Anti-demounting nut

An anti-disassembly and nut technology, which is applied in the direction of nuts, bolts, threaded fasteners, etc., can solve the problems of irregular structure of parts and difficulty in disassembly, and achieve the effect of simple structure, reliable anti-disassembly effect and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

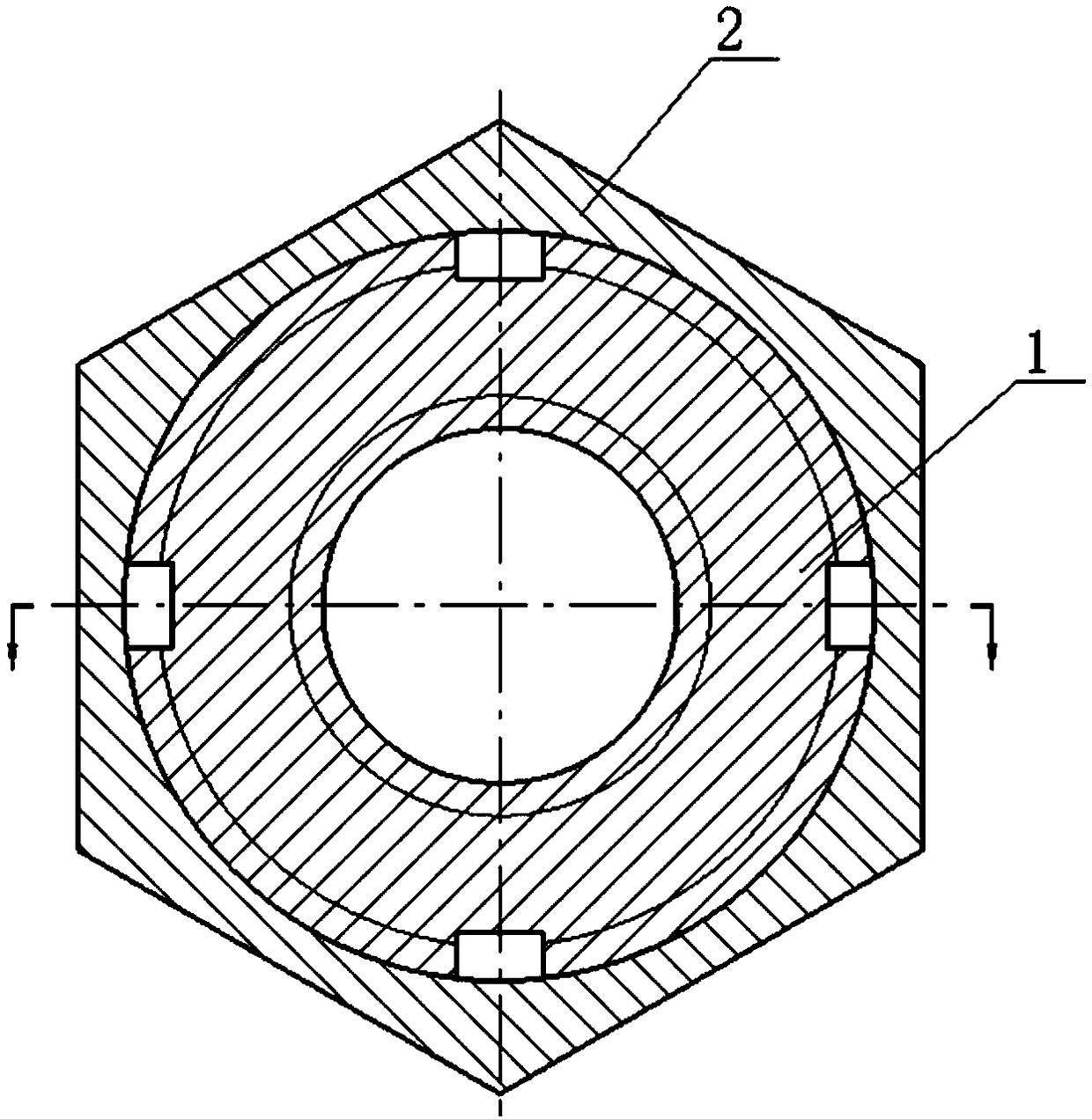

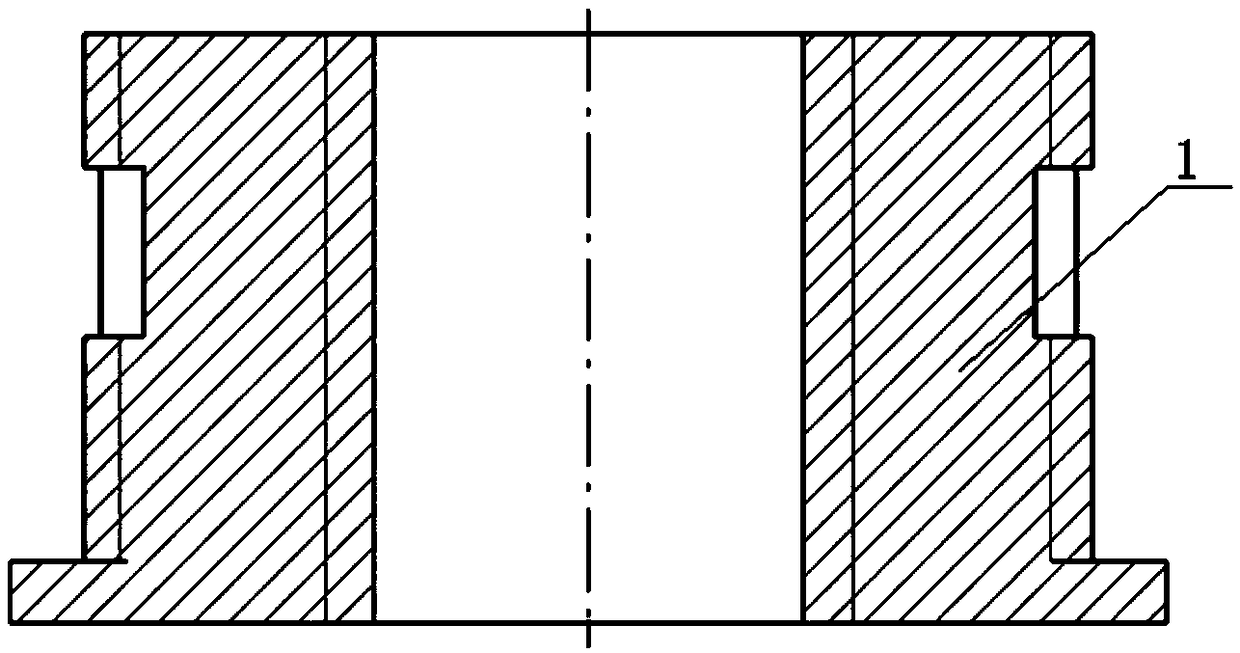

[0019] A kind of anti-dismounting nut of the present invention, as figure 1 As shown, including nut base 1 and nut 2;

[0020] Such as figure 2 As shown, the nut base 1 is a cylindrical piece with openings at both ends. The inner and outer walls of the nut base 1 are respectively processed with internal threads and external threads with the same direction of rotation. The bit platform is processed with a wrench groove on the outer wall of the nut base 1;

[0021] The nut 2 is a ring whose length matches the length of the nut base 1. The inner wall of the nut 2 is processed with an internal thread matching the outer thread of the nut base 1. The outer wall of the nut 2 is a hexagonal cylindrical surface; the nut 2 is threaded Screw into the outer wall of the nut base 1 until the front end of the nut 2 tightens the annular limiter at the locking end of the nut base 1; the tightness of the screw connection between the nut 2 and the nut base 1 is less than that of the nut base ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com