Automatic glass loading machine

A glass machine and automatic technology, applied in the field of instruments, can solve problems such as low efficiency, inconvenient material retrieving, and high labor intensity of workers, and achieve the effect of simple overall structure, simple structure, and novel design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

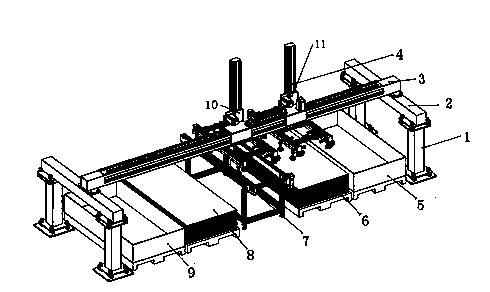

[0011] refer to figure 1 As shown, the automatic glazing machine is characterized in that it includes four frame columns 1, two frame beams 2 are arranged on the upper ends of the frame columns 1, and the two frame beams 2 are connected by a moving beam 3. A receiving glass conveying line 7 is arranged in the middle of the bottom ends of the four frame columns 1, a first glass trestle 6 and a second glass trestle 8 are arranged on both sides of the receiving glass conveying line 7, and the other end of the first glass trestle 6 is provided with The first waste paper box 5, the other end of the second glass trestle 8 is provided with a second waste paper box 9, and the upper end of the moving crossbeam 3 is provided with two mobile work shafts 4, and the two mobile work shafts are respectively provided with A first gripping and trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com