Gas turbine temperature measurement

A technology of gas turbine and gas, applied in the direction of gas turbine engine testing, temperature measurement of moving fluid, gas turbine device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] The same or functionally equivalent elements are provided with the same reference numbers below. The examples do not limit the invention to such an arrangement in any way.

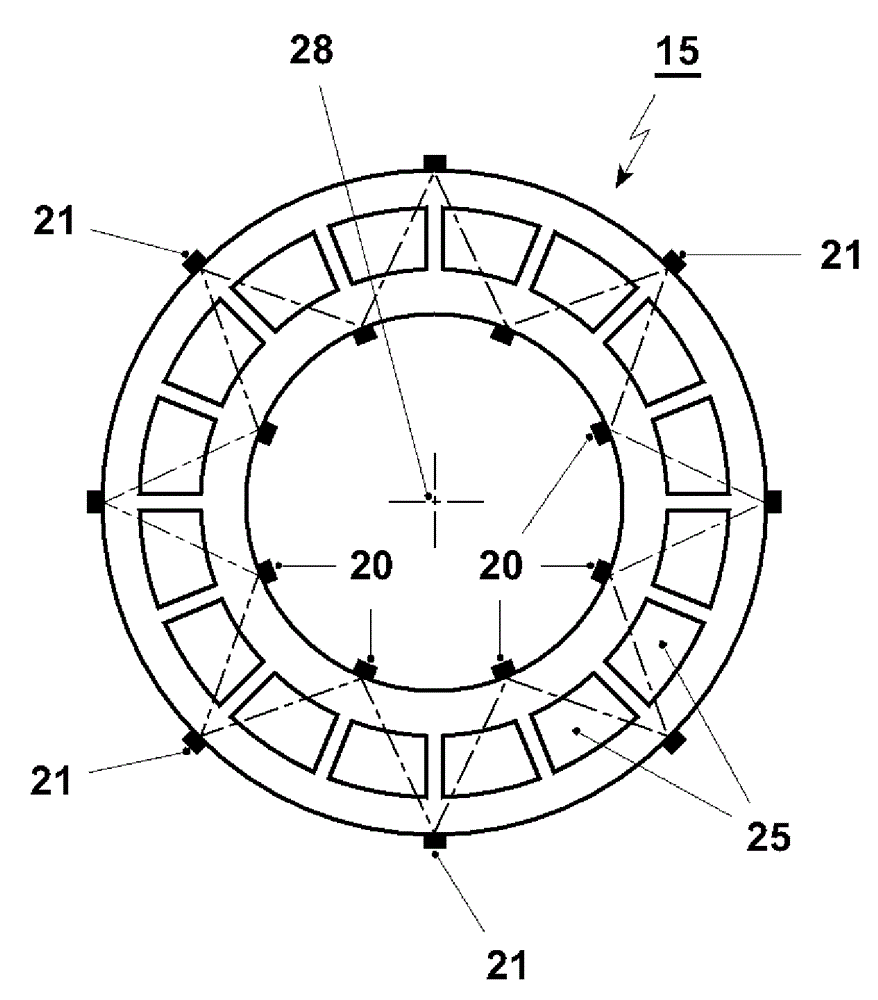

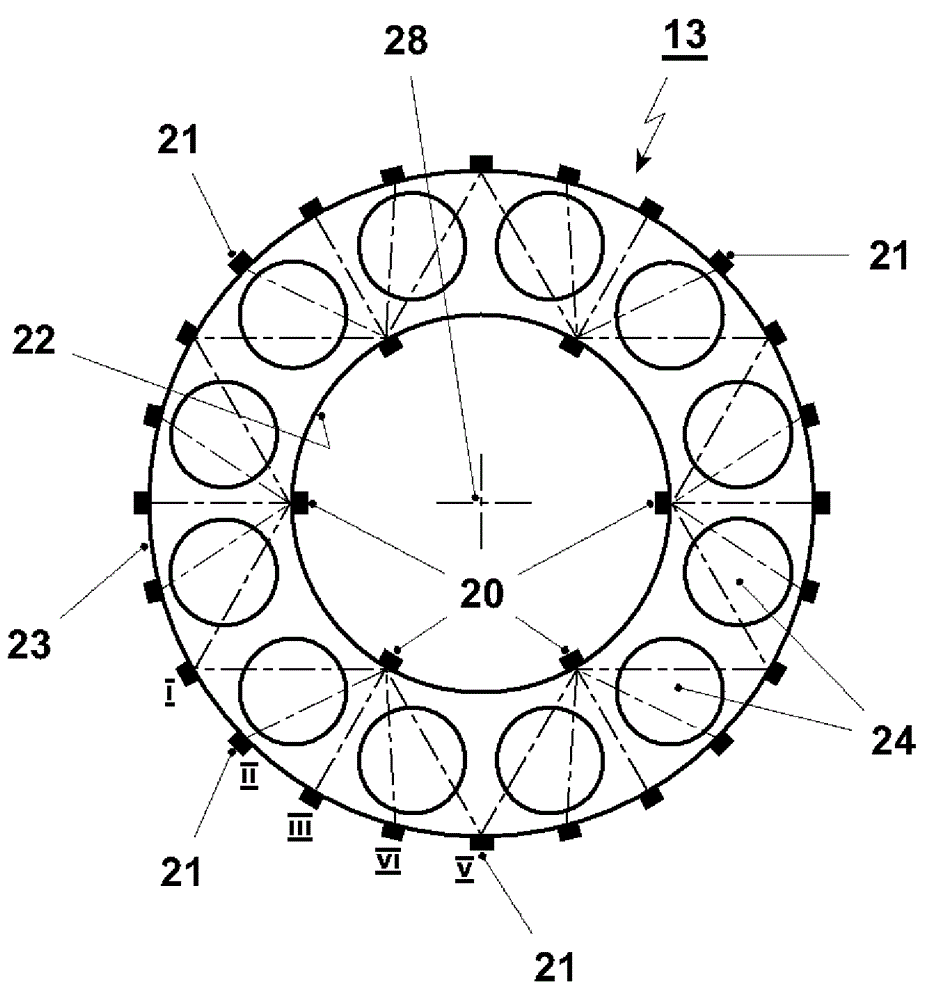

[0110] in figure 1 An exemplary arrangement is shown schematically in. The gas turbine 10 is provided with a compressor inlet gas 11. In the gas turbine 10, the compressor 12 is followed by a first combustor, and the first combustor includes a first burner 24 and a first combustion chamber 13. In the first burner 34, the fuel 37 is added to the compressed gas, and the mixture is burned in the first combustion chamber 13. The hot combustion gases are fed from the first combustion chamber 13 to the first turbine 14. After the first turbine 14 is a second combustor. The second combustor includes a sequential burner 25 (also called a second burner) And the sequential combustion chamber 15 (also called the second combustion chamber). The fuel 37 may be added to the gas leaving the first turbine 14 in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com