Honing rod welding device

A technology of welding device and honing stick, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of low welding processing efficiency, difficult clamping of honing stick bracket and honing stick, etc., and achieves simple structure and convenient use Reliable, easy-to-manufacture results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

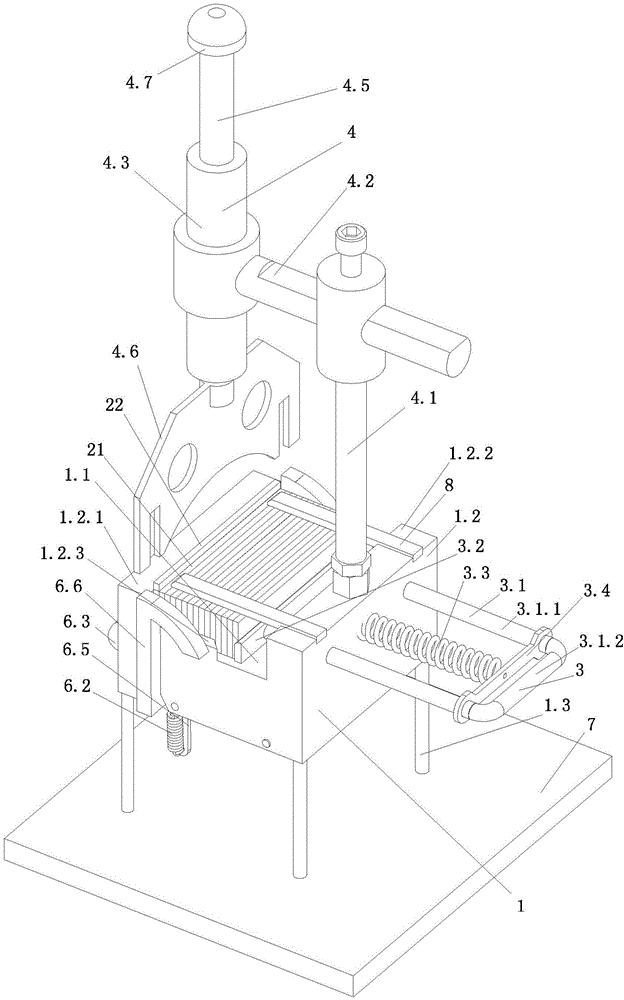

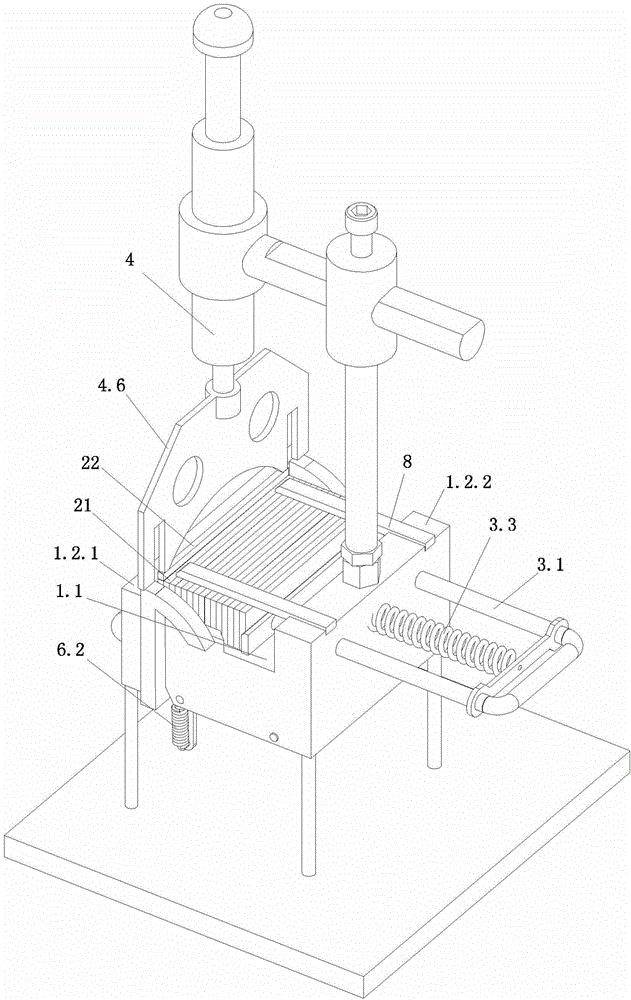

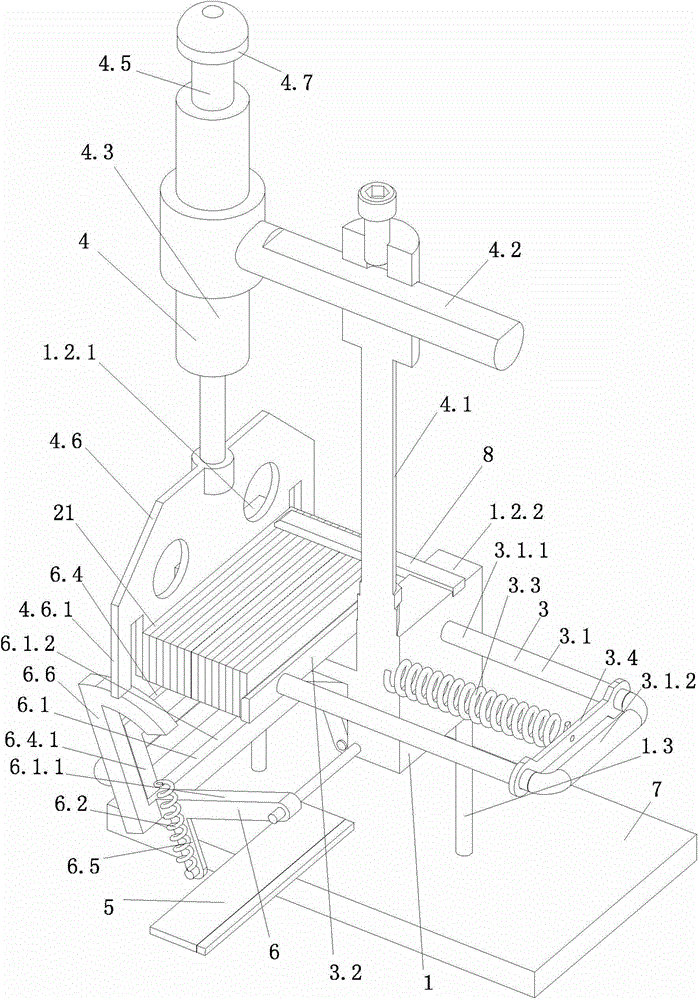

[0021] In the following, the technical solutions of the present invention will be further described in detail through embodiments and in conjunction with the drawings.

[0022] Such as figure 1 , figure 2 As shown, the present invention includes a frame 1. The frame 1 is provided with a frame mounting portion 1.1 that can store a plurality of honing rod supports 21, and the honing rod supports 21 sequentially placed on the frame mounting portion 1.1 are pushed and clamped in The bracket clamping mechanism 3 on the frame 1 presses the honing rod 22 on the upper end of the first honing rod support 21 to prepare for the welding operation and can weld the honing rod support that has been welded to the honing rod welding group 5 from the machine The honing rod pressing device 4 that is removed from the discharge hole opened on the frame 1, the supporting mechanism 6 that prevents the honing rod holder 21 from falling from the discharge hole during welding operation; the honing rod pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com