Control method based on cascade multilevel ground electrical phase-splitting device

A cascaded multi-level, over-power phase separation technology, applied in power lines, transportation and packaging, vehicle components, etc., can solve the problems of production cut-off over-voltage, auxiliary system over-current, and high switching requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with drawings and embodiments.

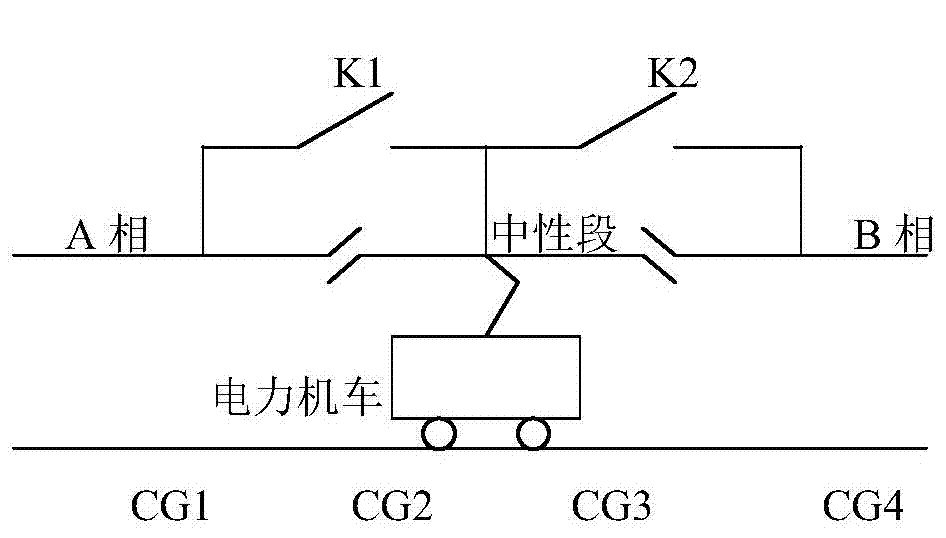

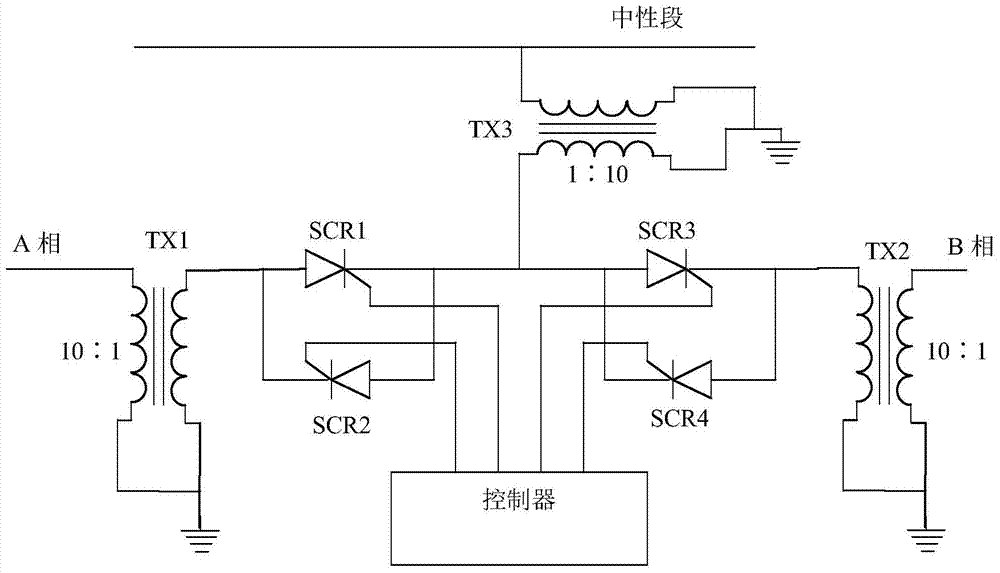

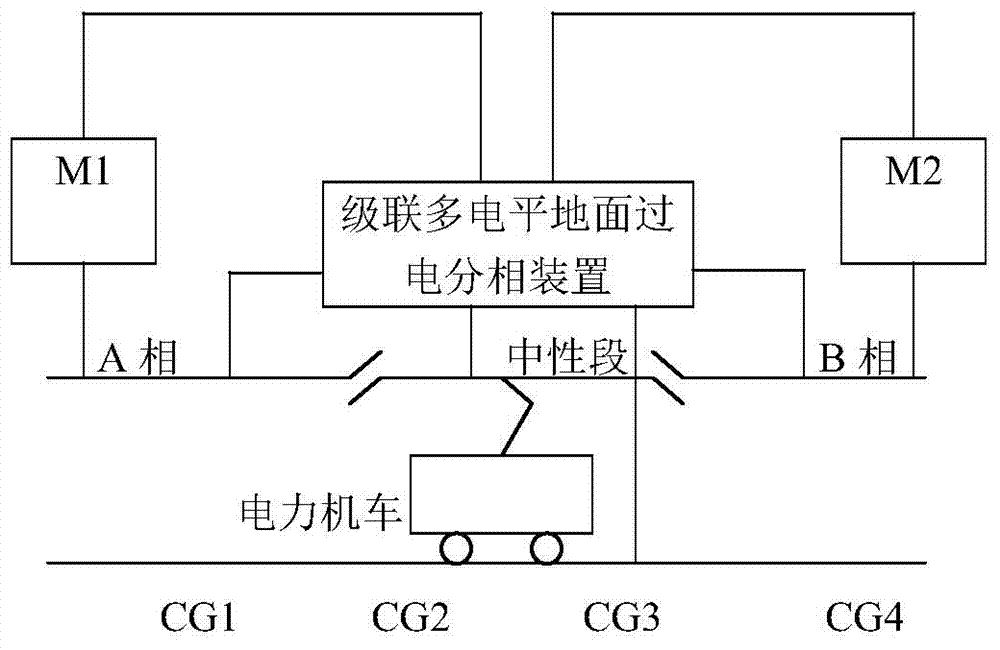

[0019] According to the determination of locomotive position by locomotive position sensors CG1, CG2, CG3 and CG4 on the track and the determination of catenary A and B phase voltage phases by catenary voltage phase detection modules M1 and M2 for measuring the catenary voltage phase , the output voltage is controlled by the controller of the cascaded multi-level ground over-current phase-splitting device to realize the flexible passing of the electric locomotive through the phase-separation; image 3 As shown, the specific implementation of the control method is as follows:

[0020] 1. When the train runs from CG1 to CG4,

[0021] 1) When the electric locomotive (or EMU) reaches CG1, control the output of the cascaded multi-level inverter so that the amplitude, frequency and phase of the output voltage are consistent with the A-phase bridge arm;

[0022] 2) After the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com