Material bag self-weighing, self-detecting and self-classifying stacking device for stacker crane

A technology of material package and palletizer, which is applied in the field of material package palletizer, material package weight self-scale, self-inspection and self-classification palletizing device, which can solve the problems of increased trouble, inability to implement separate stacking, and increased labor costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below through the description of specific embodiments with reference to the accompanying drawings.

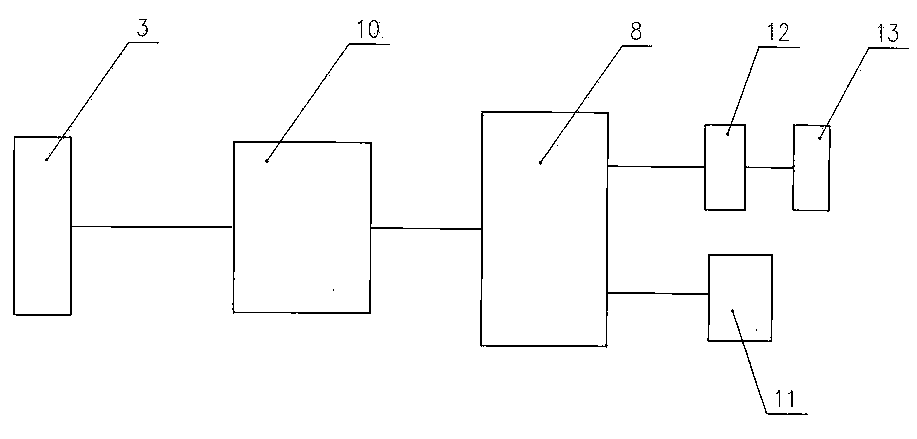

[0019] A typical specific implementation, as attached figure 1 , 2 and 3.

[0020] A material package weight self-scale self-inspection self-classification palletizing device of a palletizer, including a gripper assembly 7, and an intelligent controller 8 with control software, and it:

[0021] It also includes the first connecting piece 1 connected with the cantilever screw of the palletizer, the second connecting piece 2, the weighing sensor 3, the third connecting piece 4 screwed with the cover plate 7-1 of the gripper assembly 7, and the retaining ring 5 , the connecting column 6 and the lifting screw 9; the upper and lower sides of the second connecting piece 2 are respectively screwed with the first connecting piece 1 and the load cell 3 (the first connecting piece 1 can also be connected with the load cell 3 direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com