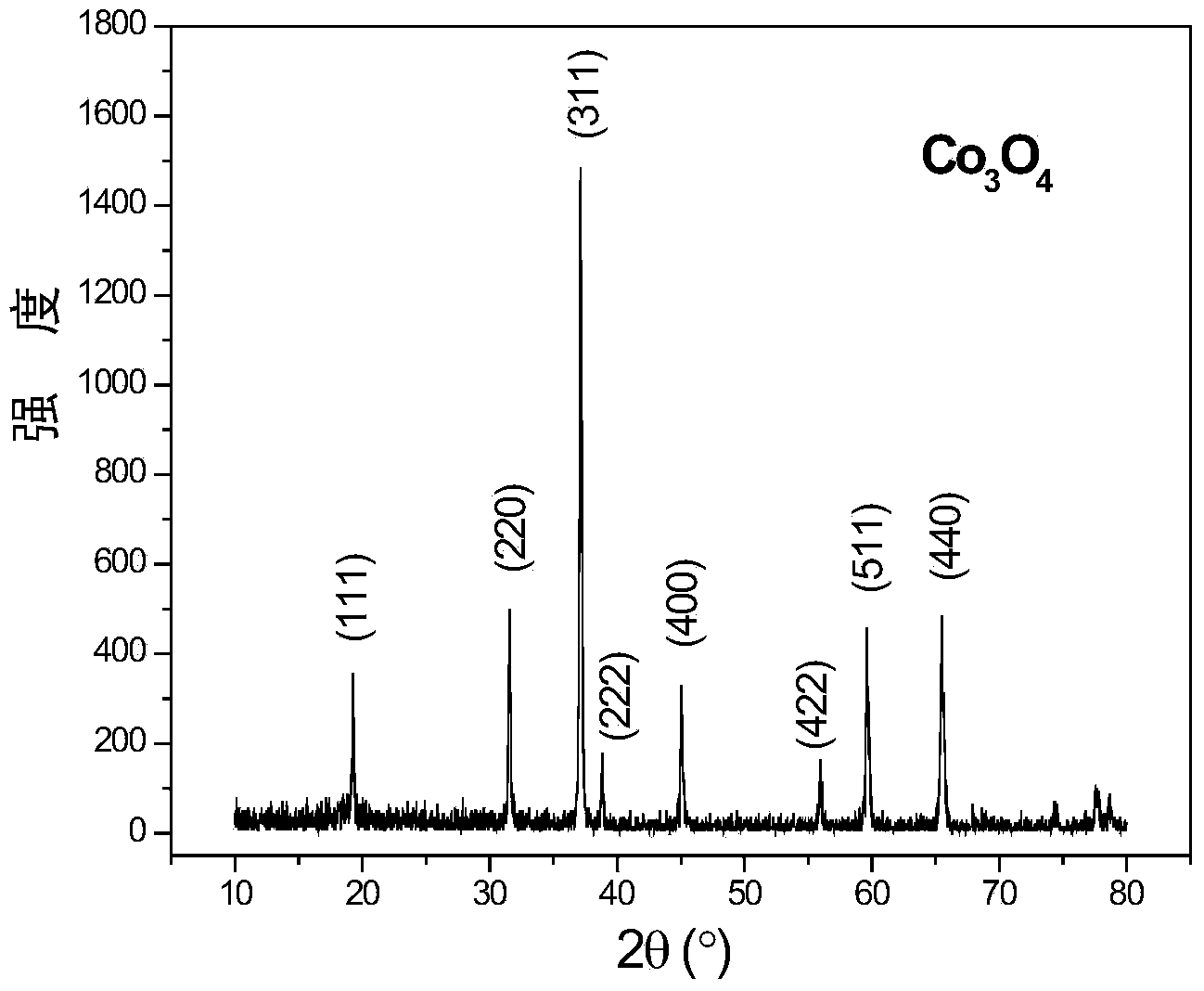

Preparation method of cobaltosic oxide with high-magnification-performance micro-nano structure

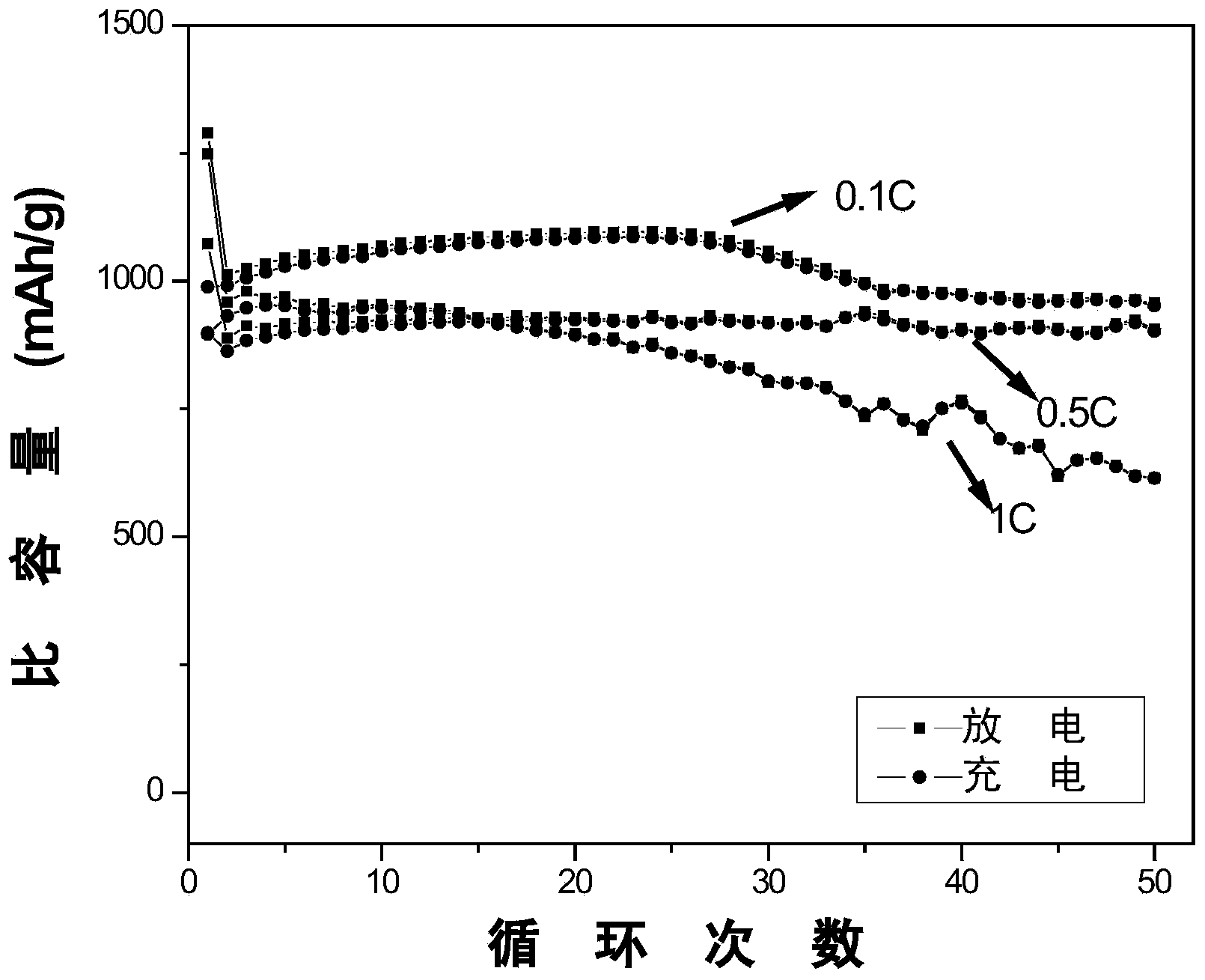

A micro-nano structure, cobalt tetroxide technology, applied in cobalt oxide/cobalt hydroxide, structural parts, electrochemical generators, etc., can solve the problems of restricting industrial application, low capacity retention, poor rate performance, etc. Active point, shorten the diffusion distance, and facilitate the effect of wetting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

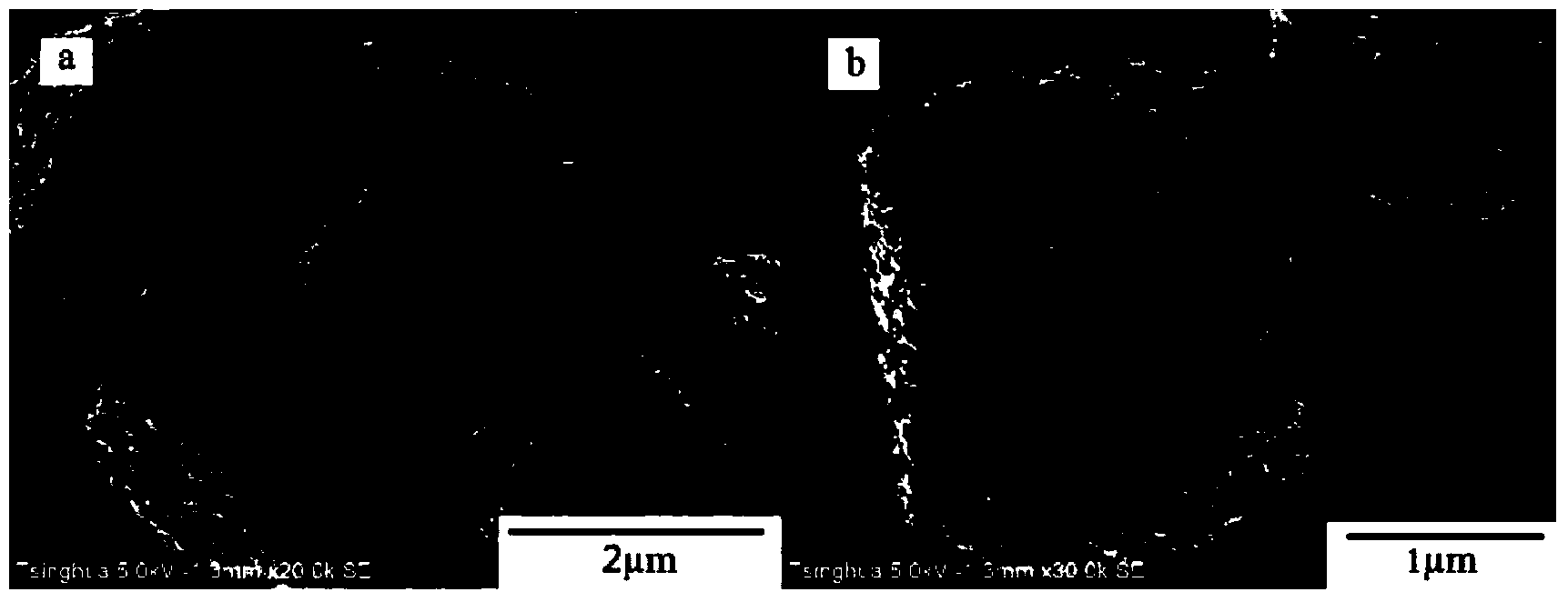

Embodiment 1

[0030] Weigh 2.50g of cobalt acetate tetrahydrate, 3.0g of urea and 3.0g of triethanolamine, dissolve the above substances in deionized water at room temperature, and form a red transparent solution of 100ml at constant volume; Put the reaction kettle into a homogeneous reactor, set the reaction temperature to 160°C, and the reaction time to 12 hours. After the reaction was completed and the reactor was cooled to room temperature, the solid-liquid mixture in the reactor was transferred to a beaker. After repeated washing and centrifugation, the solid was dried in a vacuum oven at 60 °C for 12 hours to obtain a pure pink cobalt carbonate precursor. Put the cobalt carbonate into a crucible, then place it in a muffle furnace, set the reaction temperature to 600°C, and the reaction time to 10 hours. After calcining, a black tricobalt tetroxide powder material is obtained, and its weight is weighed to be about 1.05g. The average particle size measured by a particle size analyzer i...

Embodiment 2

[0032]Weigh 2.91g of cobalt nitrate hexahydrate, 3.0g of urea and 3.0g of triethanolamine, dissolve the above substances in deionized water at room temperature, and form a red transparent solution of 100ml at constant volume; Put the reaction kettle into a homogeneous reactor, set the reaction temperature to 160°C, and the reaction time to 12 hours. After the reaction was completed and the reactor was cooled to room temperature, the solid-liquid mixture in the reactor was transferred to a beaker. After repeated washing and centrifugation, the solid was dried in a vacuum oven at 60 °C for 12 hours to obtain a pure pink cobalt carbonate precursor. Put the cobalt carbonate into a crucible, then place it in a muffle furnace, set the reaction temperature to 600°C, and the reaction time to 10 hours. After calcining, a black tricobalt tetroxide powder material is obtained, and its weight is weighed to be about 1.00g. The average particle size measured by a particle size analyzer is ...

Embodiment 3

[0034] Weigh 2.40g of cobalt chloride hexahydrate, 3.0g of urea and 3.0g of triethanolamine, dissolve the above-mentioned substances in deionized water at room temperature, and form a red transparent solution of 100ml at constant volume; In a stainless steel reaction kettle made of tetrafluoroethylene, put the reaction kettle into a homogeneous reactor, set the reaction temperature to 140° C., and the reaction time to 12 hours. After the reaction was completed and the reactor was cooled to room temperature, the solid-liquid mixture in the reactor was transferred to a beaker. After repeated washing and centrifugation, the solid was dried in a vacuum oven at 60 °C for 12 hours to obtain a pure pink cobalt carbonate precursor. Put the cobalt carbonate into a crucible, then place it in a muffle furnace, set the reaction temperature to 550°C, and the reaction time to 10 hours. After calcining, black tricobalt tetroxide powder material is obtained, and its weight is weighed to be ab...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com