Apparatus for processing plastic material

A technology of synthetic materials and waste materials, applied in the direction of mixers, plastic recycling, transportation and packaging, etc., can solve the problems of damaged passing rate, poor feeding behavior, narrowed cross-section, etc., to reduce the risk of filling, The effect of reducing the charging pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In the figures, neither the container nor the auger or the mixing tool is shown to scale, nor are they in proportion to each other. For example, in reality the container is often larger than shown here, or the screw is longer than shown here.

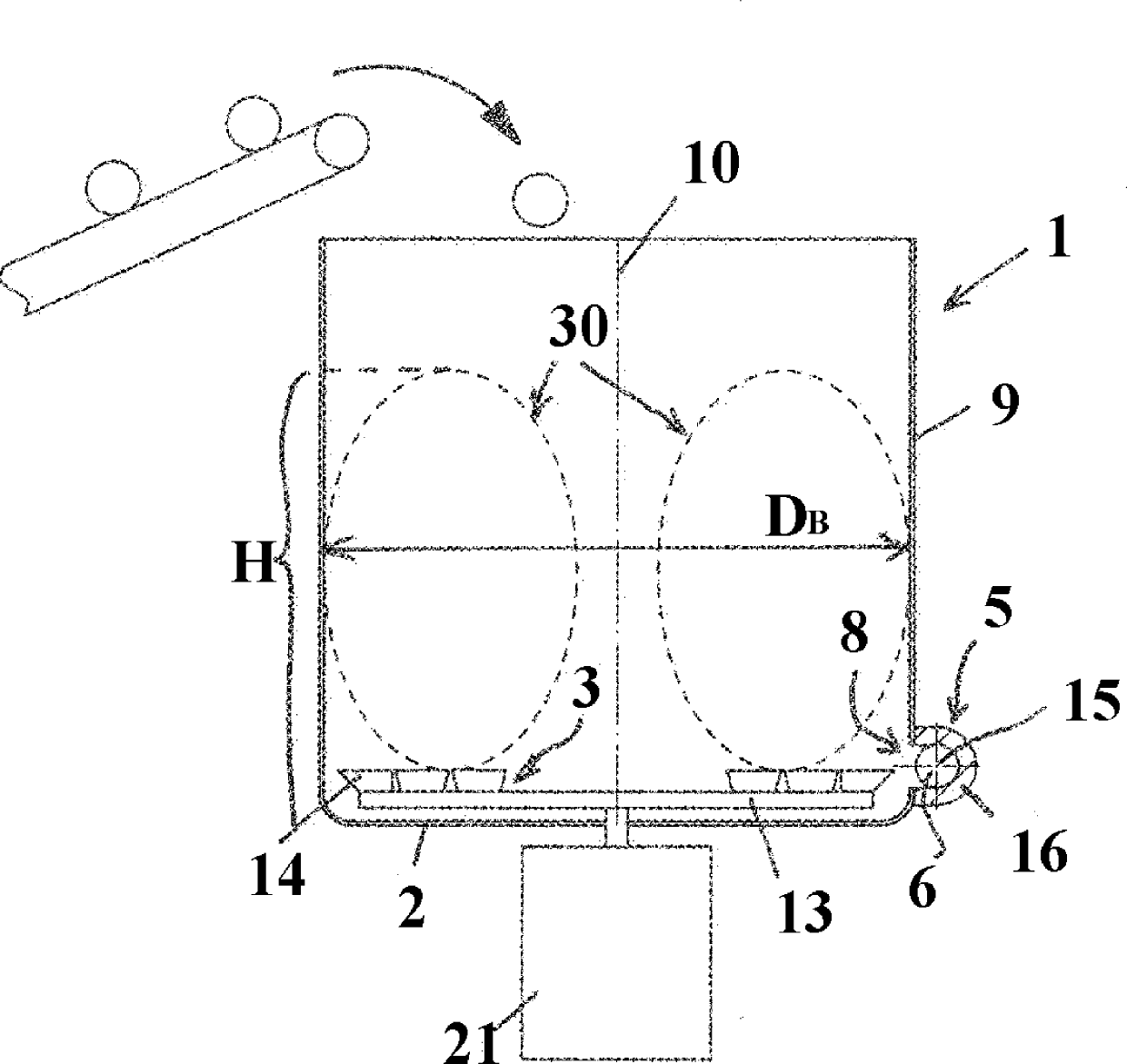

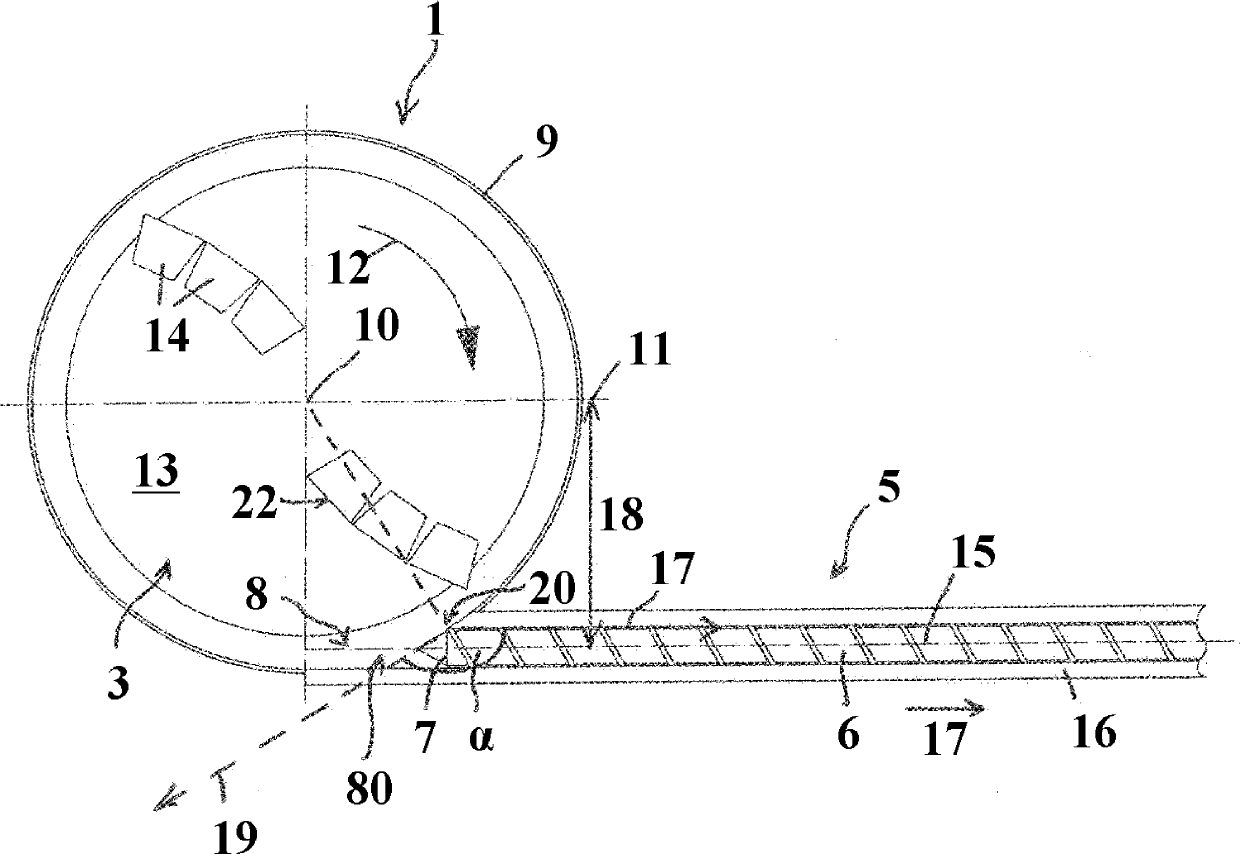

[0075] exist figure 1 with figure 2 The advantageous cutting compressor-extruder-combination for the production or recycling of synthetic materials shown in has a cylindrical container or cutting compressor or shredder 1 with a flat, horizontal bottom surface 2 and a vertical cylindrical enclosure-shaped side wall 9 oriented normal thereto.

[0076] In the case of a small distance from the bottom surface 2, a maximum of about 10 to 20% or less of the height of the side wall 9 - measured from the bottom surface 2 up to the uppermost edge of the side wall 9 -, an orientation parallel to the bottom surface 2 is provided A flat support piece or a tool holder 13 is provided, which can be turned around a central axis of rotation 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com