Gravity type steel wire conveying belt horizontal passing-through demagnetization frame device

A conveyor belt, gravity type technology, applied in the field of wire conveyor belt degaussing devices, can solve the problems of conveyor belt tearing, demagnetizer damage and other problems, and achieve the effect of ensuring safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

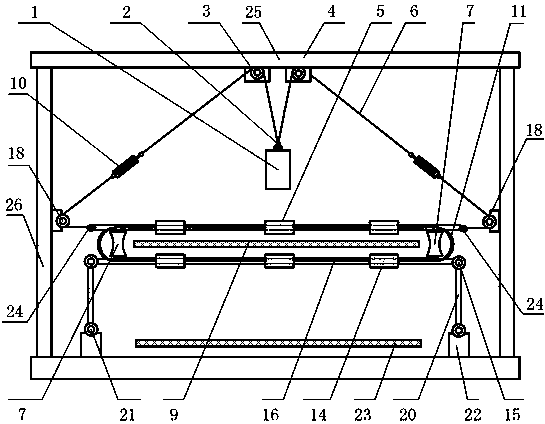

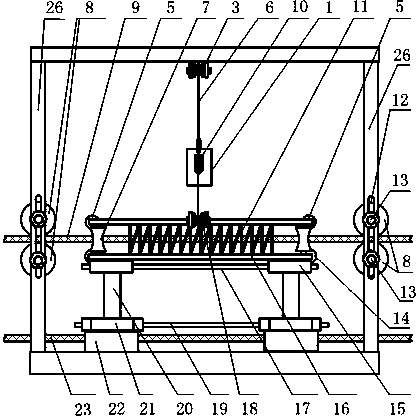

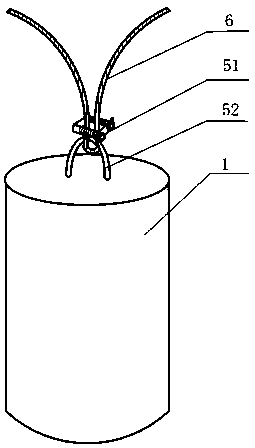

[0020] see figure 1 and figure 2 , a gravity-type steel wire conveyor belt horizontally traverses a degaussing frame device, comprising a degaussing frame frame 25, a steel wire rope 6, a weight 1, a diverting pulley 18, a degaussing coil frame 16, and a rocker mechanism;

[0021] Two upper pulleys 3 are installed side by side on the upper beam 4 of the degaussing frame frame 25, and a diverting pulley 18 is installed on the side beams on both sides of the degaussing frame frame frame 25. One end of the wire rope 6 is connected to the left side of the degaussing coil frame 16 in the degaussing frame frame frame 25. Side connection, that is, degaussing coil frame and wire rope left side connection point 24, the other end passes through diverting pulley 18, upper pulley 3, heavy bell 1, upper pulley 3, diverting pulley 18 and is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com