Method for logically controlling combined chopped waves of power switch devices of switched reluctance motor

A technology of power switching devices and switched reluctance, which is applied in the direction of electronically commutated motor control, control systems, electrical components, etc., can solve the problems of uneven heating of power switching devices and reduce power switching devices, so as to prolong life and reduce switching costs. Stress, the effect of solving uneven heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

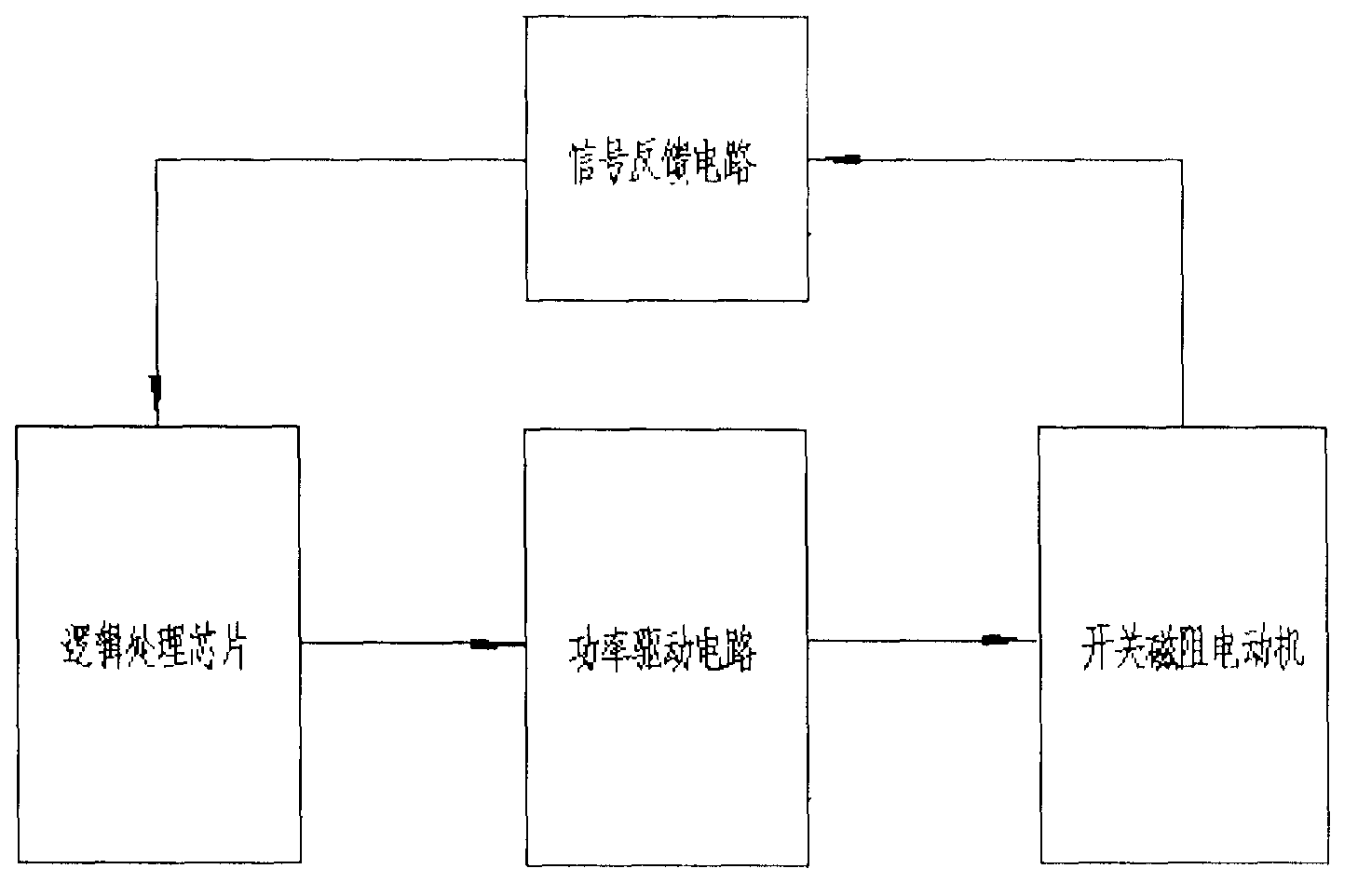

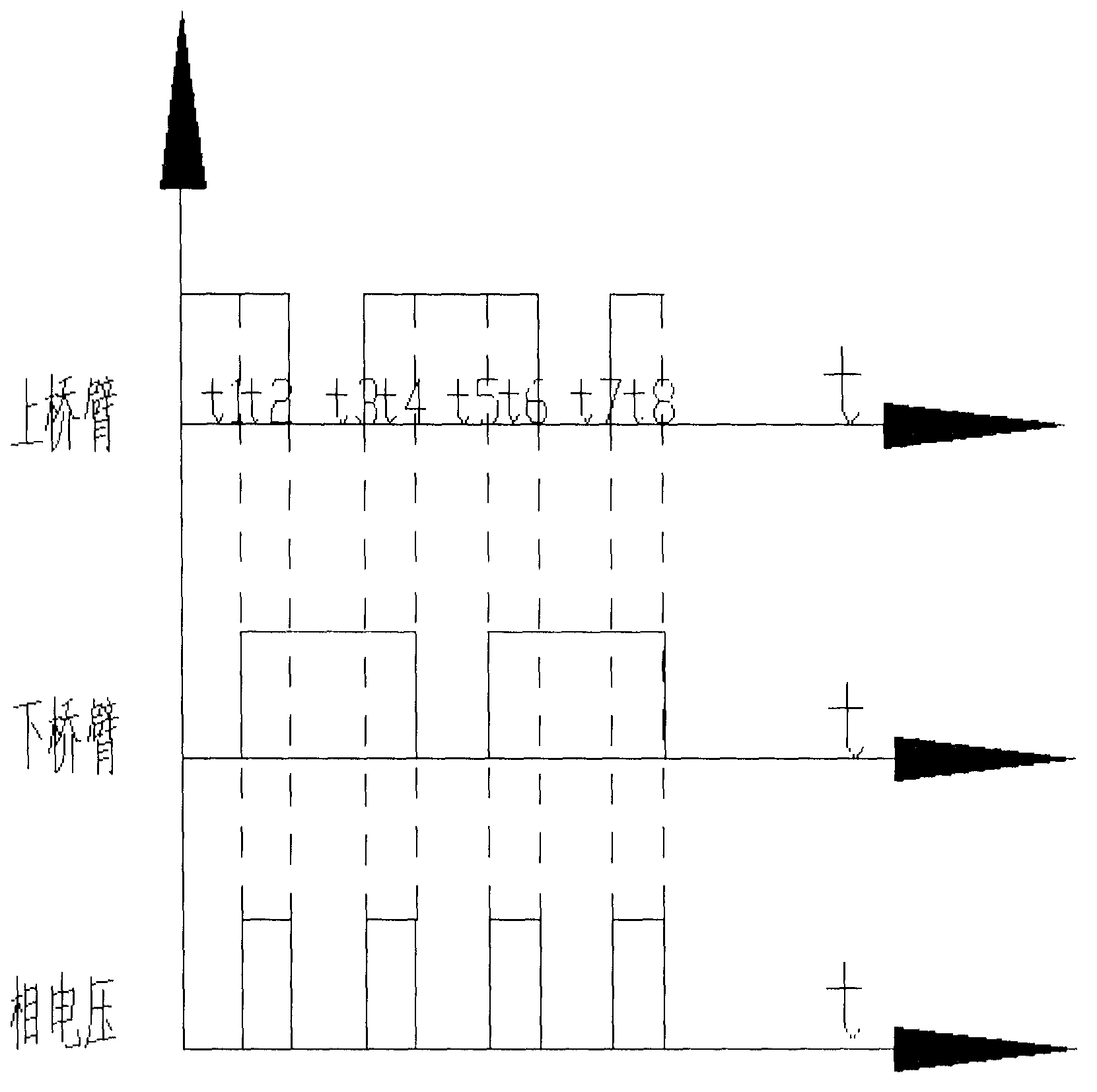

[0015] In the switching reluctance motor power switching device combined chopping logic control method of the present invention, at first a combined chopping logic control circuit is designed, such as figure 1 As shown, the combined chopping logic control circuit includes a signal bow 'feedback circuit connected with the switched reluctance motor, and the said double bow 'feedback circuit is connected with a logic processing chip and a power drive circuit in turn; as figure 2 As shown, in the power drive circuit, the three-phase power supply input is provided to the power switch tube after bridge rectification and filter capacitor C, and the power switch tube forms an asymmetric bridge topology circuit structure, and each phase is composed of two power switch tubes 1. Two diodes and motor windings are connected in series to form upper and 'two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com