Heat transfer type server chassis

A server and chassis technology, applied in the direction of instruments, electrical digital data processing, digital data processing components, etc., can solve server heat dissipation and other problems, achieve the effects of small size, save space in the chassis, and increase service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Specific embodiments of the present invention are described with reference to the above drawings.

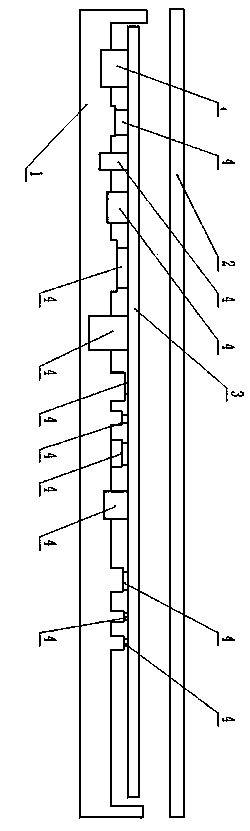

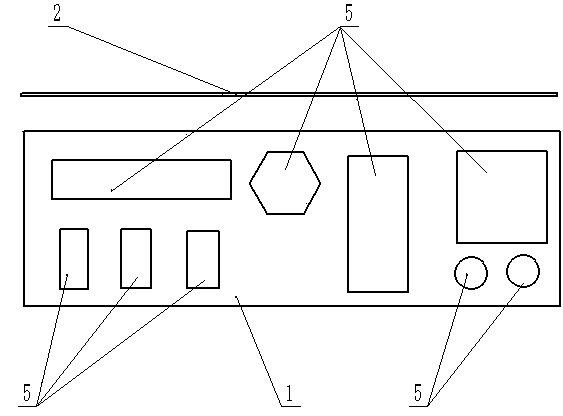

[0017] Such as figure 1 The sectional view of the server case of the present invention includes a case base (1), a case upper cover (2) and a server (3); the bottom plate of the case base (1) and the four side plates of the bottom plate are Cast one-piece structure; the casing base (1) is a metal shell with good thermal conductivity, and the inside of the bottom plate of the casing base (1) is based on the electronic components ( 4) The structural shape is cast with a groove type or a convex structure, so that the bottom plate of the chassis base (1) can be in close contact with the electronic components (4) that generate a large amount of heat on the server (3); There is a space between the bottom plate of the casing base (1) and the electronic components with low heat generation on the server (3), and they are not in contact; the outer surface of the bottom plate of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com