Improved auxiliary frame of large-earthwork concrete mixing carrier

A technology for mixing transport trucks and concrete, which is applied in the direction of concrete transportation, transportation and packaging, and vehicle parts, etc. It can solve the problems of increased load on the mixer truck and easy fracture of the sub-frame, so as to optimize the stress situation and improve the bending and torsion performance , to avoid the effect of stress concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

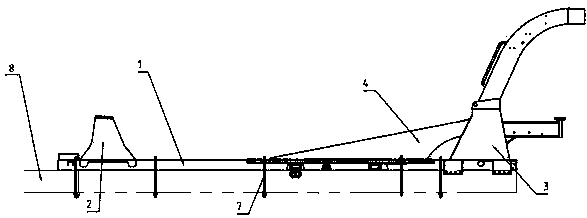

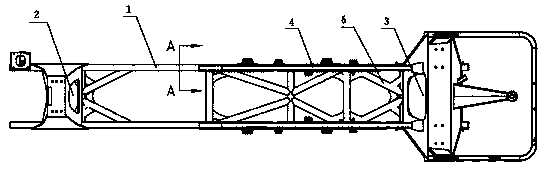

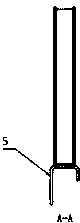

[0016] Referring to the attached drawings, the sub-frame of a large volume concrete mixer truck of the present invention will be described in detail below.

[0017] Such as figure 1 , figure 2 , image 3 As shown, the subframe of a large-scale concrete mixer truck of the present invention includes a subframe 1, a front desk 2, a backstage 3, a brace 4, a U-shaped curved plate 5 and a brace 6. The subframe Beam 1 is located at the bottom of the entire sub-frame and is placed on the chassis 8 of the mixer truck. The sub-beam 1 is mainly composed of two square tubes as the skeleton and the connection between the two square tubes; the front desk 2 is arranged on the sub-frame. One end above the beam 1, the backstage 3 is arranged at the other end above the subbeam 1, the U-shaped curved plate 5 is arranged on the subbeam, and a diagonal brace is arranged between the U-shaped curved plate and the backstage, A "herringbone"-shaped diagonal brace 6 is arranged between the sub-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com