Vertical-lifting device with combined propellers

A technology of combined propellers and blades, which is applied in transportation and packaging, rotorcraft, aircraft, etc., can solve the problems of rare application examples of cycloidal propellers, reduce the overall size of the airframe and shipboard space, and improve the structure Strength, the effect of shortening the blade length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Preferred embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

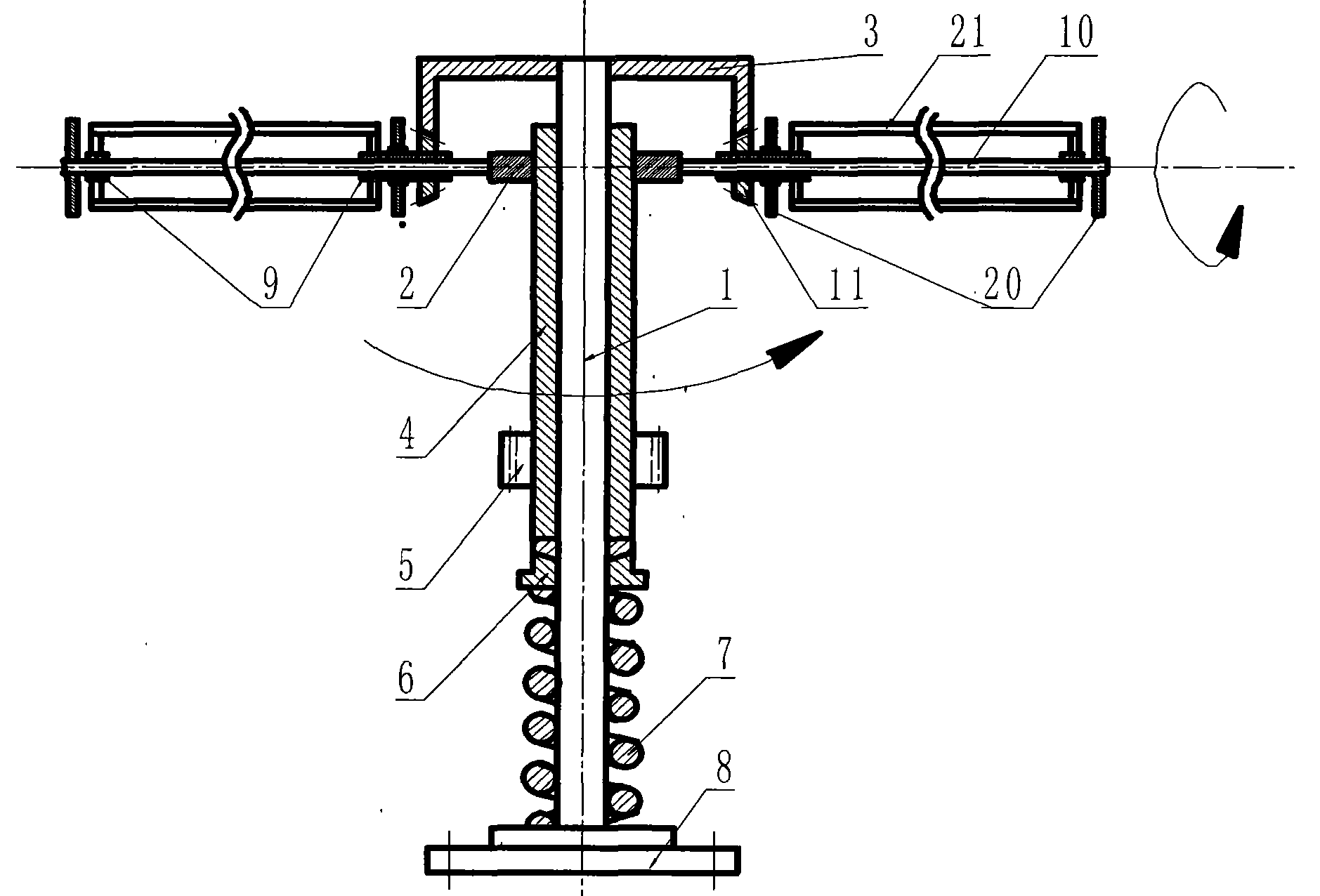

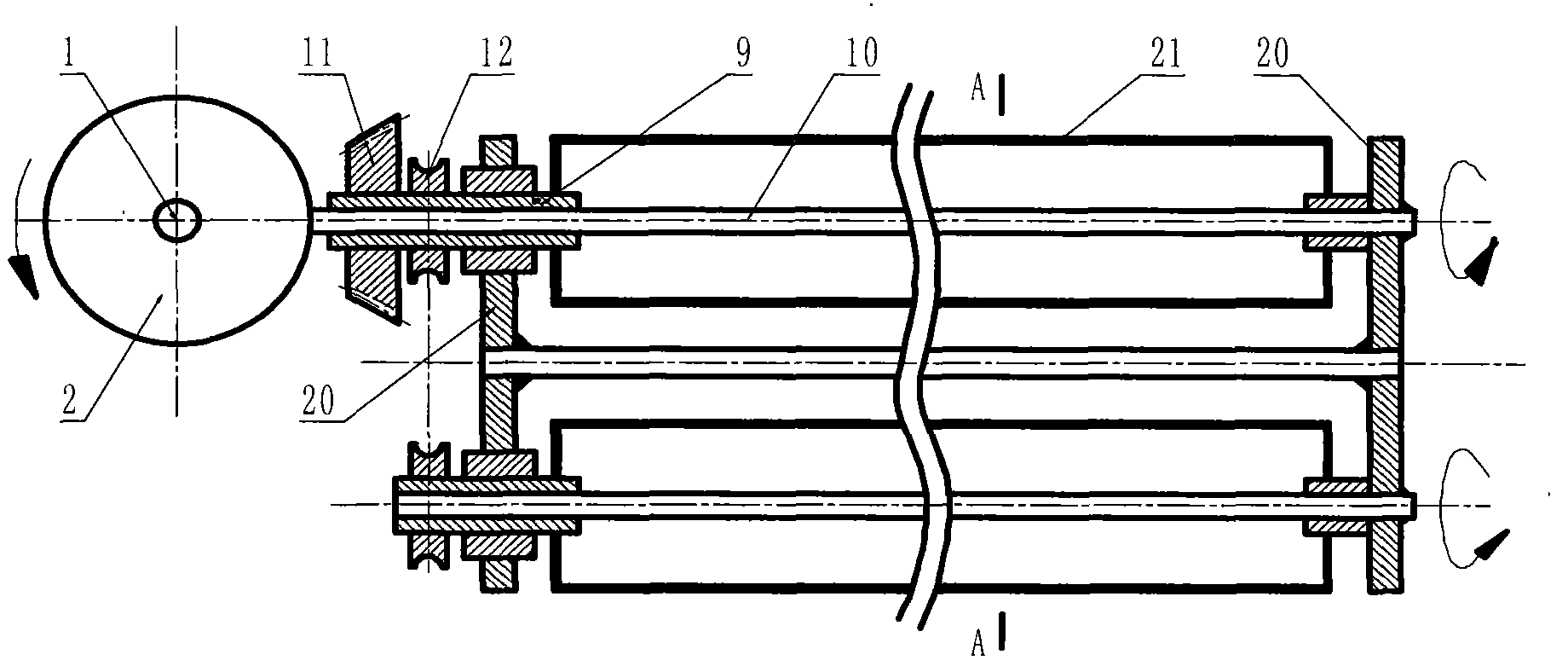

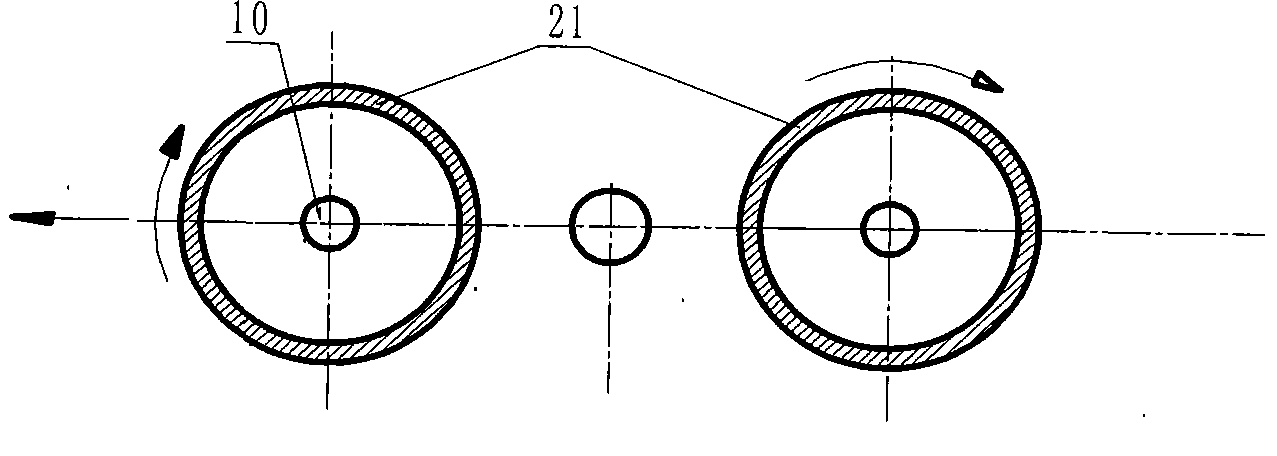

[0040] Such as figure 1 As shown, an orthogonal rotation mechanism of a helicopter with combined blades includes: a vertical shaft 1, a rotor hub 2, a fixed bevel gear 3, a revolution shaft sleeve 4, a revolution drive wheel 5, a thrust bearing 6, and a buffer spring 7 , vertical shaft seat 8, rotation shaft sleeve 9, blade shaft 10 and movable bevel gear 11; wherein, the lower end of the vertical shaft 1 is fixedly connected with the helicopter body by means of the vertical shaft seat 8, and the fixed bevel gear with the tooth shape facing downward is fixed on the top coaxial line 3. The revolving bushing 4 is rotatably matched with the vertical shaft 1, and the outer part of the former is fixed with the coaxial rotor hub 2 and the revolving drive wheel 5 from top to bottom, and the lower end is equipped with a thrust bearing 6 supported on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com