Full-fogging-surface flexible cable composite material and preparation method thereof

A flexible cable and composite material technology, applied in the direction of plastic/resin/wax insulators, organic insulators, etc., can solve problems such as melt fracture, wrinkled wire surface, easy detachment, etc., to achieve energy saving, high water resistance, optimization The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

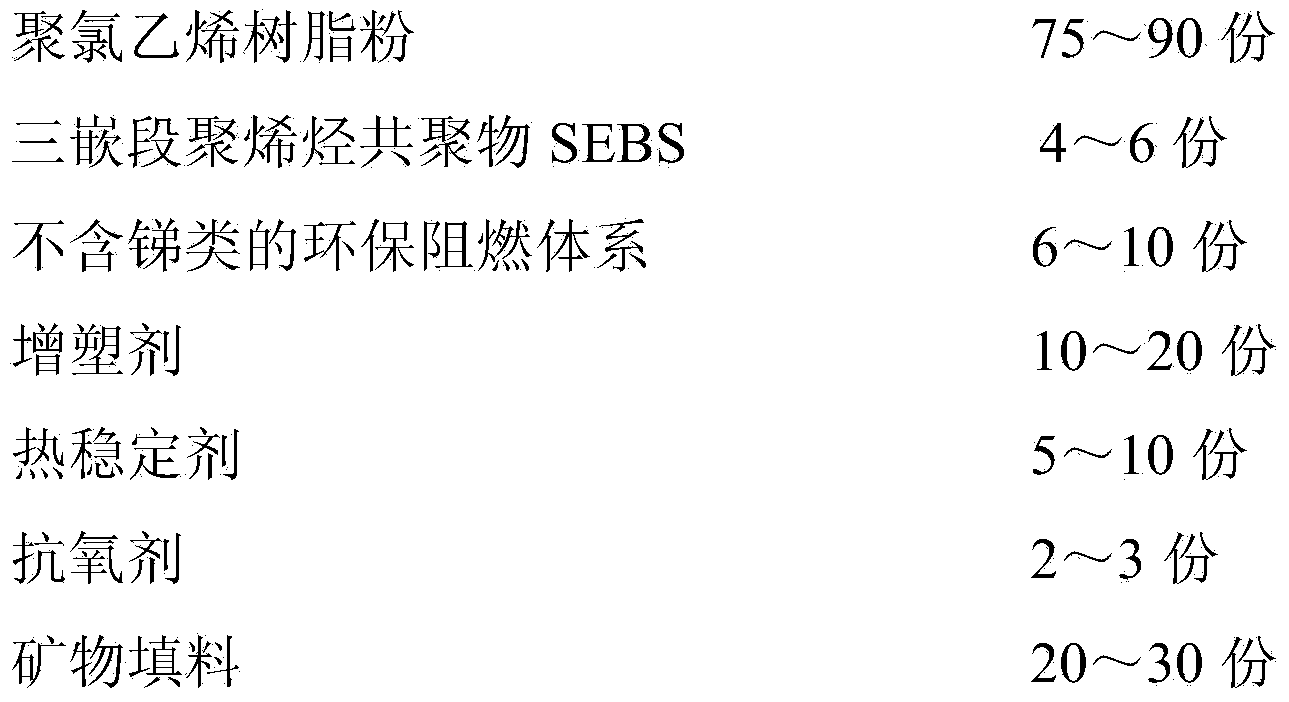

[0051] see figure 1 , the present invention provides a full matte flexible cable composite material, which is made of the following raw materials in parts by weight:

[0052]

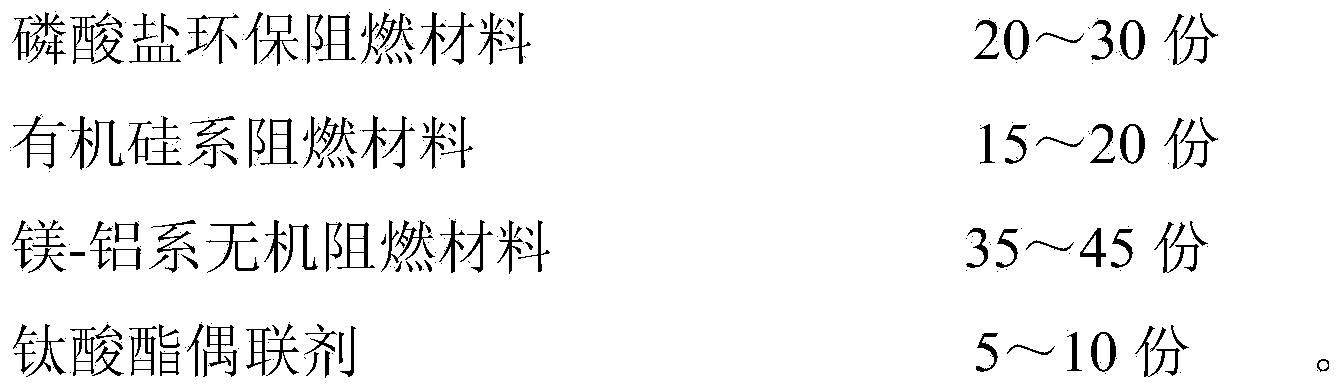

[0053] The antimony-free environment-friendly flame retardant system is made of the following raw materials in parts by weight:

[0054]

[0055] The polyvinyl chloride resin powder has a molecular weight of 1000-1800, a K value of 60-80, and a polymerization degree of 1200-1500.

[0056] Said three-block polyolefin copolymer SEBS, polyvinyl chloride resin powder, antimony-free environment-friendly flame retardant system, plasticizer, heat stabilizer, antioxidant, mineral filler, through melt blending Modification of polyvinyl chloride resin powder.

[0057] The three-block polyolefin copolymer SEBS is a three-block polyolefin copolymer SEBS after oil-extending treatment, and the mass ratio of SEBS to white oil is: SEBS:white oil=1.5:3 for oil-extending deal with.

[0058] Described plasticize...

Embodiment 2

[0085] The steps of the fully matte flexible cable composite material and its preparation method provided in this example are basically the same as those in Example 1, except that:

[0086] A fully matte flexible cable composite material, which is made of the following raw materials in parts by weight:

[0087]

[0088] The antimony-free environment-friendly flame retardant system is made of the following raw materials in parts by weight:

[0089]

[0090] The polyvinyl chloride resin powder has a molecular weight of 1300, a K value of 70, and a degree of polymerization of 1350.

[0091] The plasticizer is trioctyl trimellitate;

[0092] Described thermal stabilizer, it is tribasic lead sulfate;

[0093] Described antioxidant, it is 2.4 di-tert-butylphenyl-phosphite triesters;

[0094] The mineral filler is magnesium hydroxide.

[0095] A preparation method for preparing the above-mentioned fully matte flexible cable composite material, which specifically includes th...

Embodiment 3

[0116] The steps of the fully matte flexible cable composite material and its preparation method provided in this example are basically the same as those in Examples 1 and 2, except that:

[0117] A fully matte flexible cable composite material, which is made of the following raw materials in parts by weight:

[0118]

[0119] The antimony-free environment-friendly flame retardant system is made of the following raw materials in parts by weight:

[0120]

[0121] The polyvinyl chloride resin powder has a molecular weight of 1800, a K value of 60, and a degree of polymerization of 1500.

[0122] Described plasticizer, it is epoxidized soybean oil;

[0123] Described heat stabilizer, it is the combination in tribasic lead sulfate, dibasic lead phosphite, calcium stearate;

[0124] Described antioxidant, it is the combination in 2.4 di-tert-butylphenyl-phosphite triesters, dilauryl thiodipropionate, distearyl thiodipropionate;

[0125] The mineral filler is a combination...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com