Road multi-functional integrated maintenance machine

A multi-functional, road-based technology, applied in the direction of road surface cleaning, chemical instruments and methods, cleaning methods using liquids, etc., can solve problems such as low efficiency, unclean treatment, and peeling off of the protective layer, and achieve convenient maintenance, wide application range, The effect of high work pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

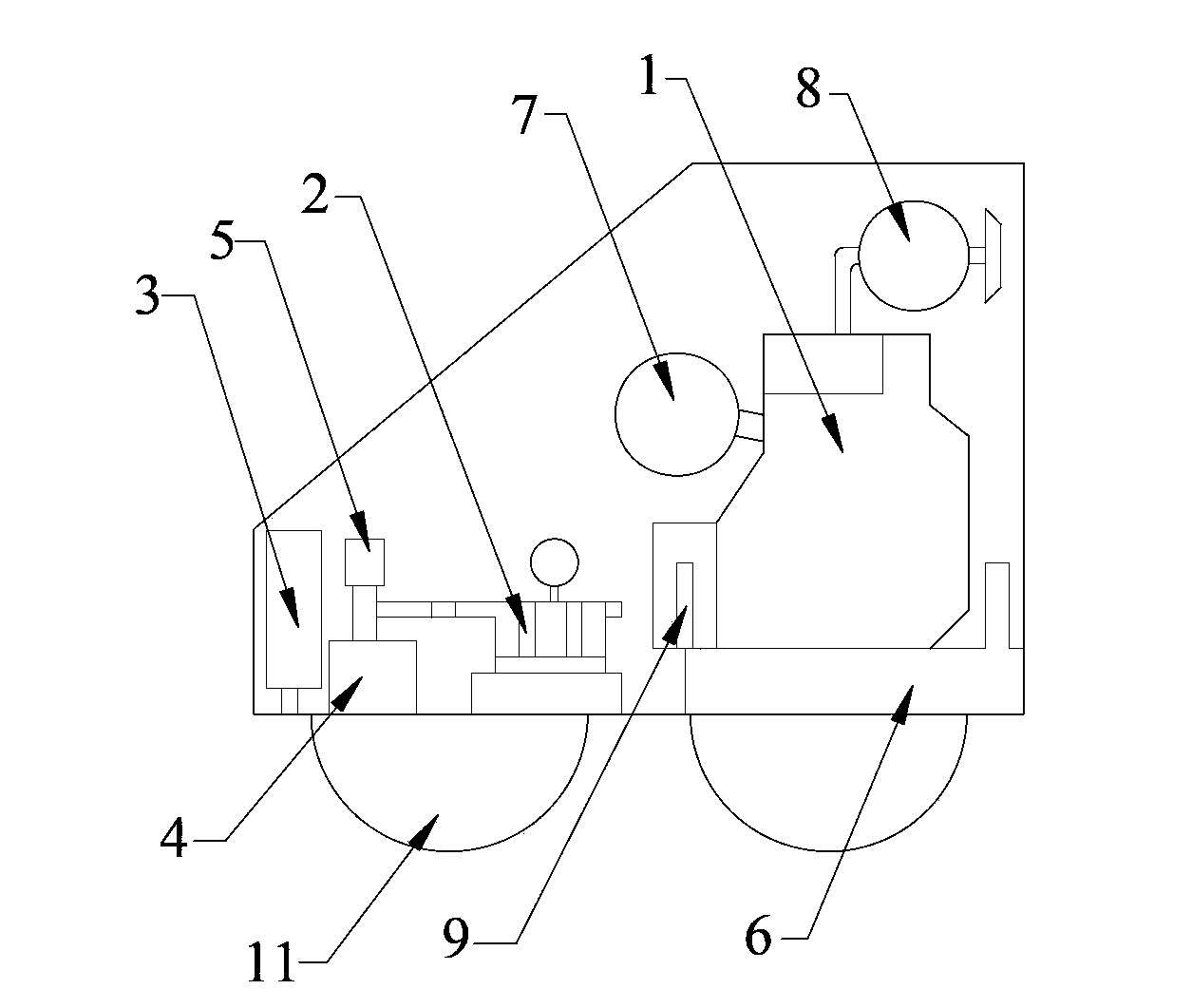

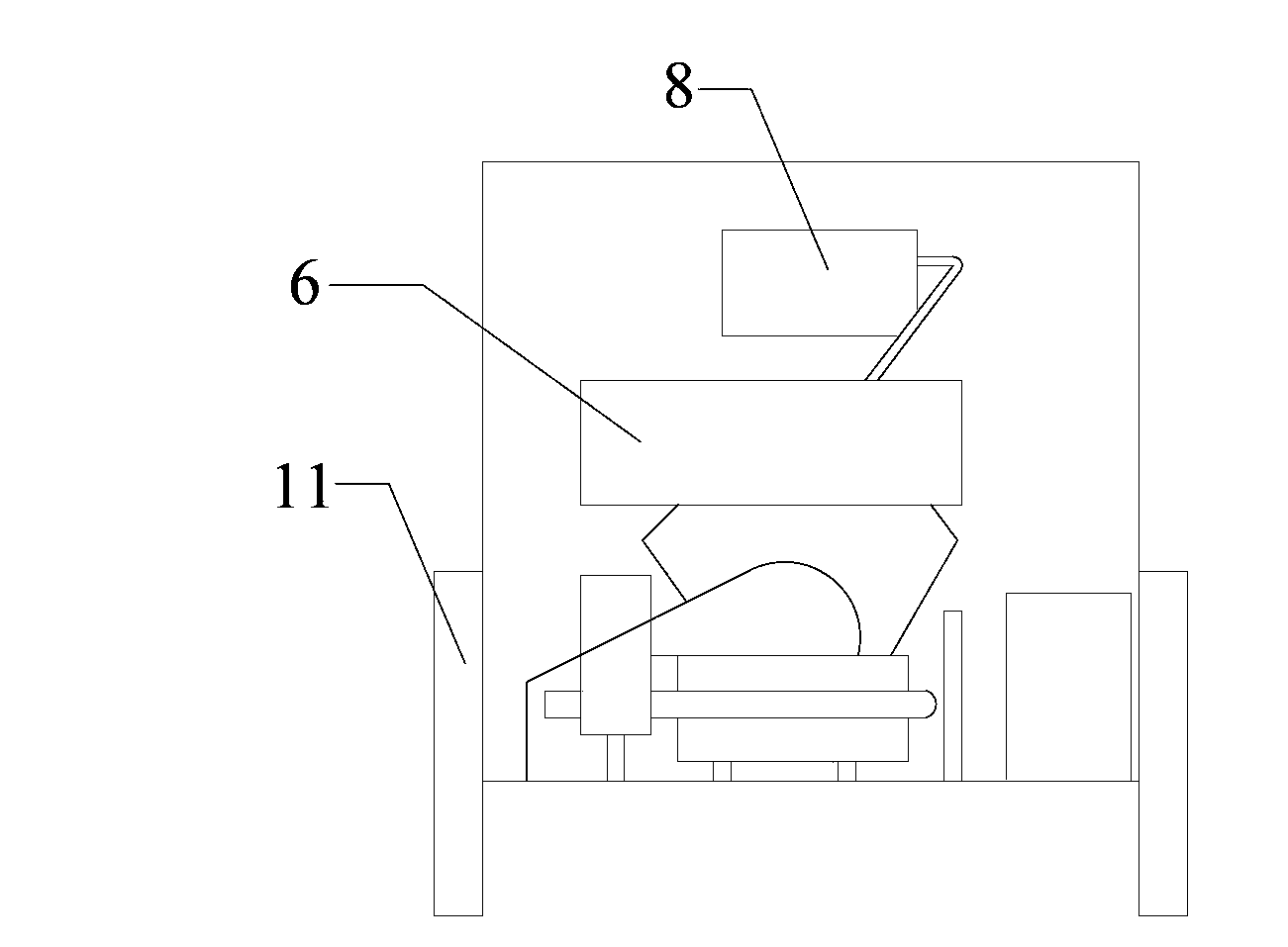

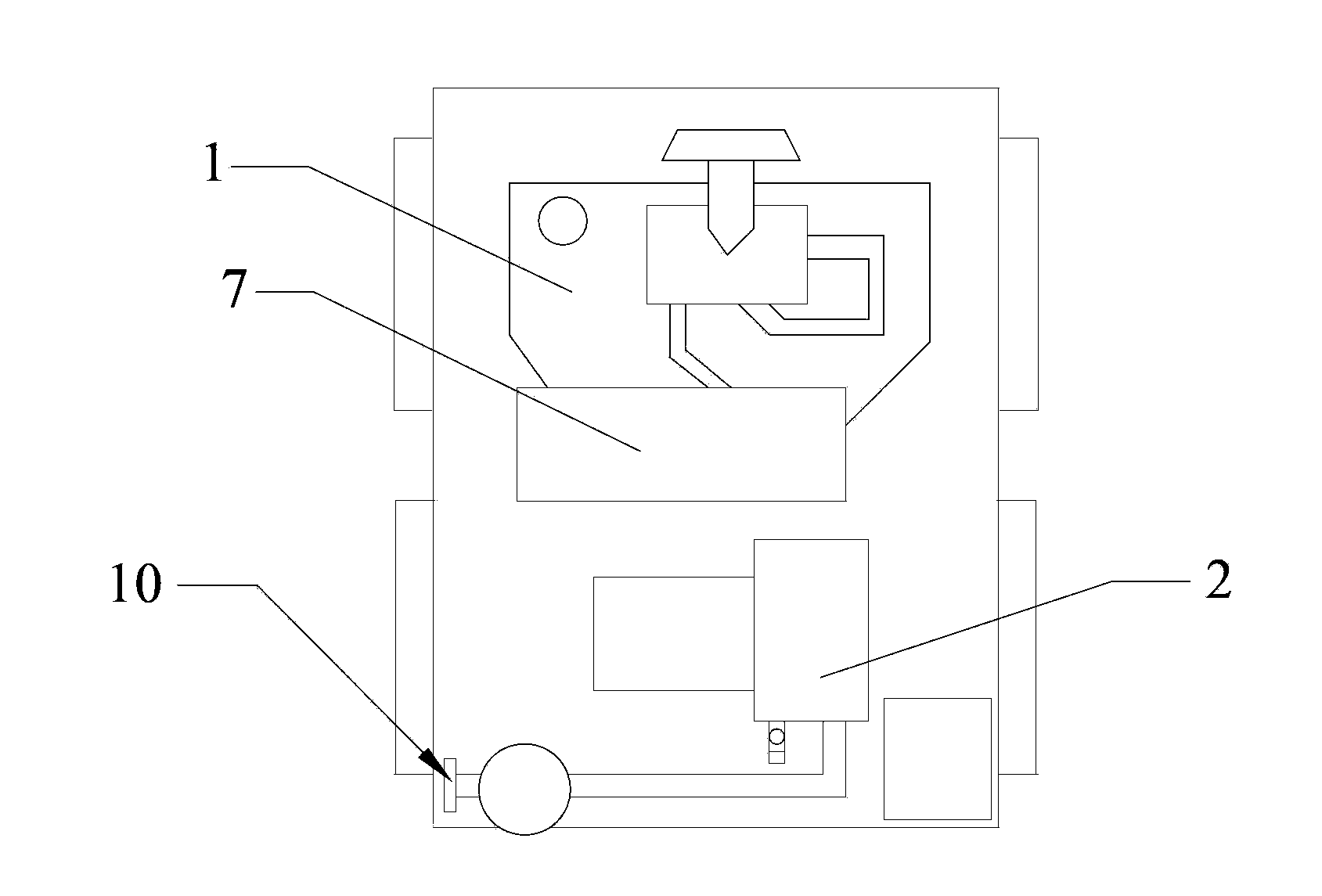

[0042] Road multifunctional integrated maintenance machine, its structure is as follows Figure 1-3 Shown, comprise the gasoline engine 1 that is installed on the car body, high-pressure pump 2, water inlet filter 3, high-pressure water pipe, gun rod, gun head, water inlet filter 3 is located at the front portion of car body, passes water inlet pipe and The high-pressure pump 2 is connected, and the high-pressure pump is also connected with a storage battery 4 . Gasoline engine 1 is located at the rear portion of car body and provides power for high-pressure pump 2, and high-pressure water pipe is connected with high-pressure pump 2, and the end of high-pressure water pipe connects gun rod and gun head.

[0043] The high-pressure pump 2 is connected to the pressure regulating valve through a joint. The surface of the joint is coated with a zinc layer, and there are O-ring flat sealing sections at both ends, and a transition section with an inner cone of 24° in the middle. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com