Method for rapidly, simply and conveniently extracting volatile flavor substances from fermented grains

A flavor and volatility technology, applied in the field of analysis and detection, can solve the problems of large amount of organic solvent, complicated technical operation, high labor intensity, etc., and achieve the effect of less solvent amount, simple operation process and low labor intensity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] a) Soaking and ultrasonic extraction: take 10g of fermented grains, add 8μl of citronellol internal standard and 40ml of ultrapure water cooled after boiling for 15min, soak for 120min, ultrasonically extract for 30min, and then centrifuge at 10000r / min for 12min to obtain Serum;

[0026] b) Organic solvent extraction: Take 20ml of the supernatant obtained by the above centrifugation, put it in a 50ml test tube with a stopper, add sodium chloride to make the solution saturated; then add 5ml of ether, cover the bottle stopper, shake for 4min, and let it stand for 5min After centrifugation, the organic phase and the aqueous phase are separated, and 2ml of the organic phase is taken for testing;

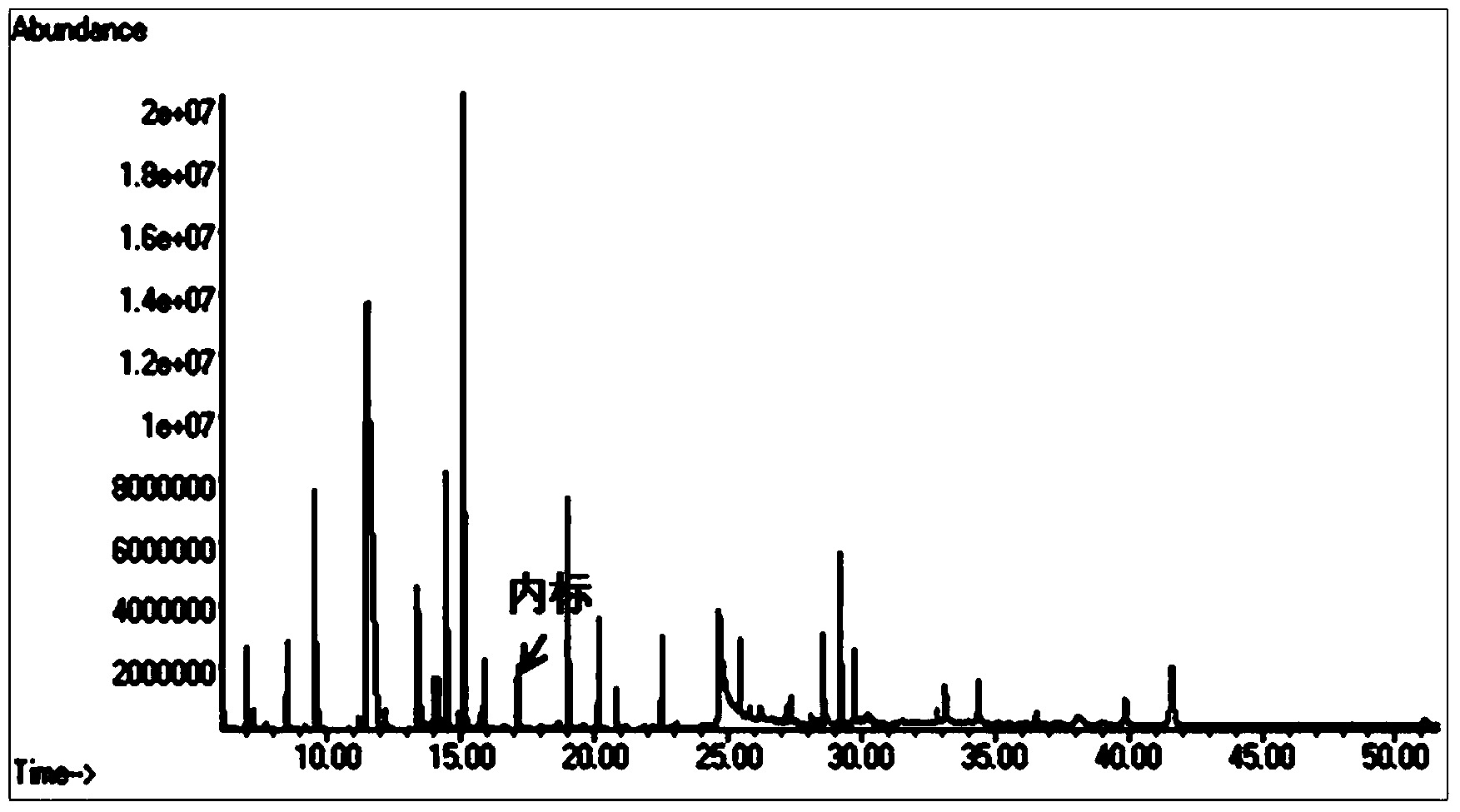

[0027] c) Qualitative and quantitative analysis of volatile flavor substances: the qualitative comparison of standard ion fragments in NIST 08 Databas (Agilent Technologies Inc.) and AMDIS library requires a matching degree greater than 85%; the total ion chromatogram of volatile...

experiment example 2

[0033] a) Soaking and ultrasonic extraction: take 5g of fermented grains, add 10μl of citronellol internal standard and 45ml of ultrapure water cooled after boiling for 20min, soak for 60min, ultrasonically extract for 40min, and centrifuge at 5000r / min for 15min to obtain the supernatant liquid;

[0034] b) Organic solvent extraction: Take 15ml of the supernatant obtained by the above centrifugation, put it in a 50ml test tube with a stopper, add sodium chloride to make the solution saturated; then add 2ml of pentane, cover the bottle stopper, shake for 3min, and let stand Centrifuge after 10 minutes, separate the organic phase and the aqueous phase, and take 1ml of the organic phase for detection;

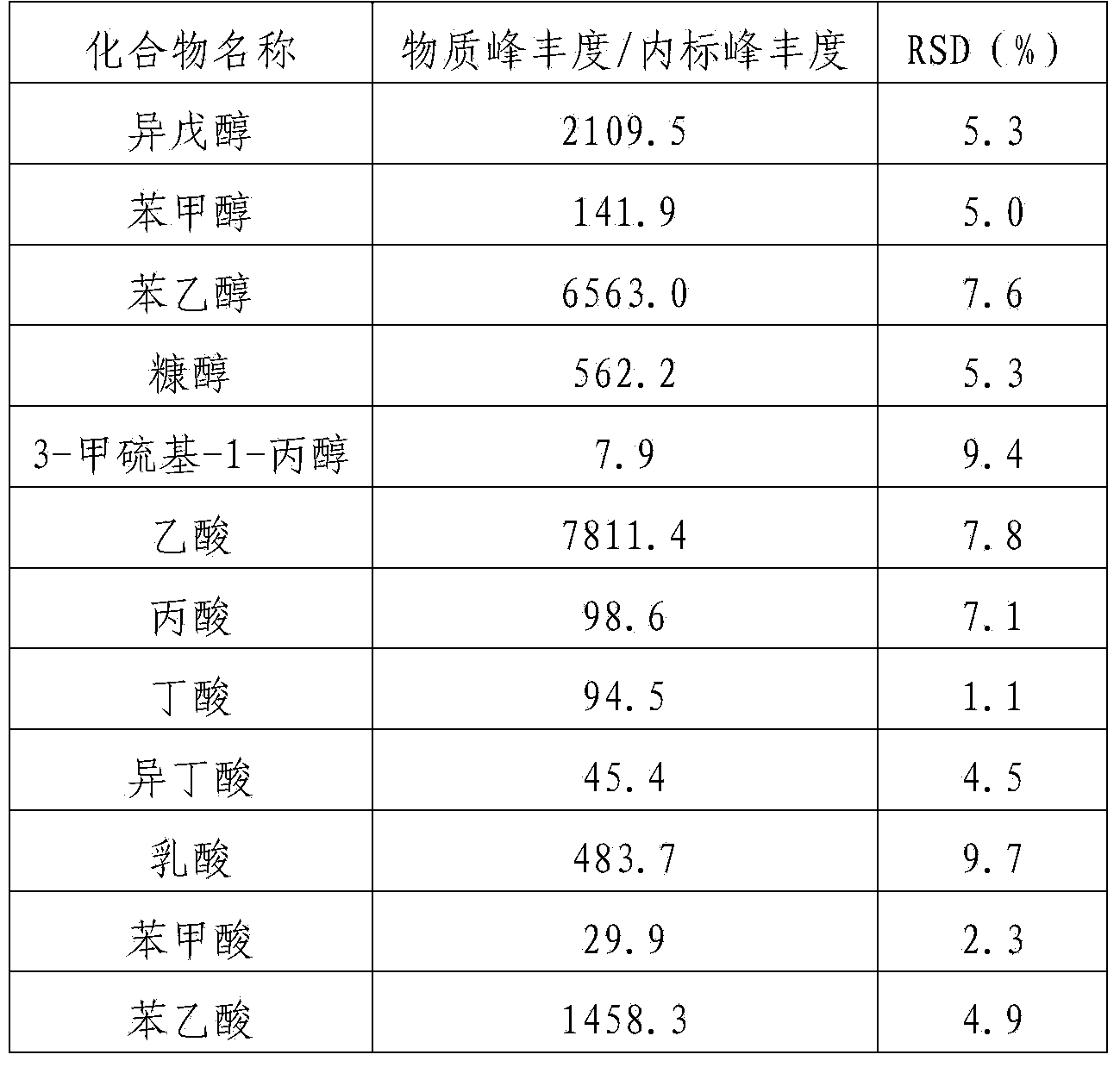

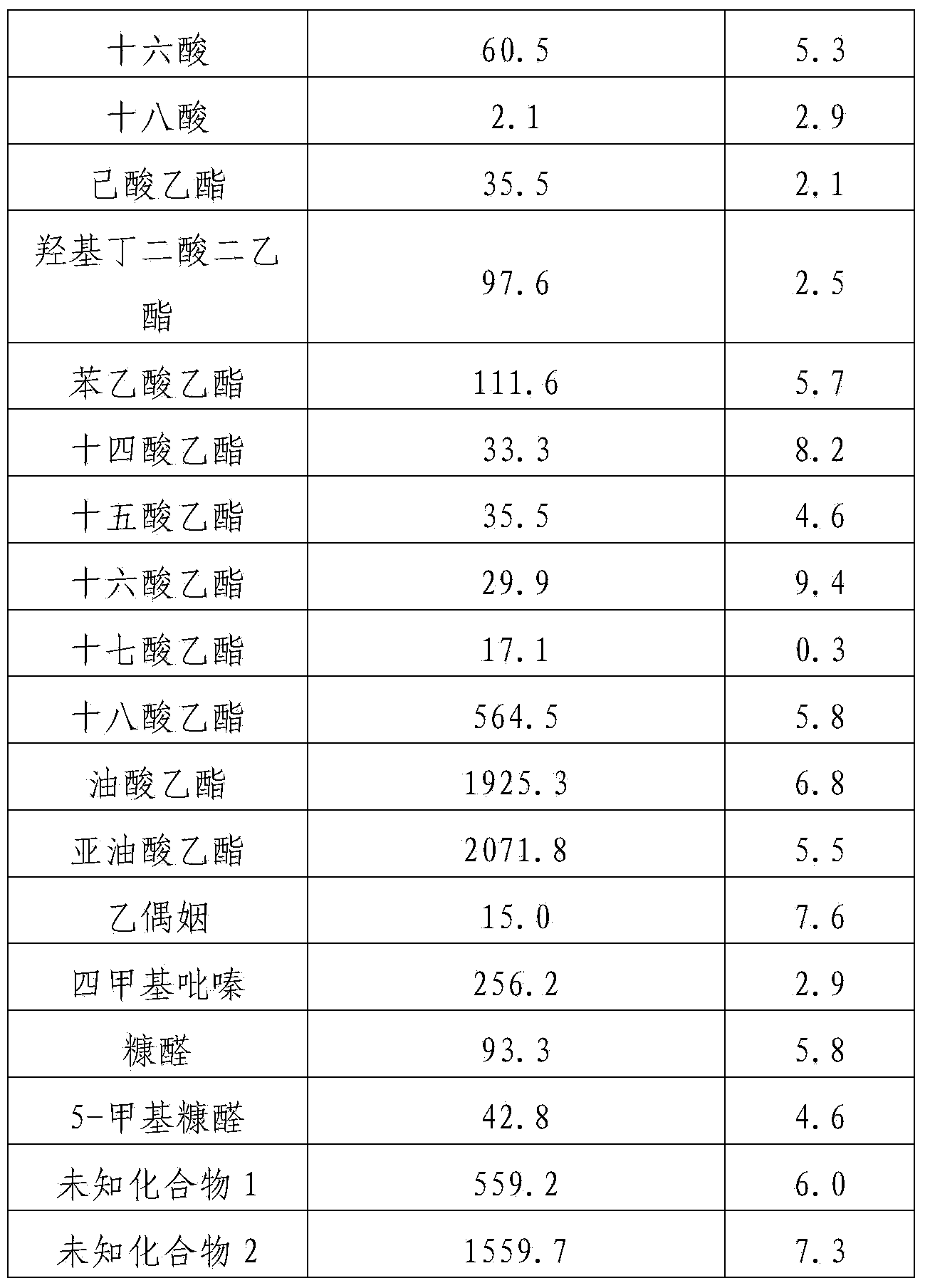

[0035] c) Quantification of volatile flavor substances: using the method described in Example 1, finally calculate the content of each volatile flavor substance, see Table 2. It can be seen from the table that the relative standard deviation (RSD) of each substance is less than ...

experiment example 3

[0040] a) Soaking and ultrasonic extraction: Take 15 g of wine grains, add 5 μl of citronellol internal standard and 35 ml of ultrapure water cooled after boiling for 10 minutes, soak for 150 minutes, ultrasonically extract for 20 minutes, centrifuge at 18000 r / min for 5 minutes to obtain supernatant.

[0041] b) Organic solvent extraction: Take 25ml of the supernatant obtained by the above centrifugation and place it in a 50ml test tube with a stopper, add sodium chloride to make the solution saturated; then add 6ml of a mixture of diethyl ether and pentane with a volume ratio of 1:1 , cover the bottle, shake for 5 minutes, let stand for 8 minutes and then centrifuge, the organic phase and the aqueous phase are separated, and 3ml of the organic phase is taken for testing.

[0042] c) Quantification of volatile flavor substances: using the method described in Example 1, finally calculate the content of each volatile flavor substance, see Table 3. It can be seen from the table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com