] In this embodiment, the volume of the drying pool is 10m 3 , the specific steps are as follows:

[0042] (1) Pre-treatment: transport Taihu Lake silt to the drying tank for preliminary sedimentation, and lay woven cloth on the mud surface;

[0043] (2) Vacuum board setting: Insert several vacuum boards in the sludge obtained in step (1), and connect the airtight vacuum drainage channels in the vacuum boards to the vacuum pipe network;

[0044] (3) Vacuuming: Lay geotextiles on the silt where the vacuum board is laid in step (2) to protect the vacuum pipe network, and seal it with a sealing film;

[0045] (4) Vacuuming: Vacuumize the vacuum plate through the vacuuming pipe network until the water output is obviously less and the mud surface has no obvious drop and change; stop vacuuming;

[0046] (5) Post-treatment: After the sealing film is uncovered, the top of the vacuum plate is connected to the atmosphere, and the suction treatment is continued to accelerate the f...

Embodiment 3

[0051] In this embodiment, the volume of the drying tank is 100m 3 , the specific steps are the same as in Example 1.

[0052] The specific parameters are shown in Table 2.

[0053] Table 2

[0054] The initial mud content of silt

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com