Industrial airtight container and connection method thereof

A technology of sealed containers and connection methods, which is applied in the field of industrial sealed containers and their connections, and can solve the problems of high processing environment requirements, long construction period, and welding quality depending on workers' operation level and proficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the technical solution of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

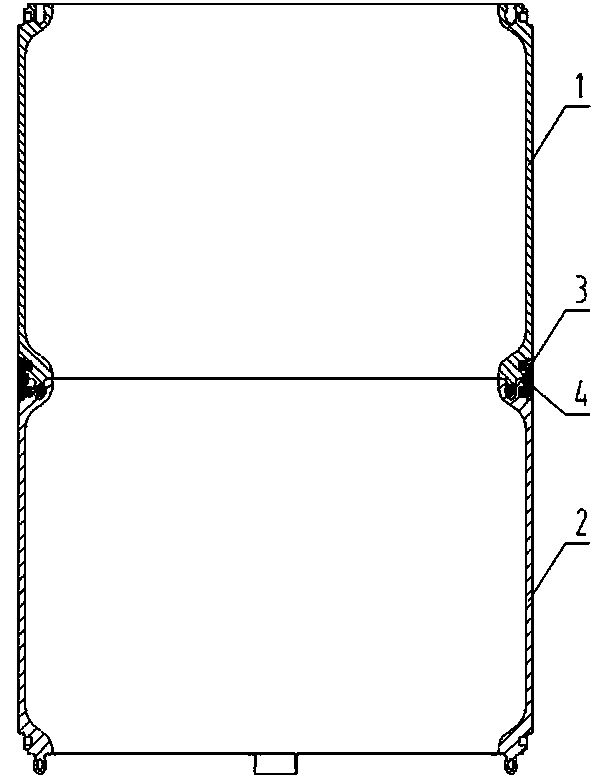

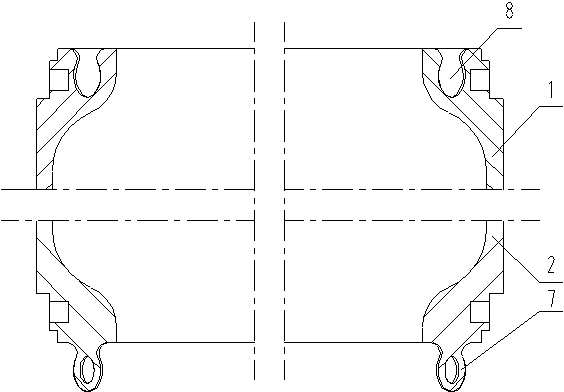

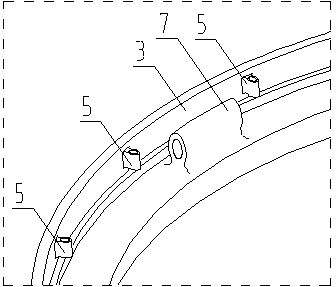

[0040] Please refer to Fig. 1 and Fig. 2, Fig. 1 is a schematic diagram of partial connection of a specific embodiment of the industrial sealed container provided by the present invention; Fig. 2 is a partial cross-sectional view of the industrial sealed container shown in Fig. 1 .

[0041]It should be noted that the industrial airtight container mentioned in this article refers to a metal or non-metal container with relatively high hardness and a large extension size. It is necessary to ensure both the connection strength and the tightness at the same time to meet the needs of industrial use. Obviously, this method can also be used for daily necessities. At the same time, the first sealed chamber 1 and the second sealed chamber 2 are only the definitions of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com