Air spinning machine

A technology of air spinning and drafting device, applied in spinning machine, continuous winding spinning machine, textile and papermaking, etc., can solve the problems of sliver separation, fiber deviation, etc., achieve uniformity and accurate parallel position , the effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

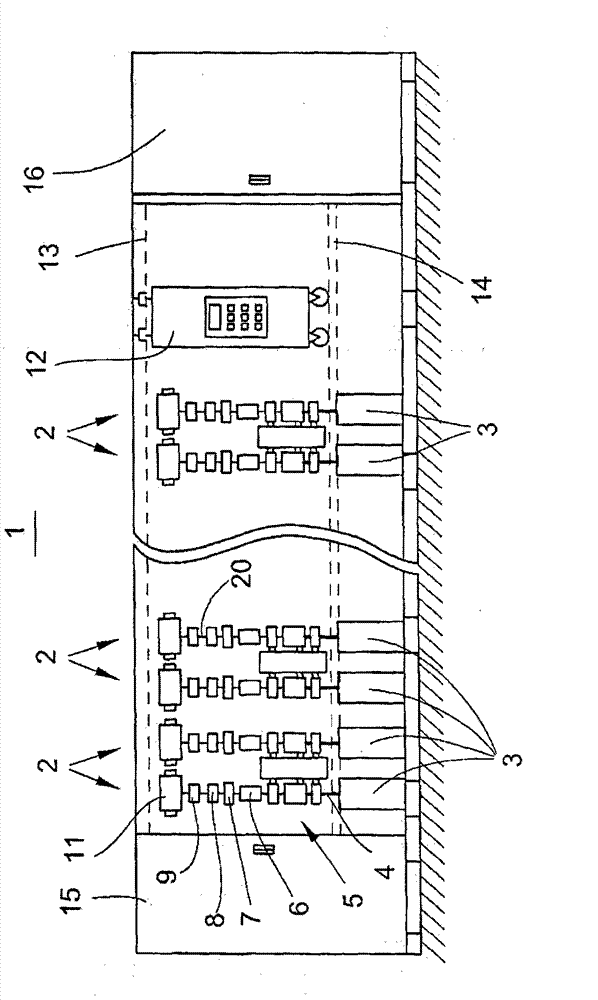

[0024] figure 1 A front view of the air spinning machine 1 is schematically shown. The textile machine has a plurality of work stations or spinning stations 2 arranged next to each other, which are positioned between so-called end frames 15 , 16 arranged on the end sides.

[0025] like figure 1 It is further shown that each station 2 is equipped with feed material, for example a sliver 4 stored in a spinning barrel 3 .

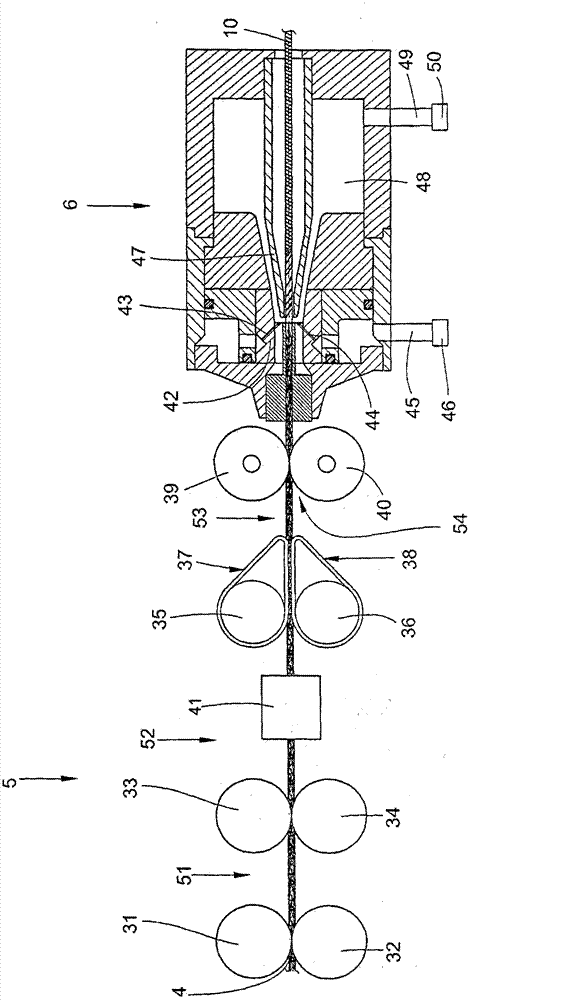

[0026] In addition, each station 2 also has a drafting device 5, an air spinning device 6, a yarn unwinding device 7, a yarn clearer 8 and a winding device.

[0027] The associated yarn traversing device 9 serves to wind the yarn 10 produced from the sliver 4 in the rotor spinning unit 6 onto the winding bobbin 11 in interdigitated layers.

[0028] The winding bobbin or cross-winding bobbin 11 is usually held on a creel (not shown) and is rotated by a bobbin drive (also not shown).

[0029] like figure 1 It is further shown that the workstation 2 of the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com