Welding supporting plate for printed circuit boards

A technology for printed circuit boards and pallets, applied in the field of electronic assembly, can solve problems such as clamping, and achieve the effects of improving production efficiency, convenient operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

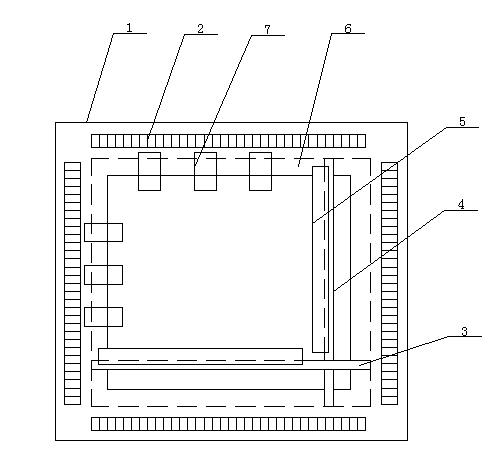

[0011] refer to figure 1 , the specific implementation adopts the following technical solutions: it includes a support frame 1, an adjustment scale 2, a lateral support beam 3, a longitudinal support beam 4, a fixed compression device 5, a track 6 and a movable compression device 7; Adjustment scales 2 are provided on the four sides, and several movable pressing devices 7 are provided on the inner side of the upper frame of the support frame 1 and the inner side of the left frame. The track 6 is movably connected with the support frame 1, and the horizontal support beam 3 and the longitudinal support beam 4 are both provided with fixed pressing devices 5.

[0012] The horizontal support beam 3 and the longitudinal support beam 4 can adjust the distance between them and the movable pressing device 7 through the track 6 according to the actual operation conditions, so as to meet the requirements of circuit boards of different specifications.

[0013] The fixing and pressing dev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com