Mold with heating-steering lifter mechanism for forming SMC (sheet molding compound) product

A technology of inclined top mechanism and rotating mechanism, which is applied in the field of molds with heating and steering inclined top mechanism, which can solve the problems of unsmooth sliding, jamming, separation, etc., and achieve the effects of not easy to jam, smooth sliding, and difficult to separate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

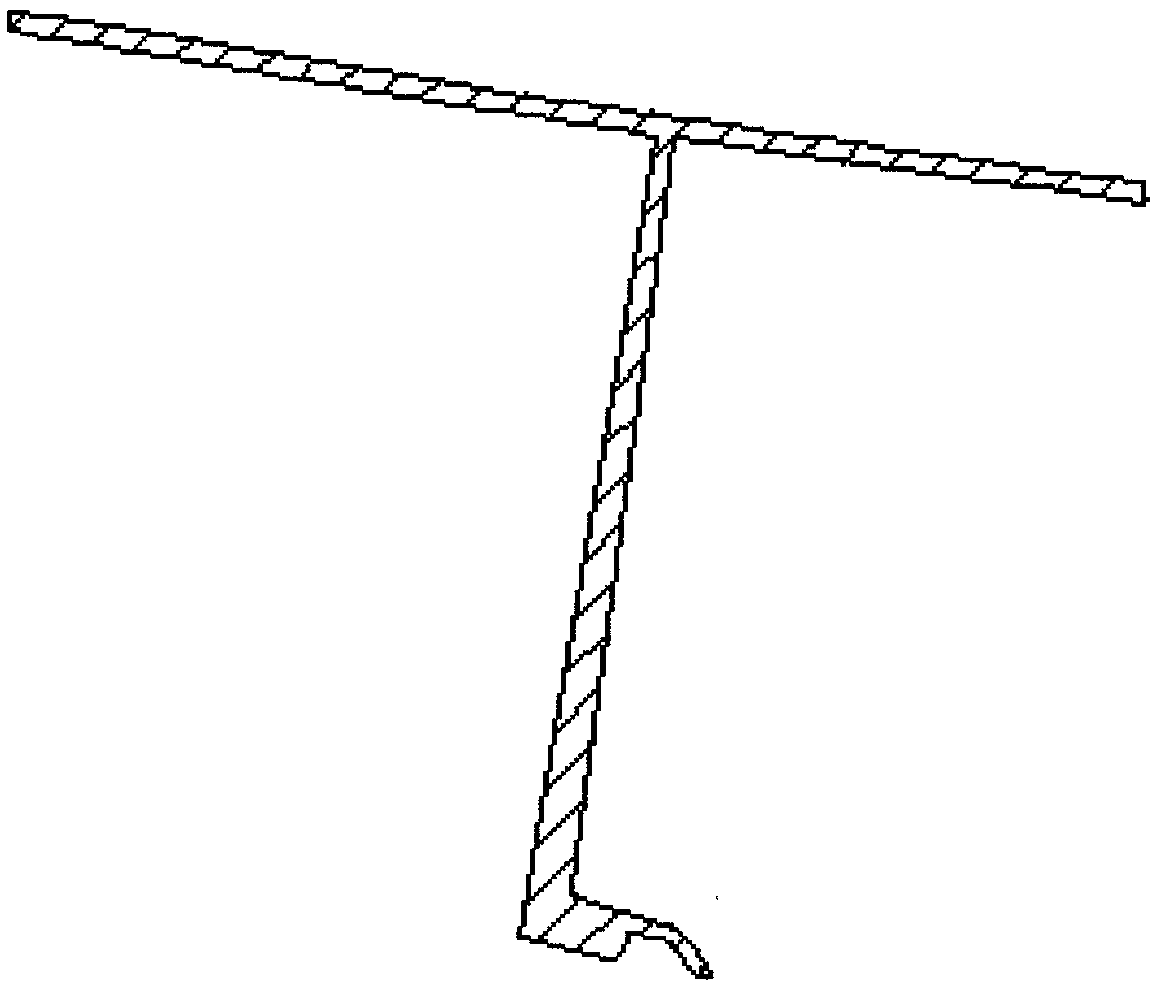

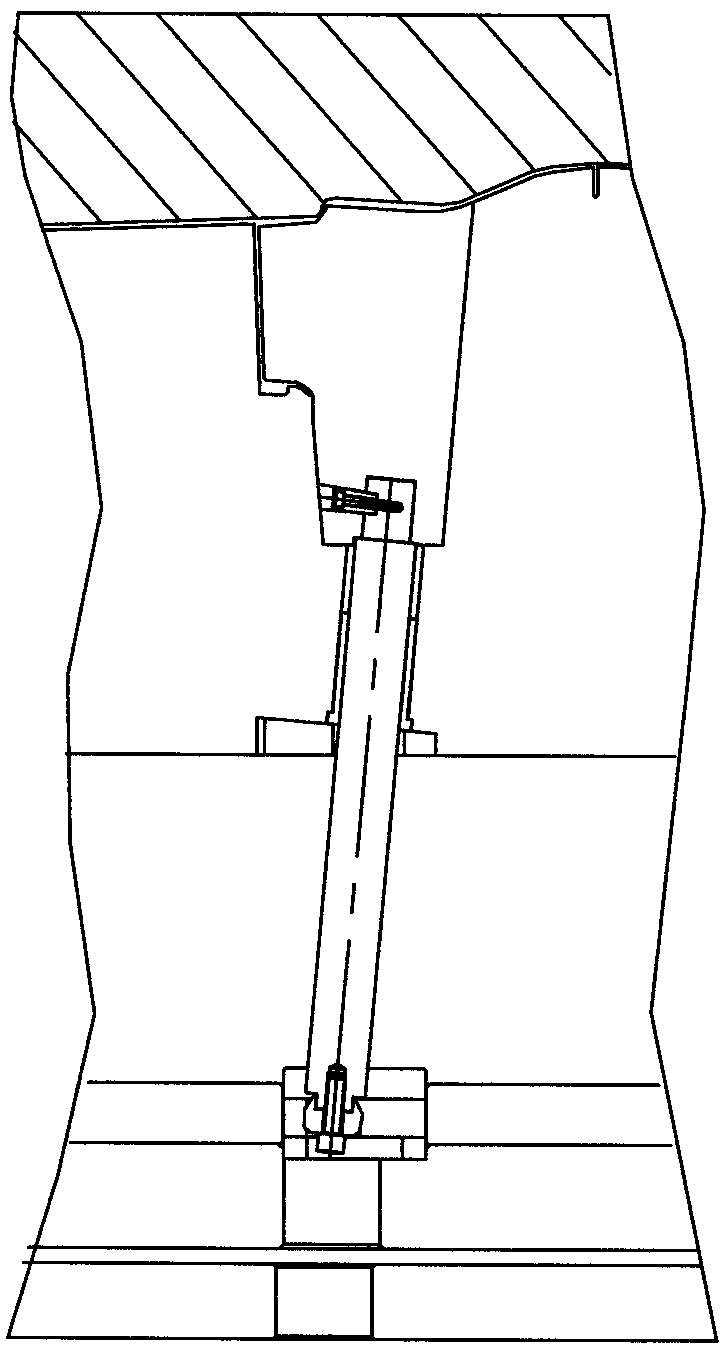

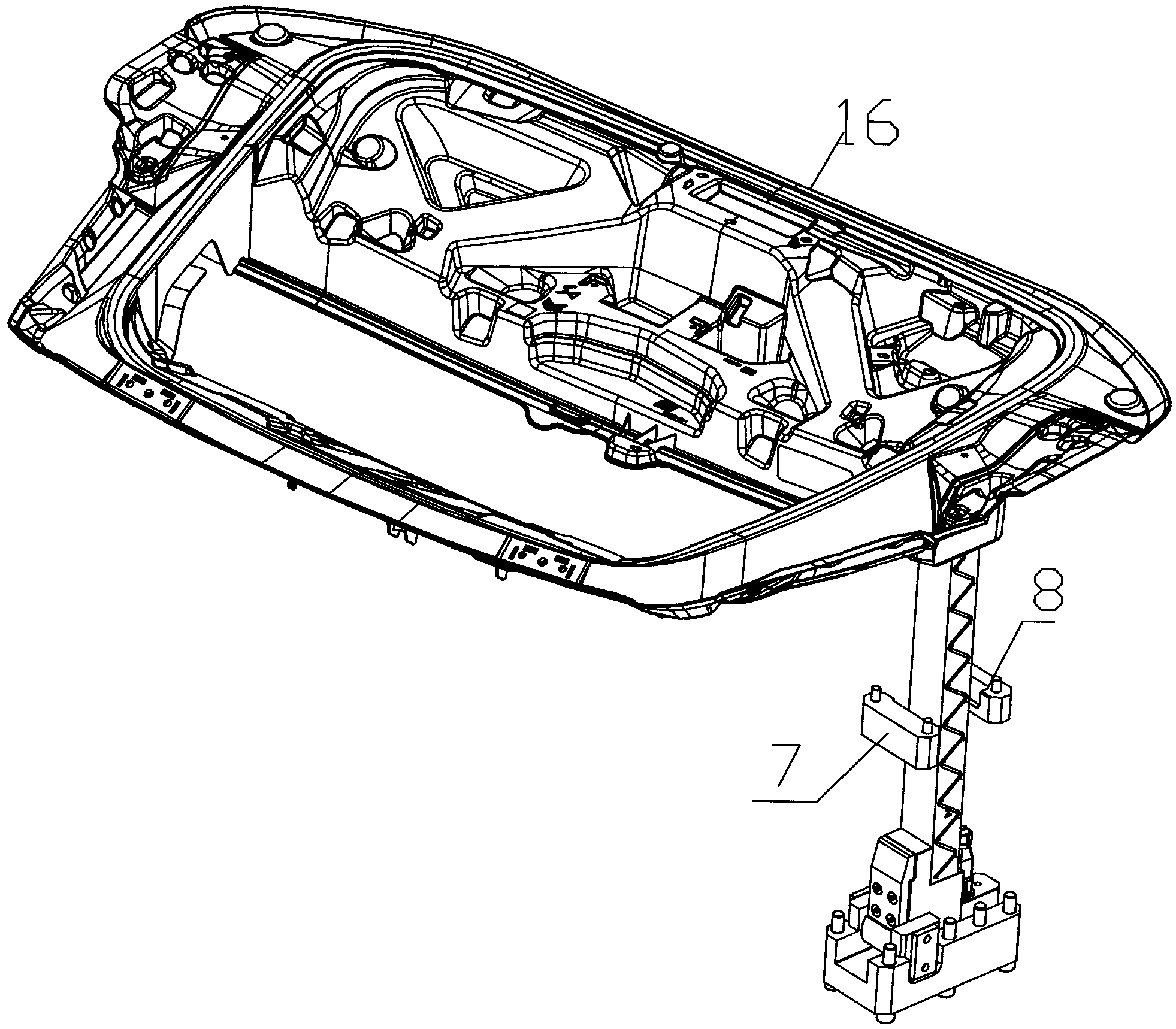

[0023] refer to Figure 1-Figure 9 As shown, a mold for molding SMC material products with a heated and turned inclined roof mechanism includes an upper mold, a lower mold and an inclined roof mechanism. The inclined top consists of two parts, the inclined top head 1 is used to form the product structure, the inclined top head 1 is placed in the mold core and vertically slides with the lower mold core, and the end of the inclined ejector rod part 2 is provided with a rotating mechanism , the inclined roof mechanism also includes a guide assembly that drives the inclined roof to rotate when the inclined roof moves upward.

[0024] The rotating mechanism at the rear end of the slanting rod part 2 includes a slanting top fixed block 3 and a slanted top sliding seat 4, the slanting top fixed block 3 is hingedly installed in the chute of the slanting top sliding seat 4 through a pin shaft 5, and the slanting top fixed block 3 It can rotate around the pin shaft 5, the tail end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com