Double disc round sander

A circular sand machine and chassis technology, applied in the field of grinding tools, can solve the problems of complex assembly process and many heat sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

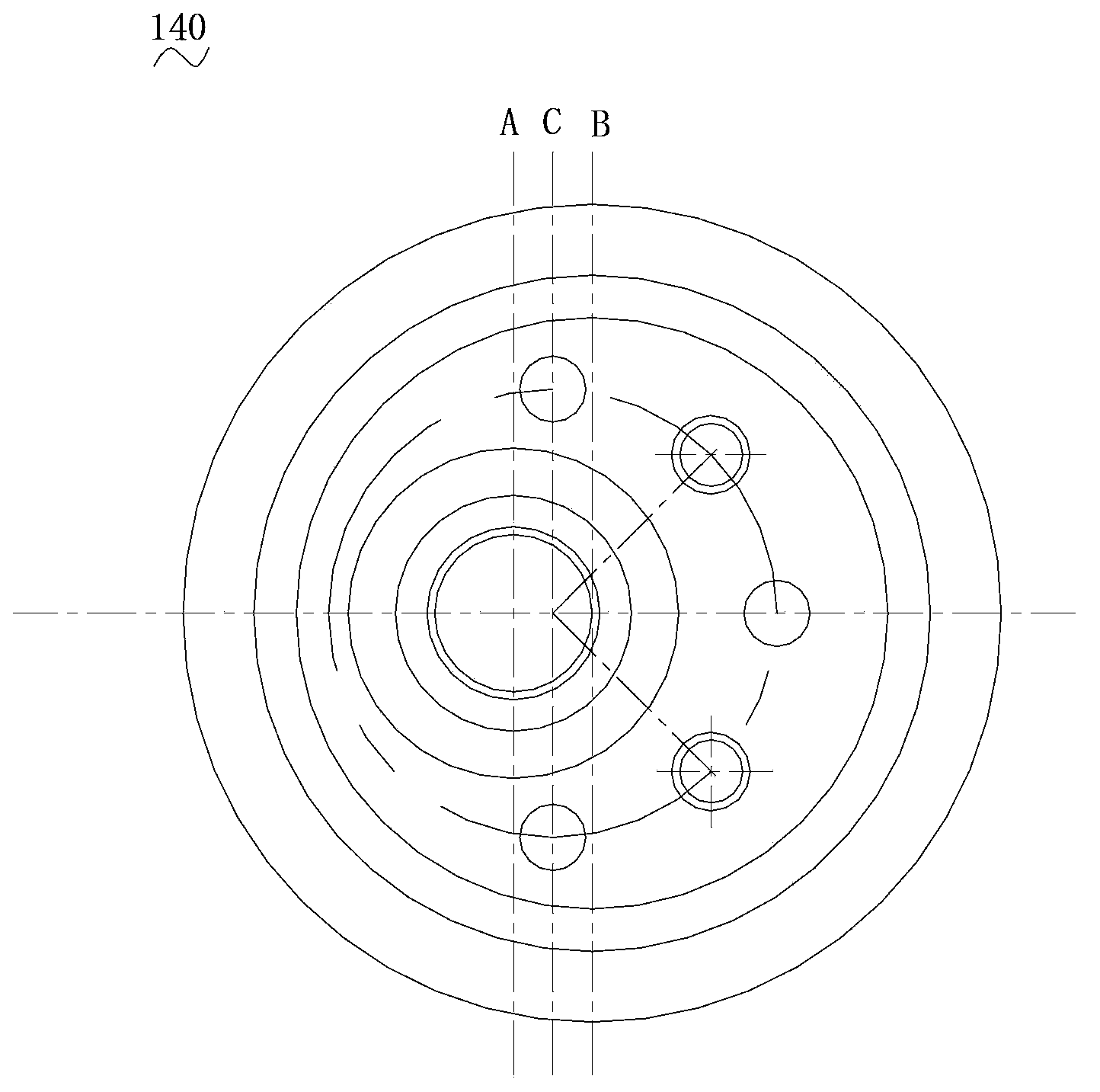

[0019] Please refer to figure 1 and figure 2 , the double-disk circular sand machine 100 of the present embodiment includes a casing 110, a rotating shaft 120 arranged inside the casing 110, a connecting piece 130 fixed on the rotating shaft 120, an integrated bearing 140 fixed on the connecting piece 130, and fixed respectively. The inner chassis 150 and the outer chassis 160 of the integrated bearing 140 , the intermediate shaft 170 , the bearing pressure plate 180 and the outer chassis bracket 190 . Rotary shaft 120 is typically a motor shaft. The bearing pressure plate 180 includes a bearing inner pressure plate 182 and a bearing outer pressure plate 184 .

[0020] Please refer to Figure 1 to Figure 3 , the integrated bearing 140 includes an inner ring 142 , a middle ring 144 and an outer ring 146 rotatably connected in the radial direction. The middle ring 144 of the integrated bearing 140 is fixed to the connector 130 by screws, wherein the middle ring 144 is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com