Plastic bottle cap

A technology of plastic and bottle caps, which is applied in the directions of closure, packaging, transportation and packaging, etc. It can solve the problems of easy dumping on the cap seat, difficult flow control, pollution of the cap seat and bottle mouth, etc., so as to achieve the convenience of pouring liquid and avoid Liquid splash, guaranteed cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

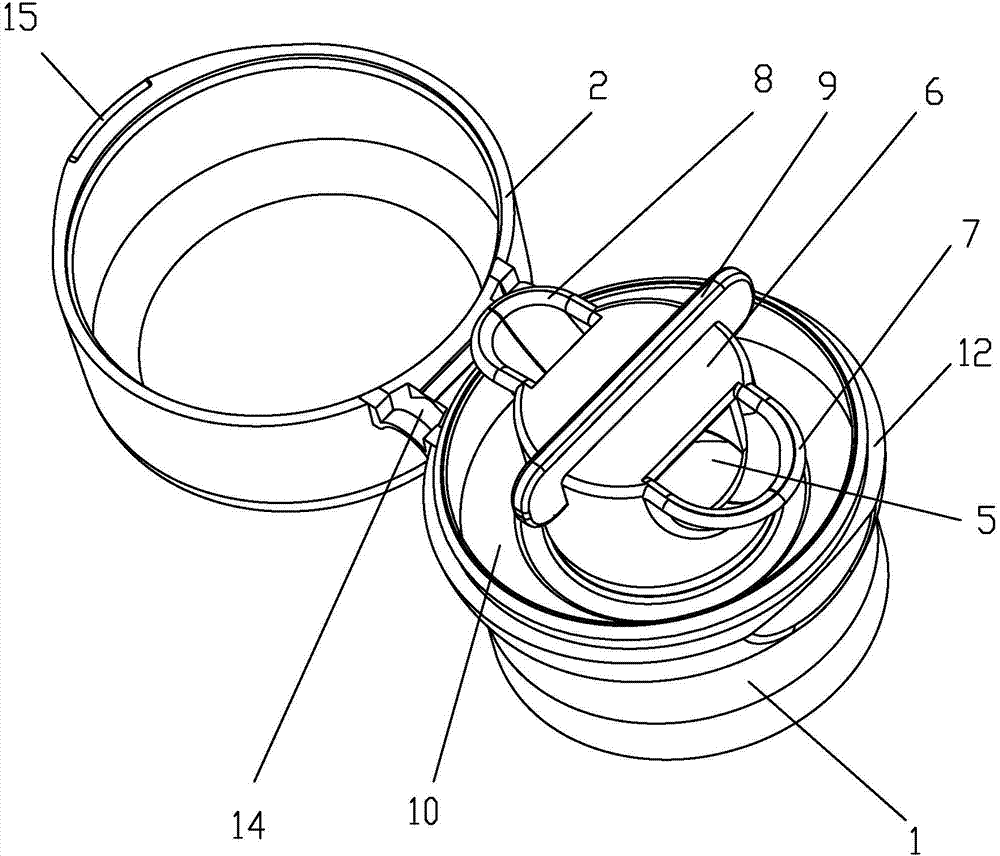

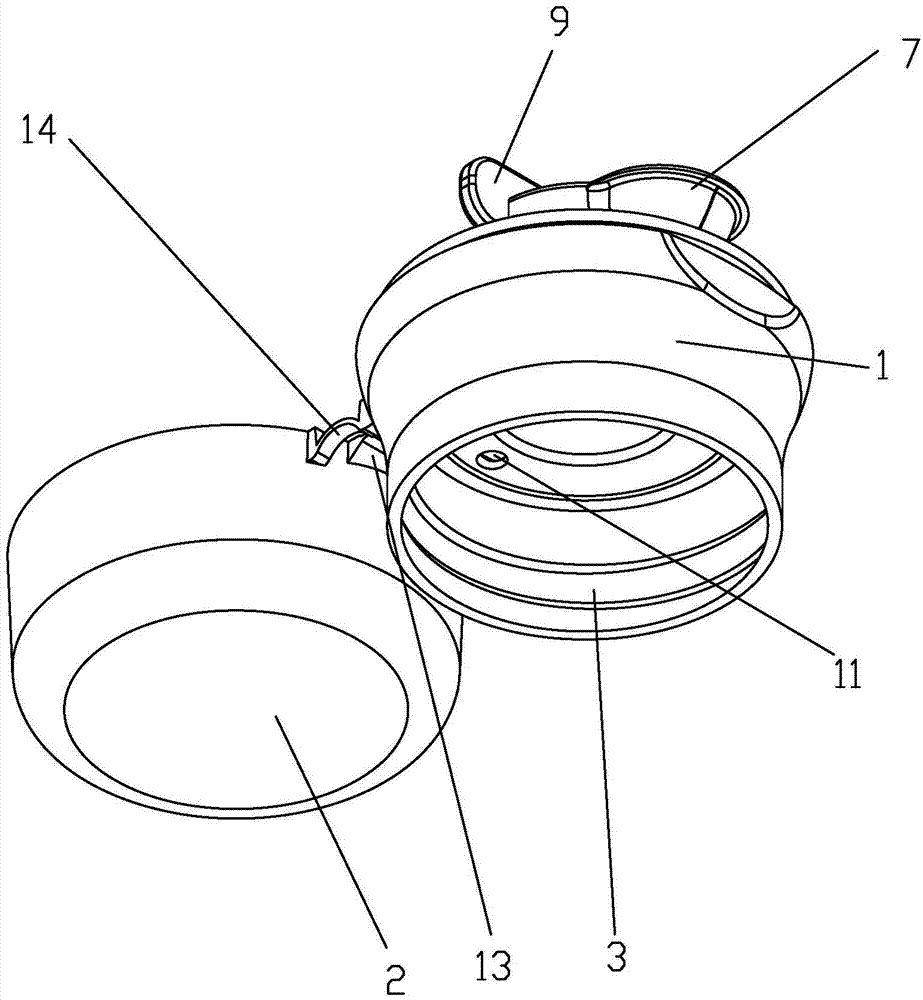

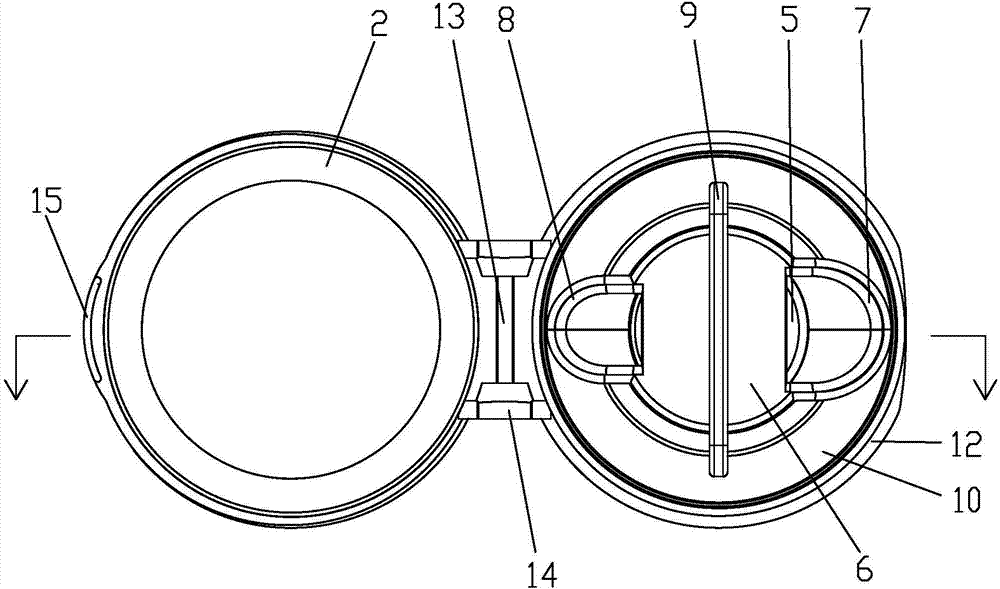

[0027] The present invention will be further described below in conjunction with accompanying drawing:

[0028] A plastic bottle cap capable of changing the flow rate of the liquid, comprising a cap base 1, the cap base 1 is provided with a cover body 2 that can be fastened with the cap base 1, and the cap base 1 is also provided with a bottle mouth Connected interface 3, the interface 3 is threadedly connected with the bottle mouth. The cover 1 is provided with a boss 4, the boss 4 is provided with a boss cavity 18 communicating with the interface 3, and the side wall of the boss 4 is provided with an inner outlet communicating with the boss cavity 18. Liquid port 5, the boss 4 is covered with an inner cover 6 that can rotate around the boss 4, and the side wall of the inner cover 6 is provided with an outer liquid outlet 19 that can overlap or stagger with the inner liquid outlet 5. The overlapping area of the outer liquid outlet 19 and the inner liquid outlet 5 changes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com