Through-curve anti-deflection mechanism for sanding device at end part of locomotive car body

A sand spreading device and anti-deflection technology, which is applied in locomotives and other directions, can solve the problems of insufficient traction, inability to effectively improve the adhesion coefficient between wheel and rail, idling, etc., and achieve the effect of improving the adhesion coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

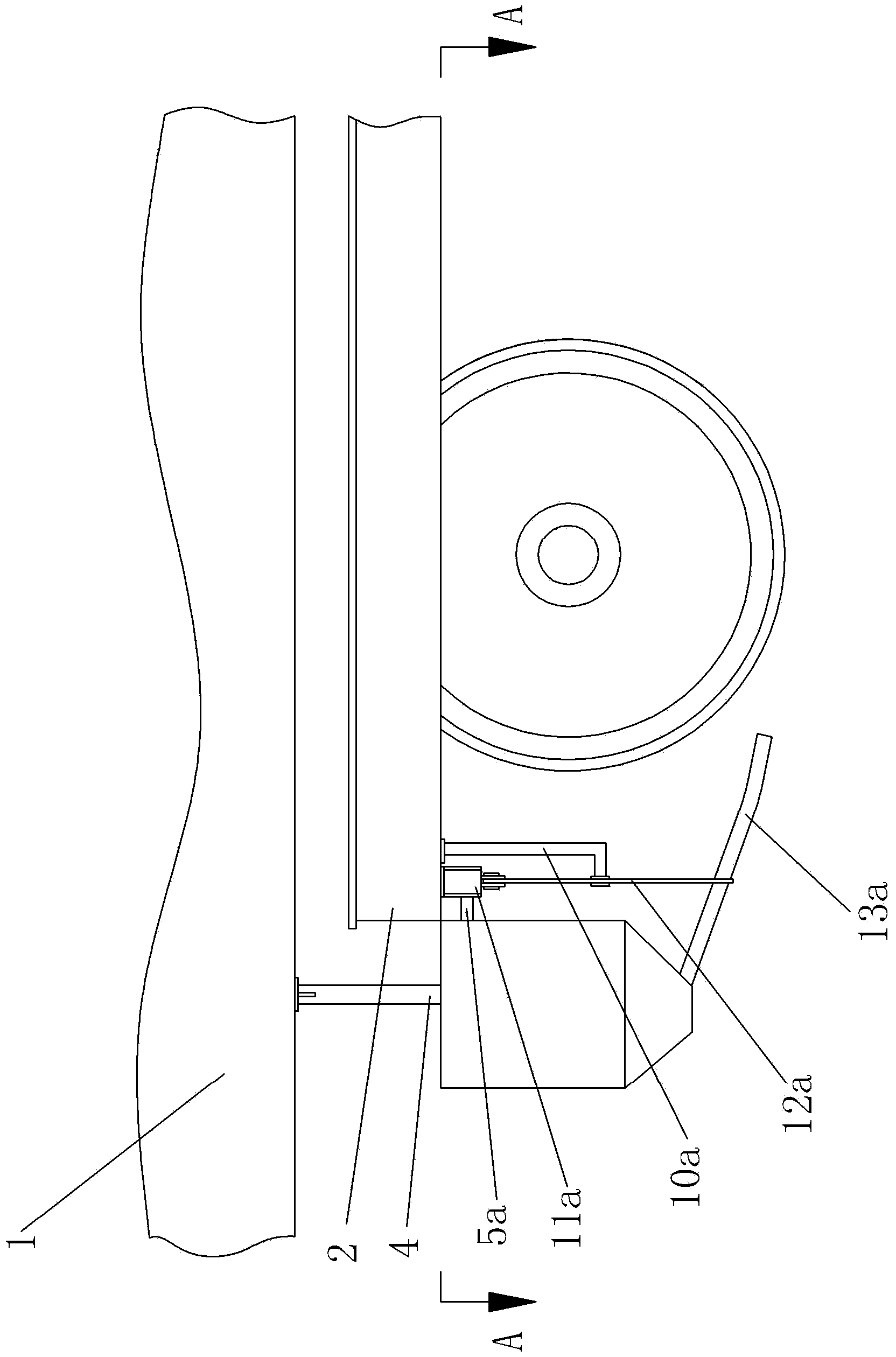

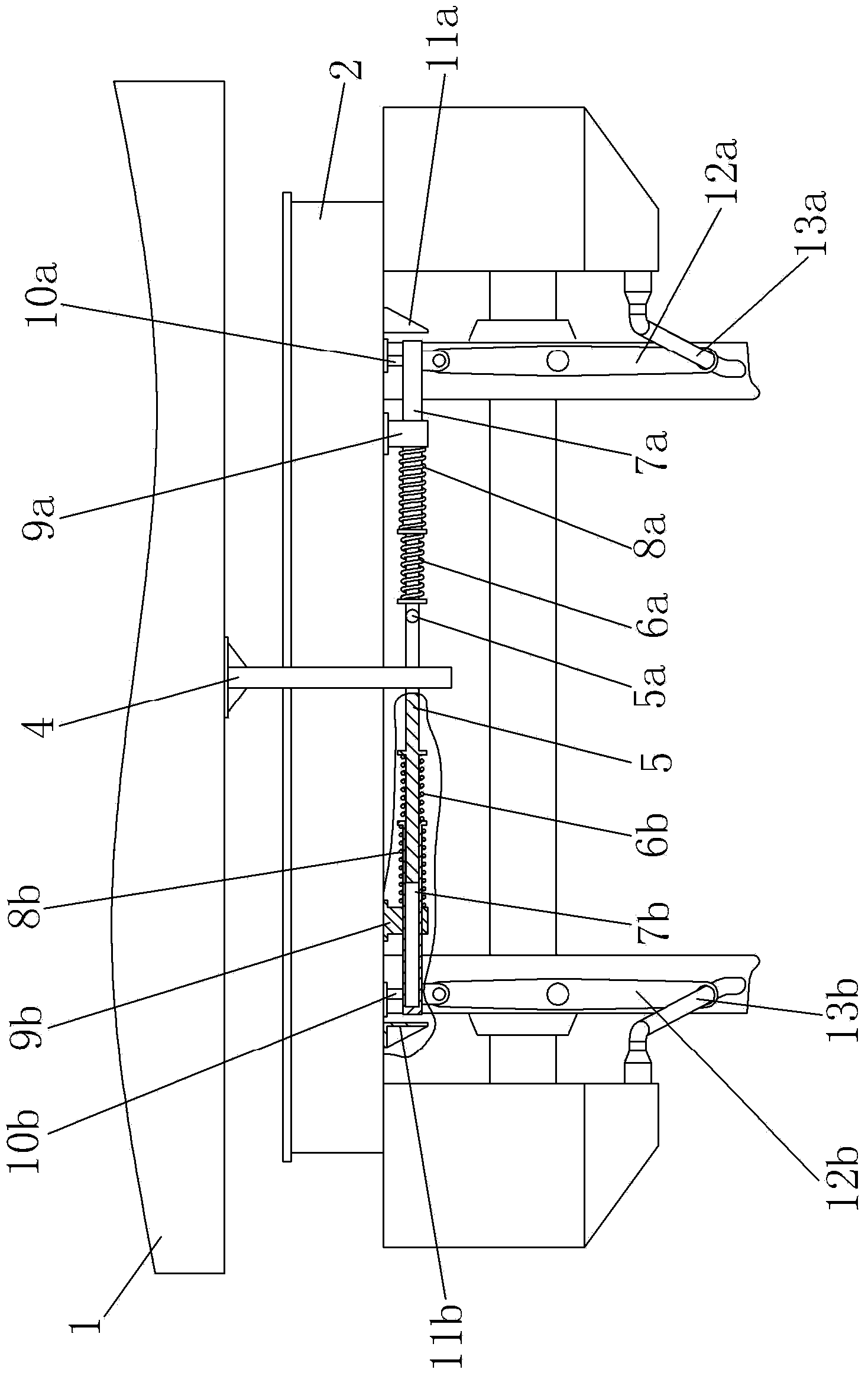

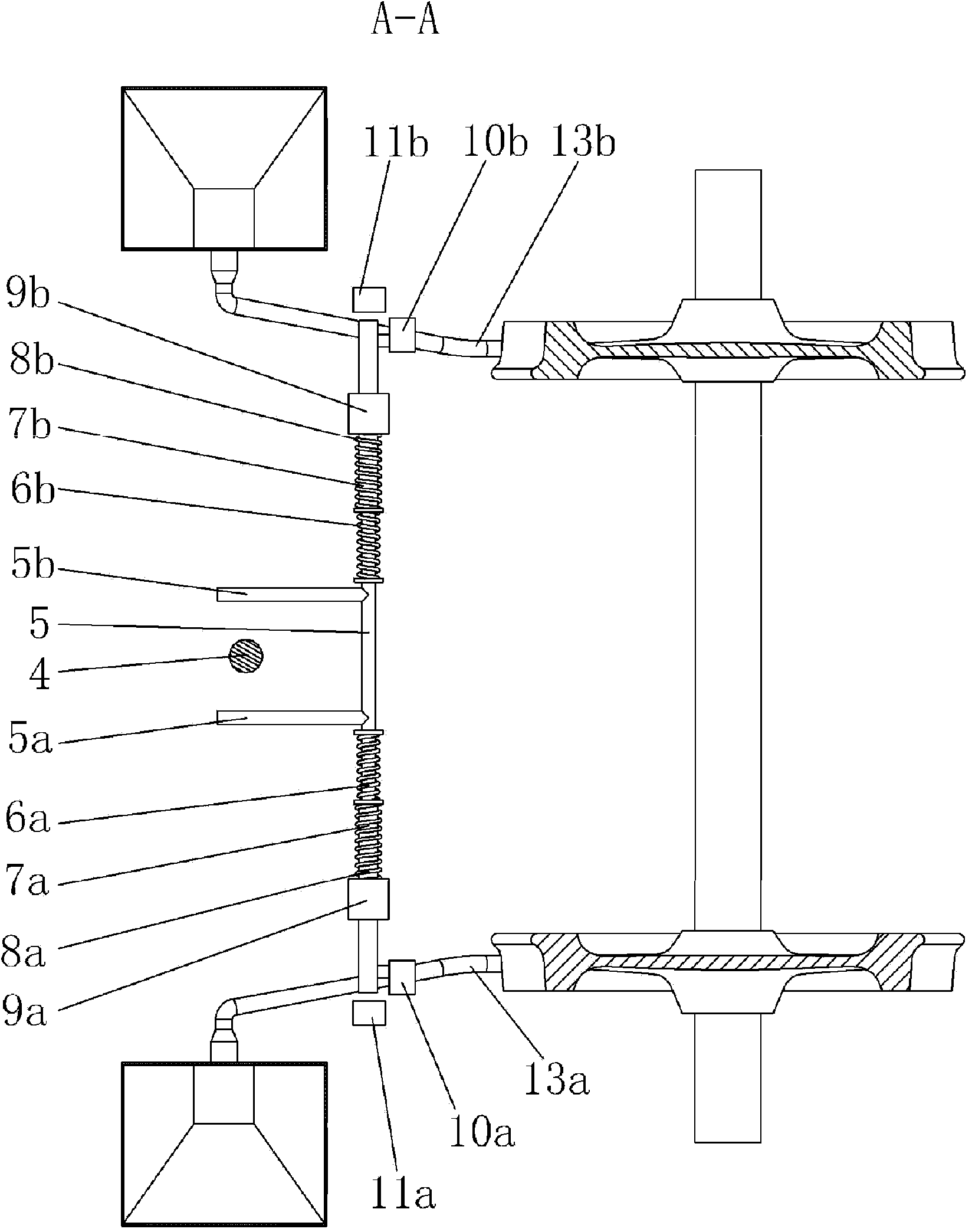

[0027] Figure 1~3 It is shown that a specific implementation of the present invention is a curved anti-deflection mechanism of a sand spreading device at the end of a locomotive body, wherein:

[0028] The middle part of the right sanding hose 13a of the sanding device at the end of the locomotive body 1 is matched with the hose connection hole at the lower end of the right reversing lever 12a. The middle part of the right reversing lever 12a is hinged on the right positioning rod 10a, and the right positioning rod 10a The upper end is rigidly connected to the end beam 2 of the locomotive frame; the upper end of the right reversing lever 12a is hinged to the right end of the lateral right sleeve 7a, and the middle of the right sleeve 7a is sheathed in the right sleeve seat 9a at the lower part of the end beam 2. In the cavity, the right sleeve return spring 8a is sleeved between the left end of the right sleeve 7a and the right sleeve seat 9a; the inner cavity of the right sleev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com