Method for reinforcing old concrete gravity dam with cracks through FRP sheets

A technology of FRP sheets and concrete, which is applied in the direction of gravity dams, dams, water conservancy projects, etc., and can solve the problems of rare large-volume concrete structures reinforced by FRP sheets

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

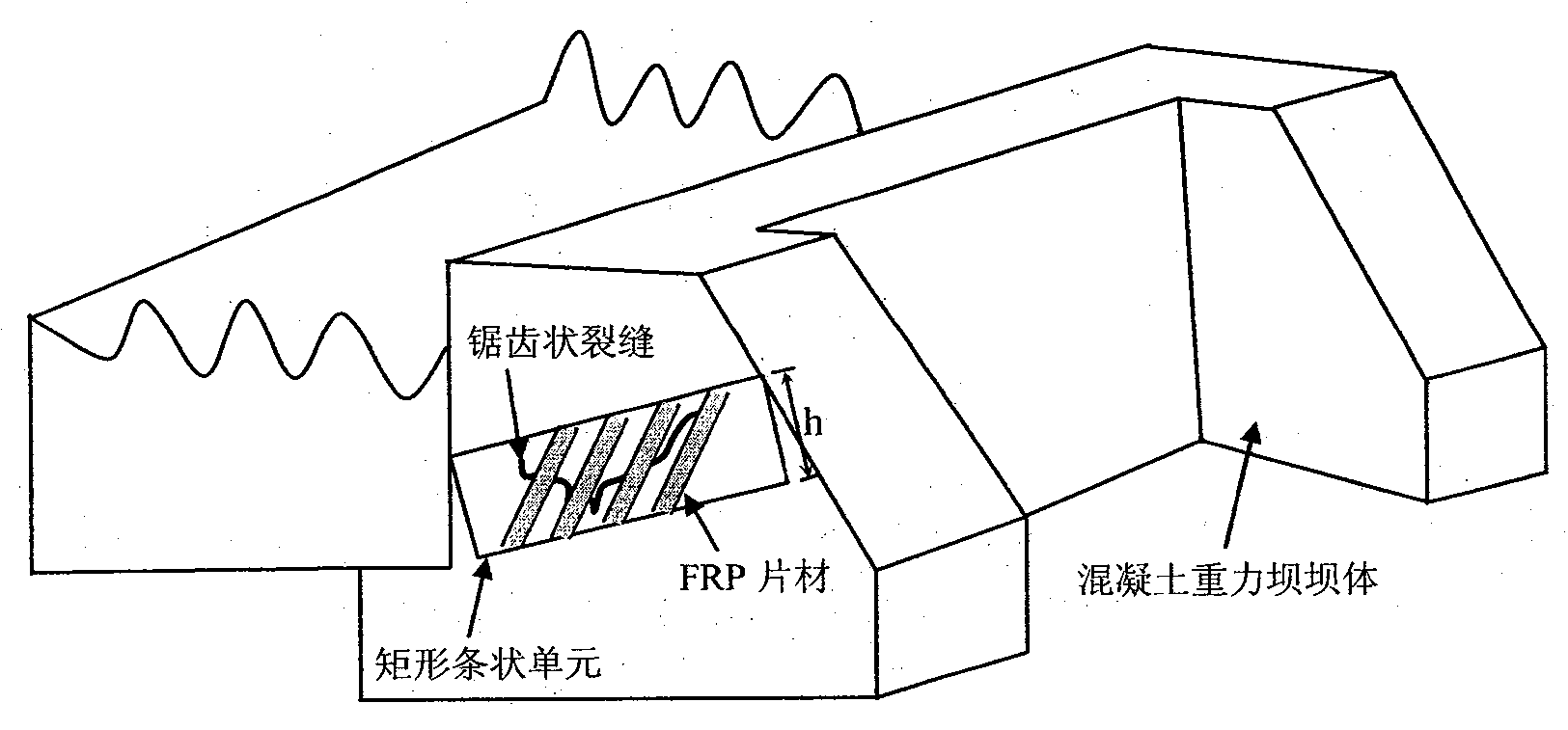

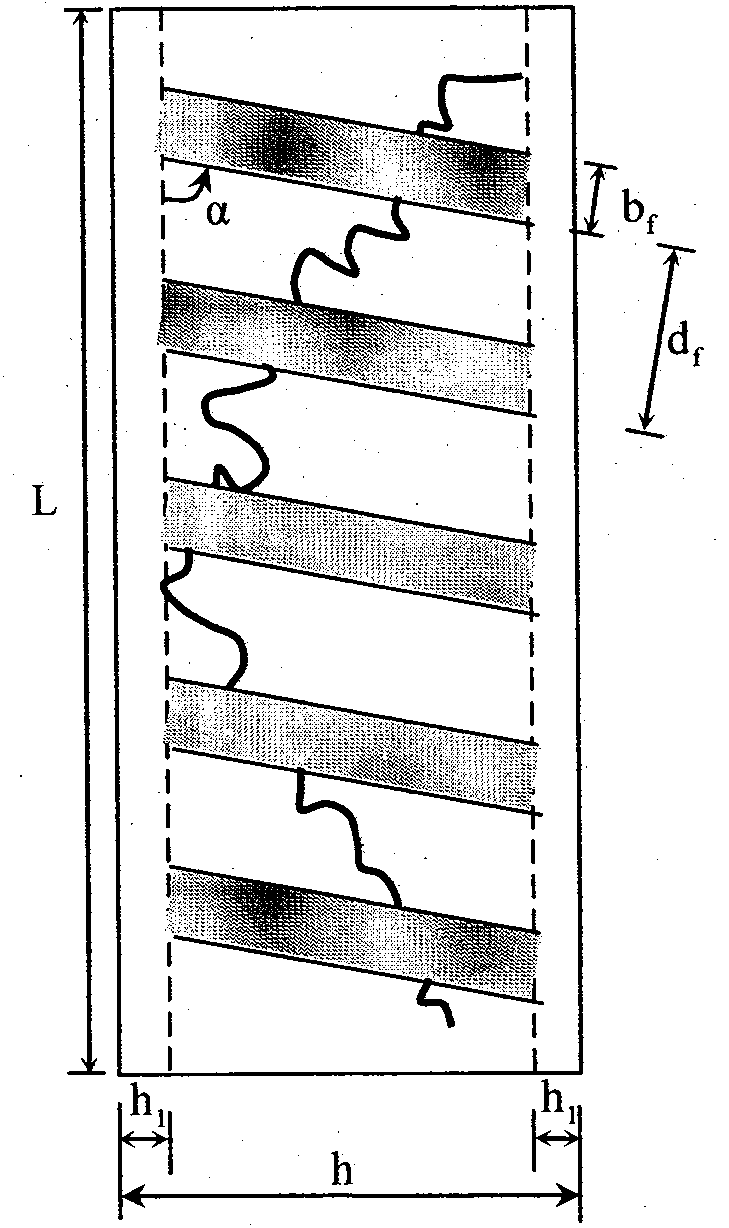

[0035] The present invention also provides the implementation steps of the old concrete gravity dam body with cracks in the FRP sheet reinforcement, as follows.

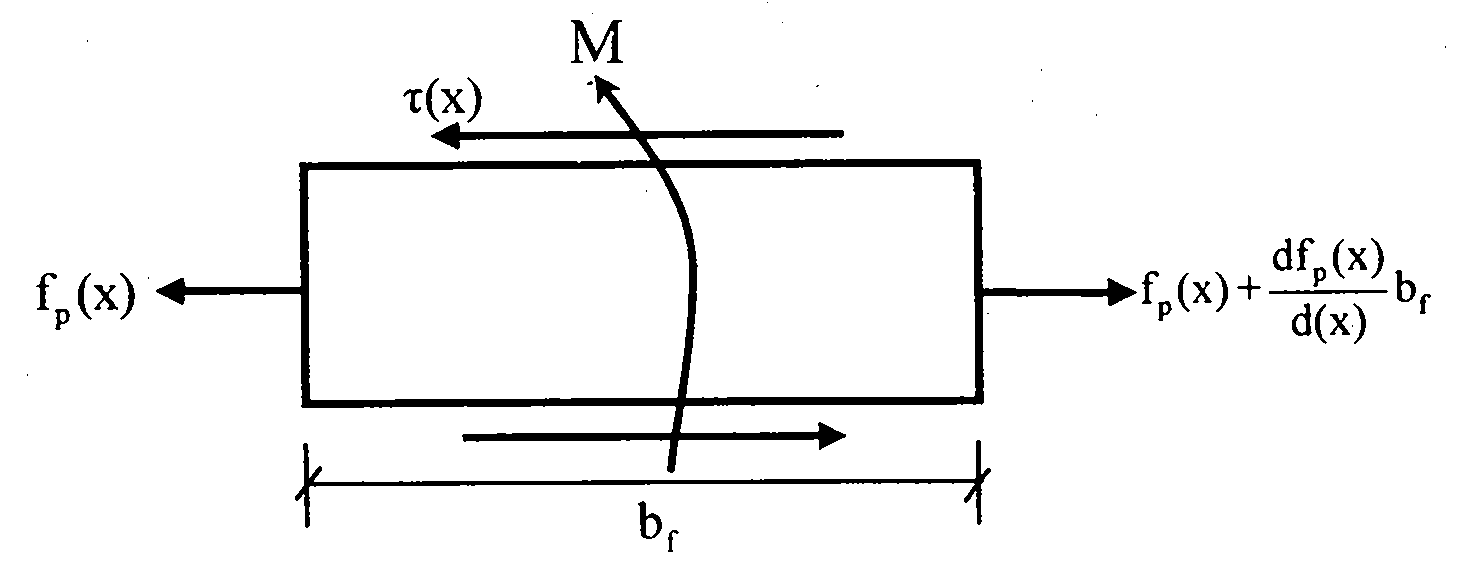

[0036] (1) Regardless of the slip effect between the FRP sheet and the concrete of the dam body, the maximum shear stress when cracks occur in the old concrete gravity dam working with cracks is obtained through the corresponding method established.

[0037] (2) With the help of the bond-slip (δ-τ) constitutive relationship between the FRP sheet and the concrete interface of the dam body, the bond-slip model is used to obtain the old concrete with cracks when considering the bond-slip deformation of the interface For the maximum shear stress when cracks occur in the gravity dam body, the larger value of the maximum shear stress calculated by the above two methods is taken as the basis for the design and construction of FRP sheets.

[0038](3) Select the typical rectangle of the main cracks on the surface of the old c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com