Shielding structure of electronic equipment

A technology of electronic equipment and shielding structure, applied in the fields of magnetic field/electric field shielding, electrography, electrical components, etc., can solve the problems of difficulty in forming connection parts, increase in cost of wiring substrates, and increase in cost, so as to improve assembly workability, The effect of improving the freedom of wiring and reducing the cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

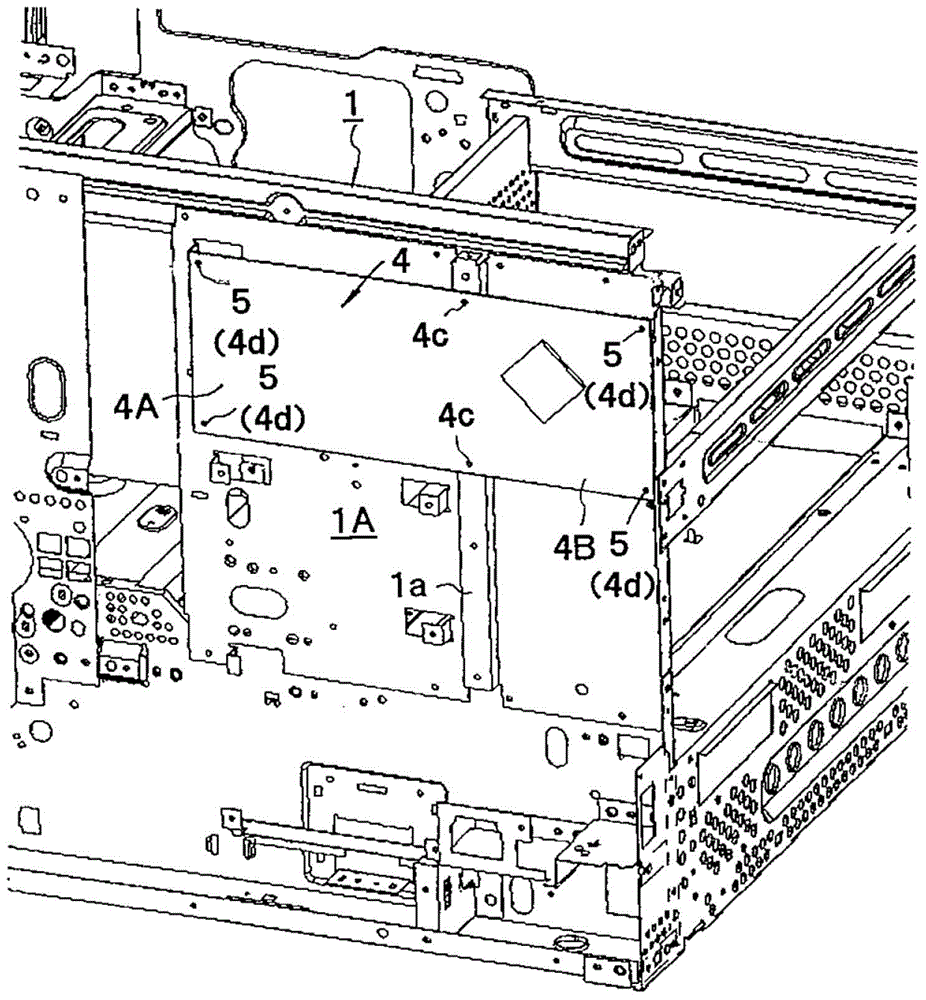

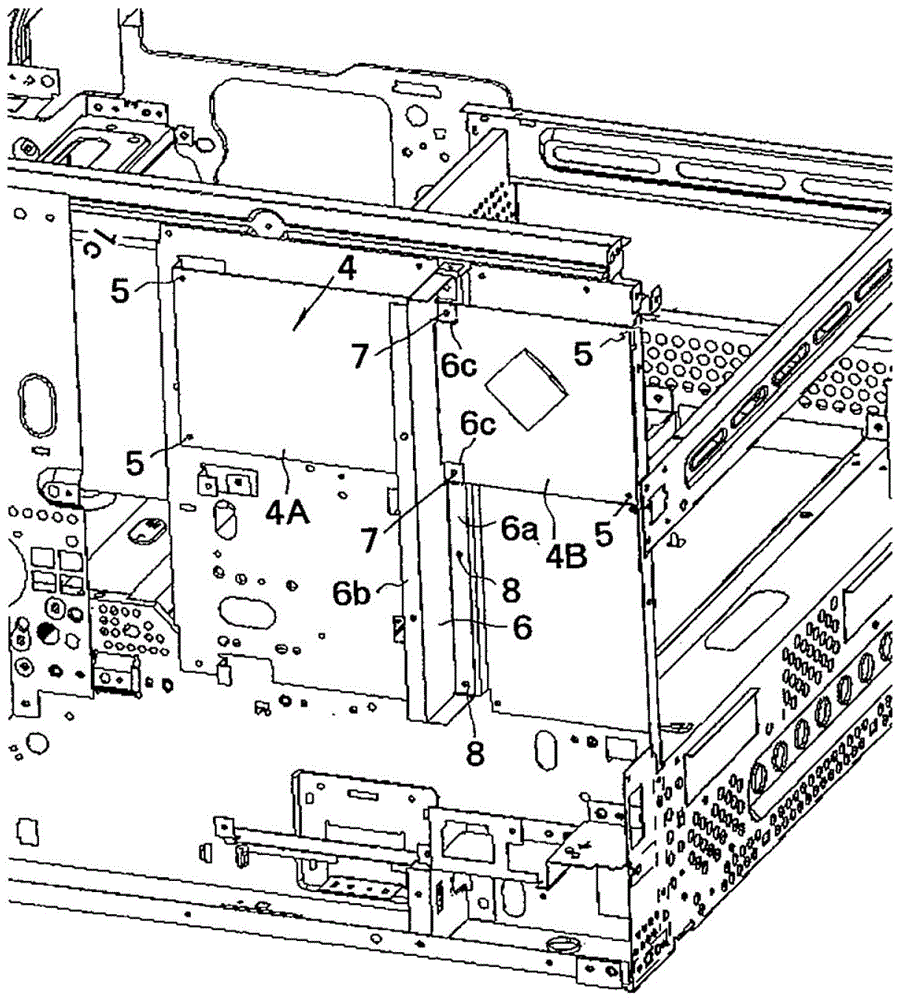

[0021] Embodiments of the present invention will be described below with reference to the drawings.

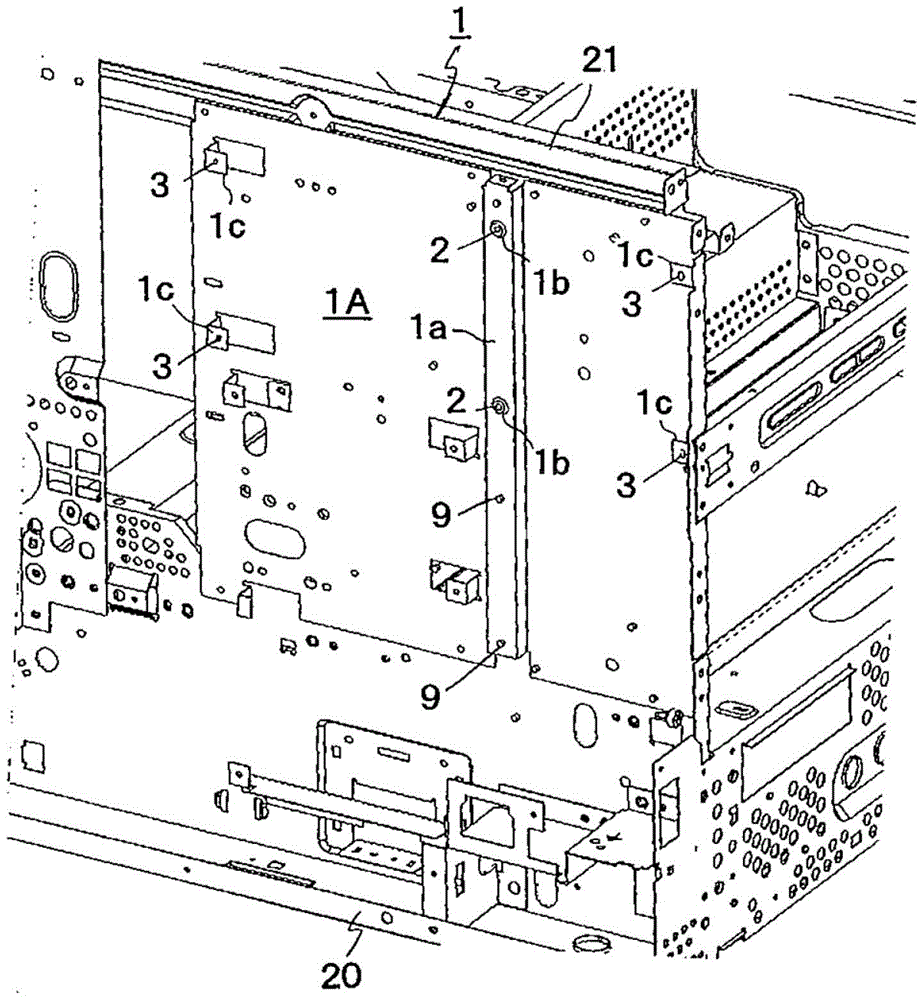

[0022] Such as figure 1 As shown, the main body of an image forming apparatus such as a copying machine according to this embodiment includes a main body frame (casing) 1 formed of a rectangular frame shape by a metal plate. A flat substrate mounting surface 1A is formed on one side (for example, the back surface) of the main body frame 1 . Further, on the substrate mounting surface 1A, a convex portion 1 a having a U-shaped cross section formed by bending a metal plate is integrally formed in the vertical direction. Protrusions 1b are integrally formed at the upper and lower portions of the upper half of the protrusion 1a. A screw hole 2 is formed in the center of each protrusion 1b.

[0023] On the left and right ends of the upper half of the substrate mounting portion 1A of the main body frame 1 divided by the convex portion 1a, L-shaped curved mounting supports 1c are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com