Oxydative degradation starch grafted polycarboxylate superplasticizer and preparation method thereof

A technology of oxidative degradation and branch polycarboxylic acid, which is applied in the field of cement concrete admixture, can solve the problems of different molecular weight distribution, large molecular structure difference, low starch reaction efficiency, etc., achieve high-efficiency and stable dosage, reduce carbon emissions, and easily obtain raw materials sustainable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

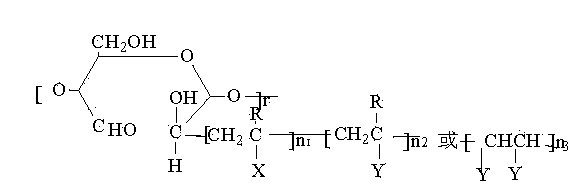

Image

Examples

Embodiment 1

[0030] Add 300 parts by mass of water to a reaction kettle connected with an ultrasonic stirrer, and add 100 parts by mass of ordinary cornstarch under the stirring of an ultrasonic stirrer (20KHz, power 2000W). The reactants became a translucent solution. Add 15 parts by mass of hydrogen peroxide, and ultrasonically stir for 20 minutes, then dropwise add a mixture of 10 parts by mass of acrylamide, 20 parts by mass of acrylic acid and 10 parts by mass of sodium propylene sulfonate while ultrasonically stirring. After the dropwise addition, continue to react for 3 hours , use 40% sodium hydroxide solution to adjust the pH value to 7-8, add water to dilute to a total mass fraction of 20%, and obtain the oxidatively degraded starch grafted polycarboxylate superplasticizer product.

[0031]The oxidative degradation starch grafted polycarboxylate superplasticizer made in Example 1 is subjected to the clean slurry test according to the current national standard. When the dosage is ...

Embodiment 2

[0033] Add 400 parts by mass of water to the reaction kettle connected with an ultrasonic stirrer, and add 100 parts by mass of wheat starch under the stirring of the ultrasonic stirrer (20KHz, power 2000W). The substance becomes a transparent solution. Add 15 parts by mass of hydrogen peroxide, and after ultrasonic stirring for 20 minutes, dropwise add a mixture of 10 parts by mass of acrylamide, 20 parts by mass of methacrylic acid and 10 parts by mass of sodium methacryl sulfonate while ultrasonically stirring. After the addition is complete, After continuing to react for 3 hours, adjust the pH value to 7-8 with 40% sodium hydroxide solution, add water to dilute to a total mass fraction of 20%, and obtain the oxidatively degraded starch-grafted polycarboxylate superplasticizer product.

[0034] The oxidative degradation starch grafted polycarboxylate superplasticizer made in Example 2 is subjected to the clean slurry test according to the current national standard. When the...

Embodiment 3

[0036] In the reaction kettle connected with an ultrasonic stirrer, add 200 parts by mass of water, under the stirring of the ultrasonic stirrer (20KHz, power 2000W), add 100 parts by mass of potato starch, wait for uniform dispersion, gelatinize at 65°C until reaction The substance becomes a transparent solution. Add 10 parts by mass of hydrogen peroxide, and after ultrasonic stirring for 25 minutes, dropwise add a mixture of 10 parts by mass of acrylamide, 20 parts by mass of methacrylic acid and 10 parts by mass of maleic anhydride while ultrasonically stirring, and continue the reaction for 1.5 After h, use 40% sodium hydroxide solution to adjust the pH value to 7-8, add water to dilute to a total mass fraction of 20%, and obtain the oxidatively degraded starch grafted polycarboxylate superplasticizer product.

[0037] The oxidative degradation starch grafted polycarboxylate superplasticizer made in Example 3 is subjected to the clean slurry test according to the current n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com