Full-automatic pipetting station and application thereof

A workstation and pipetting technology, which is applied to measuring tubes/pipettes, chemical instruments and methods, laboratory containers, etc., and can solve the problems of large wear and tear of pipetting mechanisms and large operating noise of assembly and debugging mechanisms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0082] In order to better understand and illustrate the present invention, the present invention will be further described in detail below with reference to the accompanying drawings.

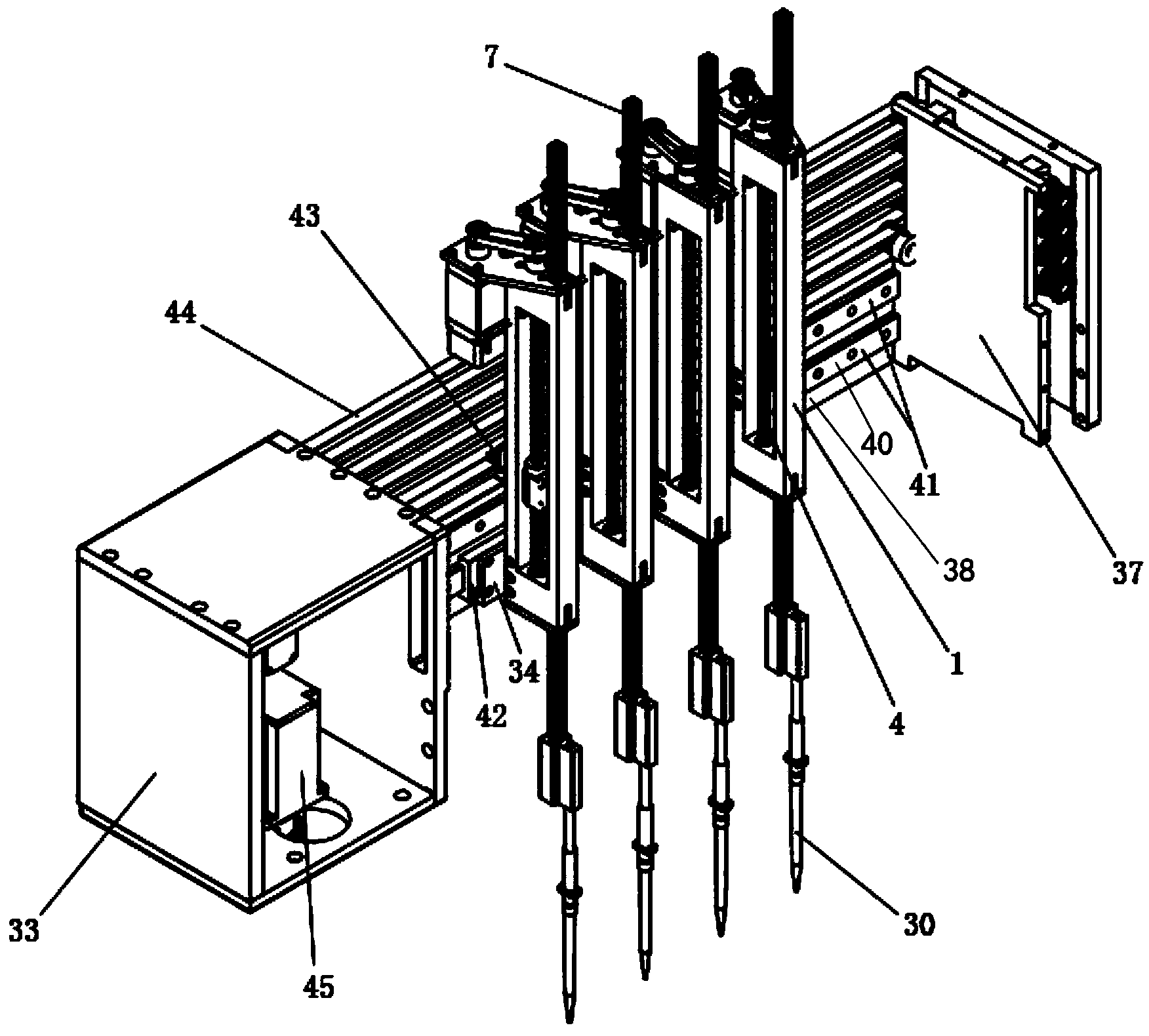

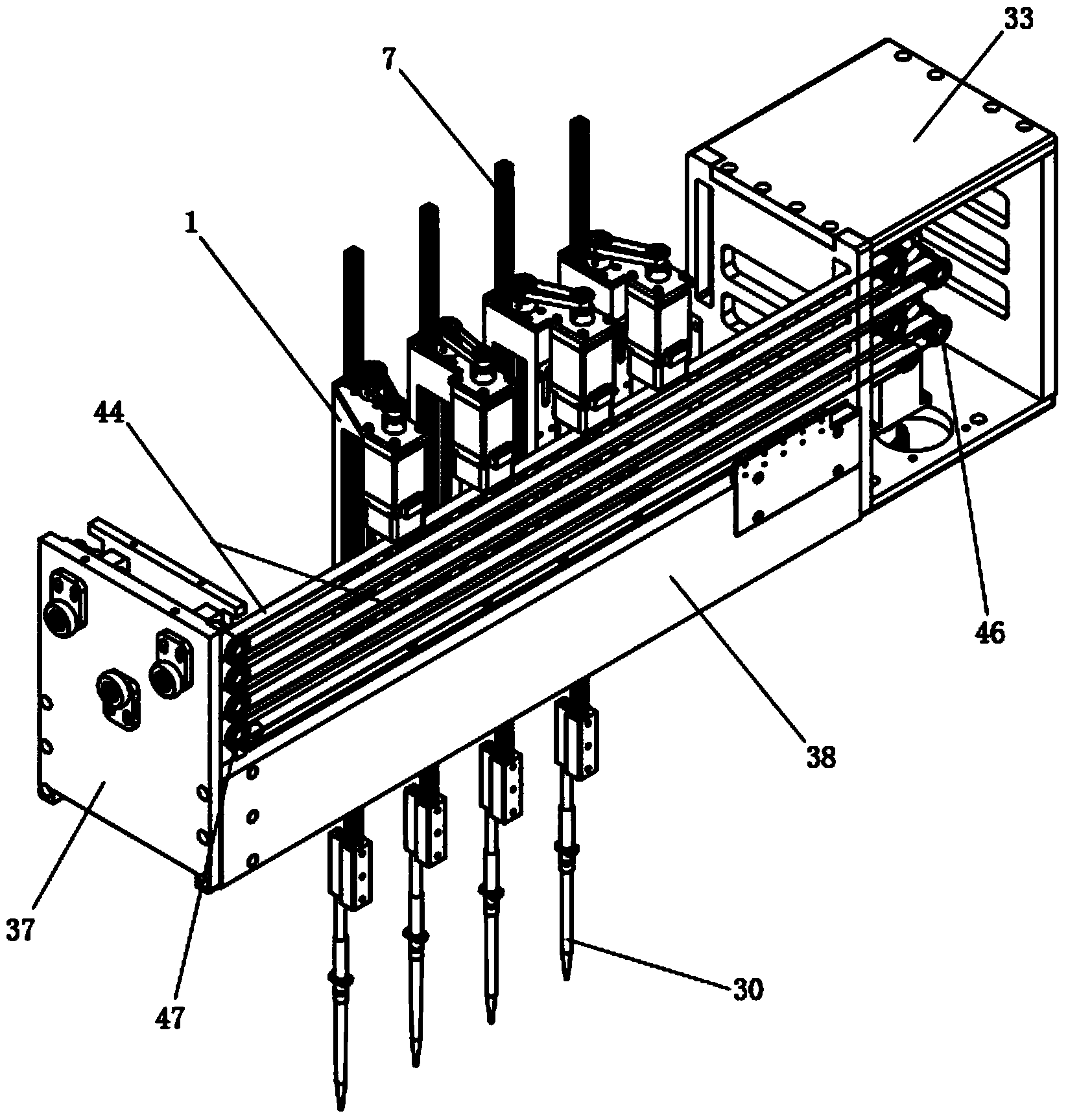

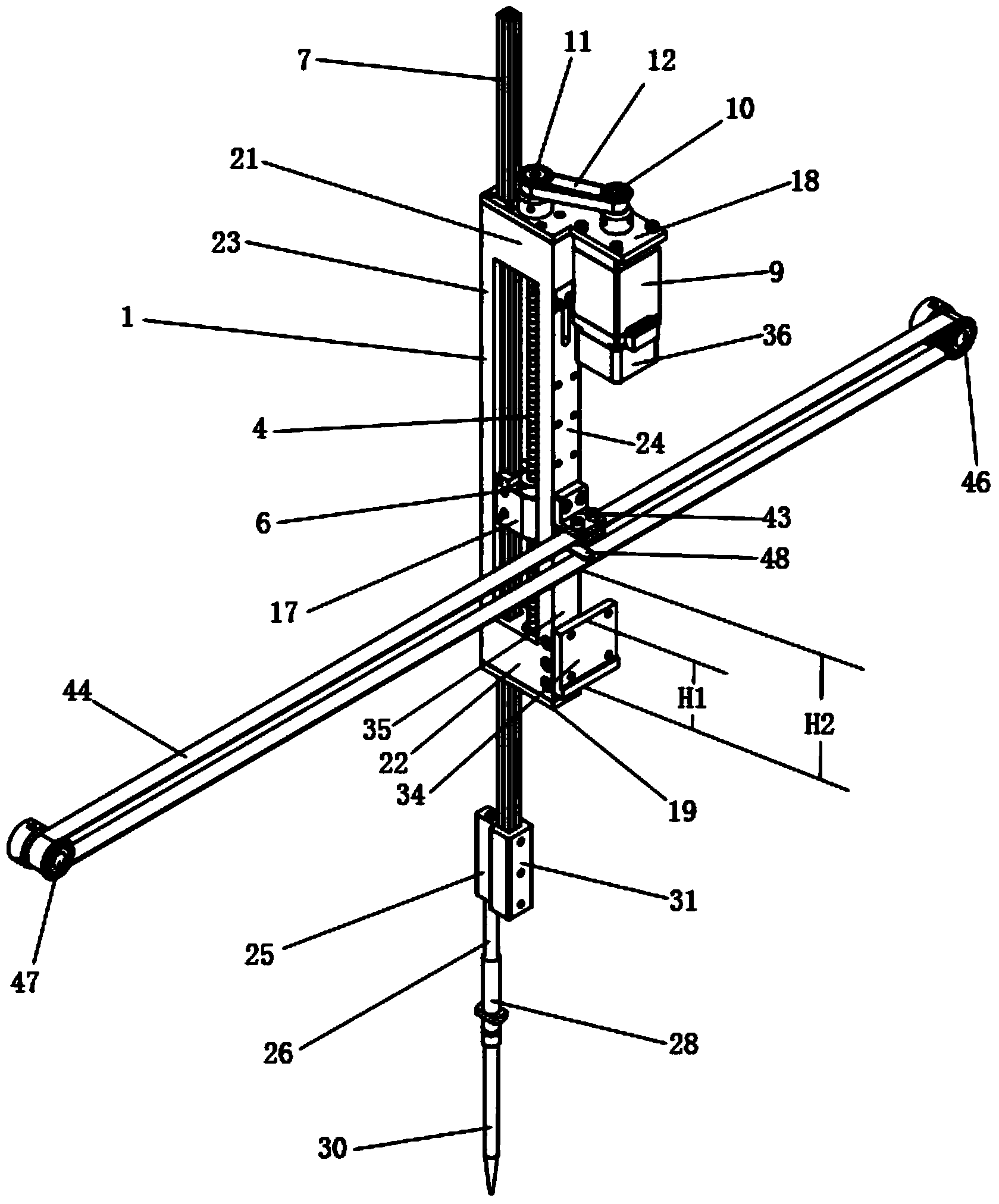

[0083] figure 1 It is a first-direction schematic diagram of partial internal devices of a pipetting workstation according to a preferred embodiment of the present invention. figure 2 It is a schematic view in the second direction of the partial internal device of the pipetting workstation according to a preferred embodiment of the present invention.

[0084] The liquid pipetting workstation of the present invention generally has eight liquid pipetting mechanisms 38 for implementing liquid sample addition and liquid transfer. The eight pipetting mechanisms are divided into two groups arranged in parallel, and four pipetting mechanisms in each group are assembled side by side. figure 1 It shows a schematic diagram of the internal parts of the liquid pipetting workstation of the present invent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com