Test device and test method for three-dimensional static rigidness of tail end of machine tool

A testing device, static stiffness technology, applied in measuring/indicating equipment, metal processing machinery parts, metal processing equipment, etc., can solve the problems of small applied load, complex loading mechanism, easy damage of rigid connection, etc., and achieve smooth force application process. , The effect of high force transmission efficiency and cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

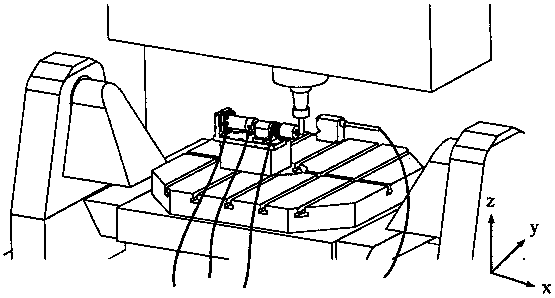

[0059] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, which are only used to explain the application of the device on a certain type of five-axis numerical control machine tool, and are not limiting.

[0060] see figure 1 and figure 2 , a schematic structural diagram of a test device for three-dimensional static stiffness of a machine tool end provided by the present invention. The test device includes a power device 1 , a force transmission device 2 , a control device 3 and a displacement measurement device 4 . The power device 1 is a hydraulic power device, including a hydraulic cylinder 12 and a piston 13 . The power unit 1 also includes hydraulic components familiar to those skilled in the art, such as an oil cylinder, a hydraulic pump, a filter, an overflow valve, and an accumulator, in order to meet the hydraulic power requirements. The force transmission device adopts a cylindrical linear guide rai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com