Double-core cuprous iodide complex luminescent material

A luminescent material, cuprous iodide technology, applied in luminescent materials, copper organic compounds, chemical instruments and methods, etc., can solve the problems of insufficient luminous efficiency and thermal stability of luminescent materials, scarcity of materials with superior performance, etc., to achieve energy Improved transmission efficiency, low production cost, and the effect of suppressing non-radiative attenuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Dinuclear cuprous iodide complex [CuI(DPPP)] 2 Preparation of:

[0028] 1) Each weighed 0.3mmol of DPPP, poured it into a Shenlek bottle, added 30ml of dichloromethane, filled with nitrogen, and stirred thoroughly to obtain a clear solution A;

[0029] 2) Weigh 0.3 mmol of CuI with a stoichiometric ratio of 1:1, pour it into solution A, continue to react under a nitrogen atmosphere, and stir in the dark for 6 hours to obtain a colorless slightly turbid solution B;

[0030] 3) Filter solution B, take its filtrate, and remove the solvent by rotary evaporation of the filtrate under reduced pressure to obtain a white microcrystalline powder product, which is dried to obtain Cu(I) complex luminescent material [CuI(DPPP)] 2 .

Embodiment 2

[0032] Dinuclear cuprous iodide complex [CuI(DPPP)] 2 Single crystal acquisition and characterization:

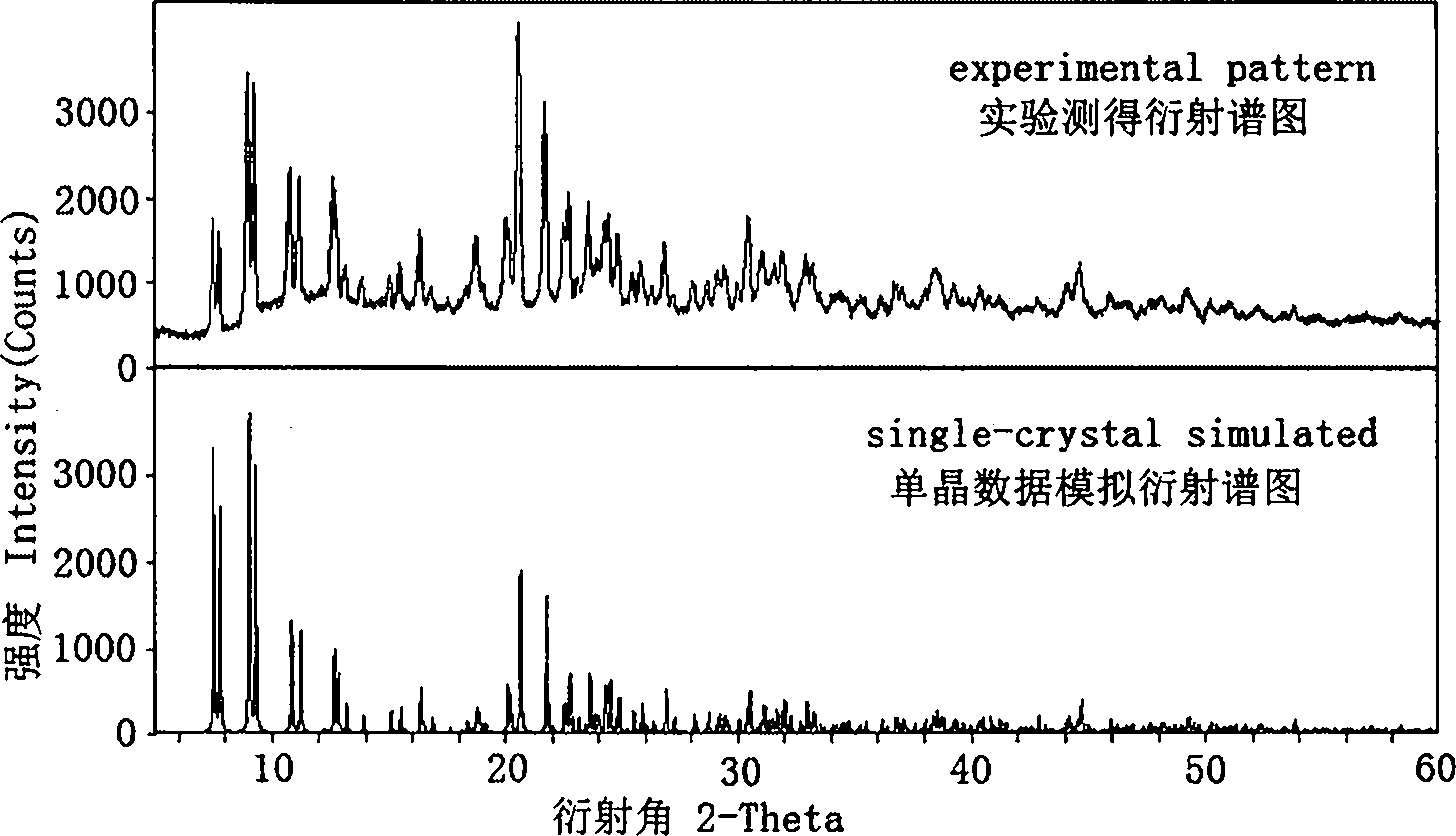

[0033] The single crystal was obtained by solvent diffusion method, and 0.1 mmol of [CuI(DPPP)] was weighed 2Powder, dissolved in 1ml of dichloromethane, placed in a small test tube, slowly added isopropanol (the volume ratio of isopropanol to dichloromethane solution is 1.5:1), and left to stand for several days to obtain a colorless transparent block shape crystal, select a single crystal with a size of 0.20×0.13×0.12mm for X-ray single crystal diffraction, and analyze [CuI(DPPP)] 2 molecular structure. The molecular structure of the compound is shown in the attached figure 1 , the unit cell packing structure is shown in the appendix figure 2 .

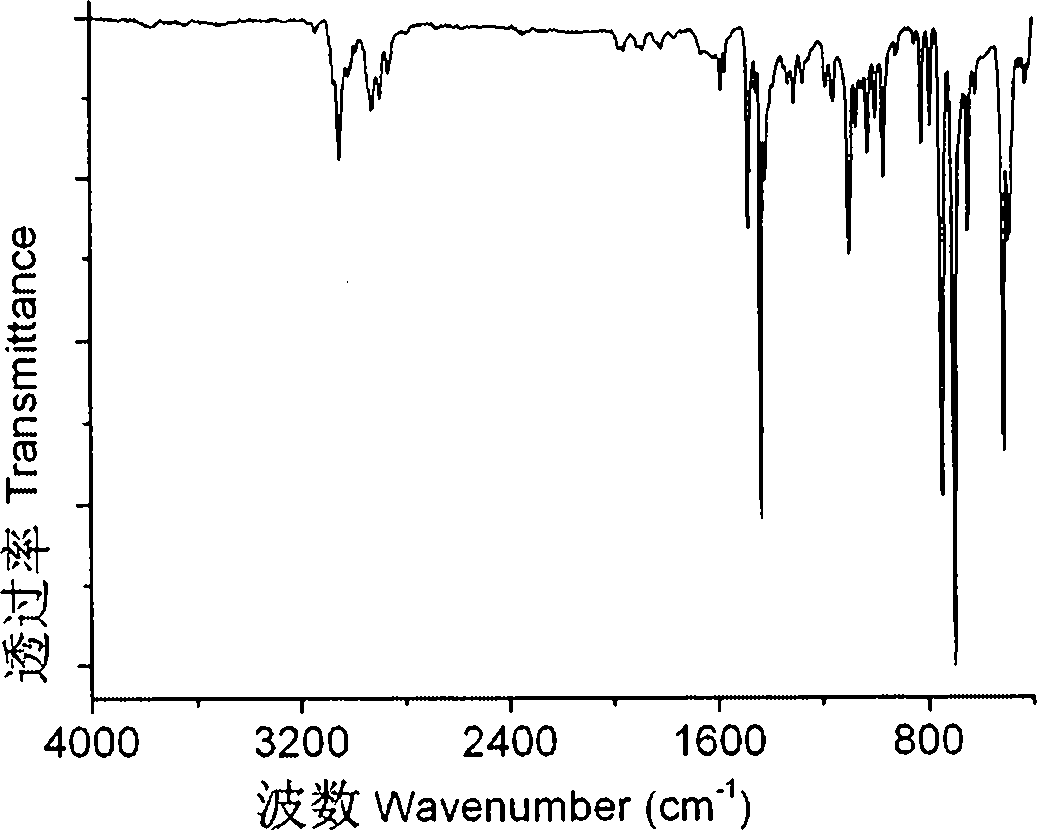

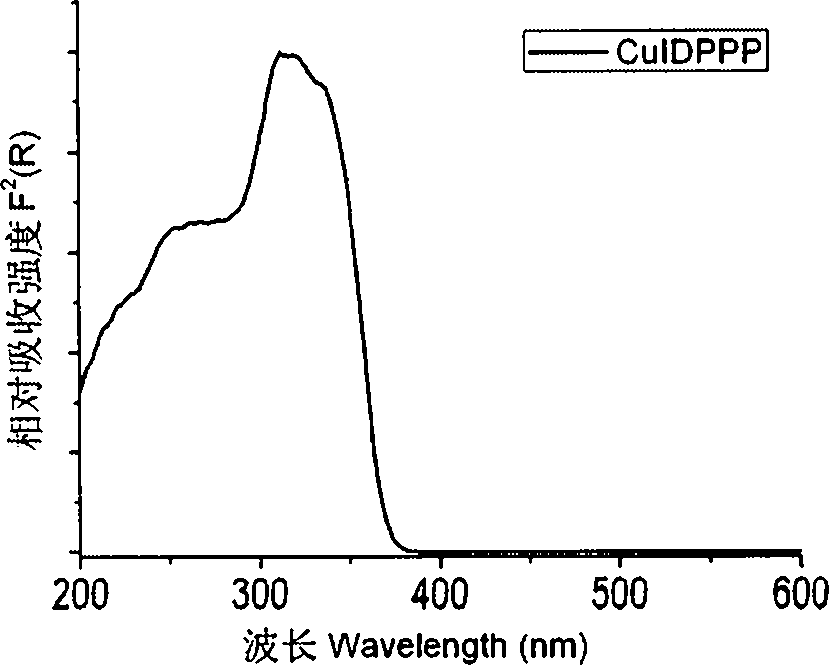

[0034] For dinuclear complexes [CuI(DPPP)] 2 A series of performance tests were carried out on pure phase crystal samples. TG test shows that the material has good thermal stability, and its initial decomposition temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com