Push rod type automobile suspension system

A suspension system and automobile technology, which is applied to the suspension, vehicle parts, cantilever mounted on the pivot, etc., can solve the problems that cannot meet the comfort and operation accuracy at the same time, and achieve the reduction of requirements, guarantee of accuracy, and elimination of The effect of longitudinal force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

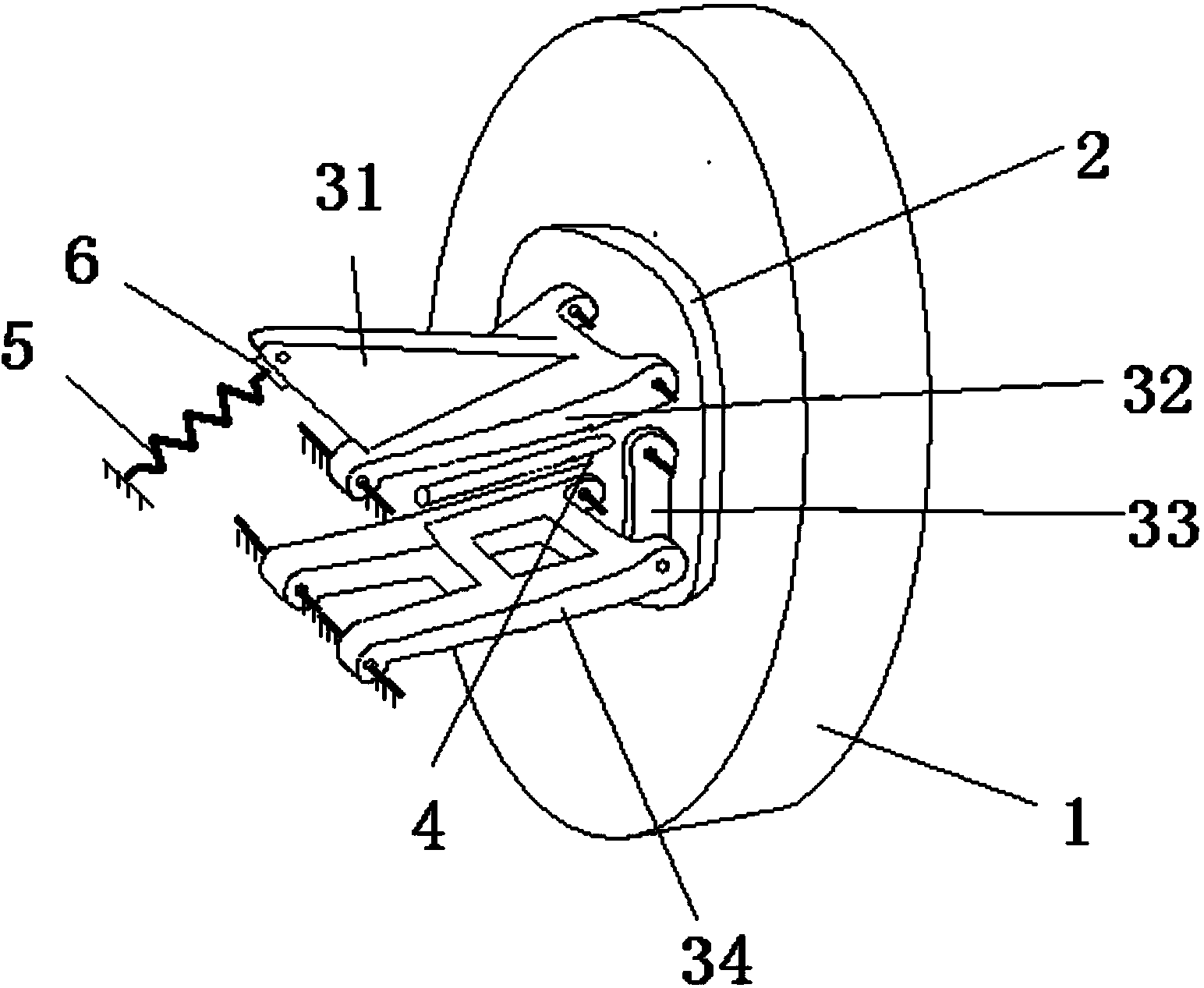

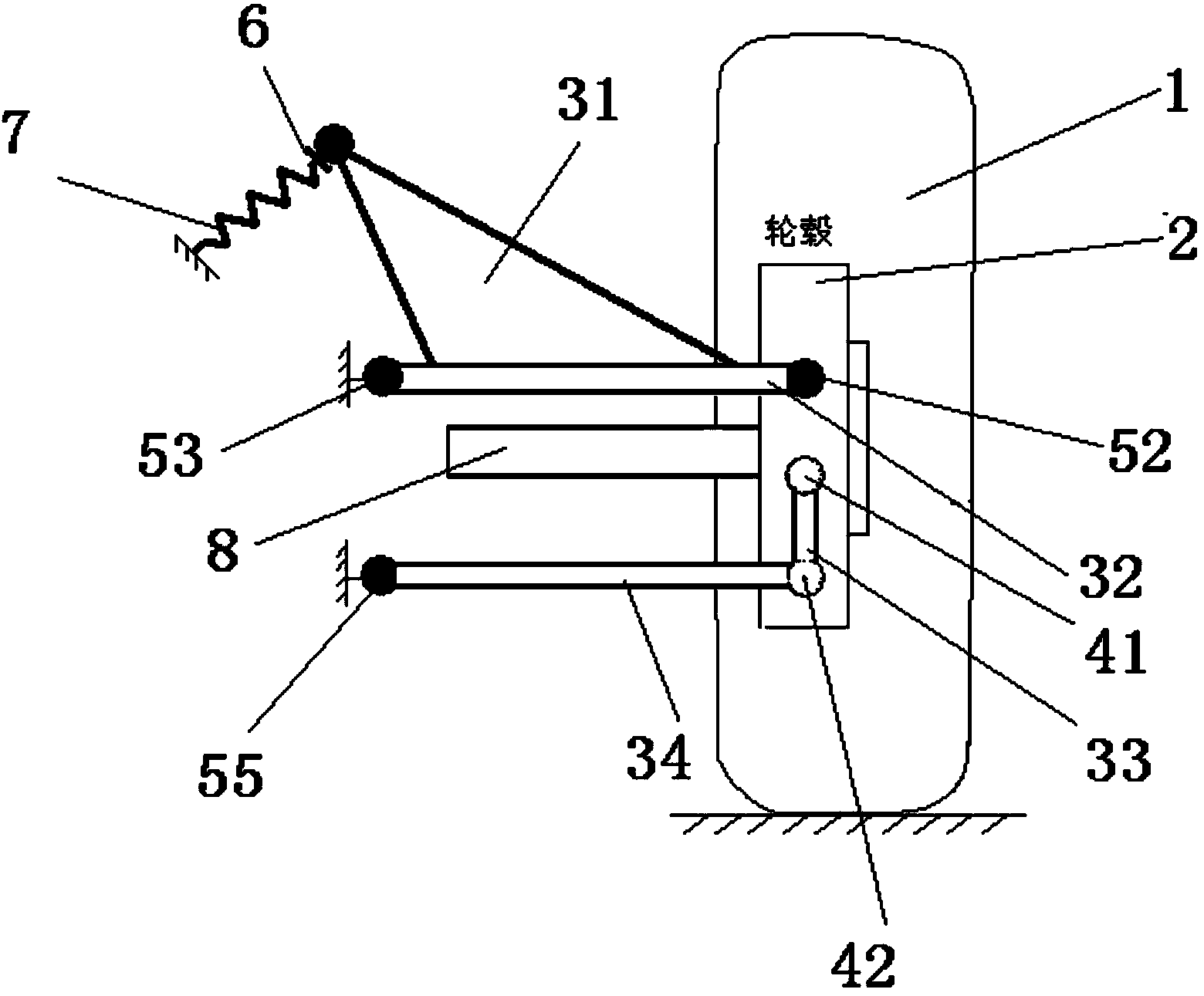

[0023] Such as figure 1 As shown, a kind of automobile suspension system comprises wheel hub 2, suspension control arm, transmission shaft 8 positioned at the center of wheel hub, spring 7 and shock absorber 6. The suspension control arm includes a push arm 31 , an upper arm 32 , a short arm 33 and a lower arm 34 .

[0024] Such as figure 2 , 3 , 4, the push arm 31 is vertically fixed on the upper arm 32, its top end is fixed with a shock absorber 6, and is connected with the vehicle frame through a spring 7 to jointly support the weight of the vehicle body. The upper arm 31 is A-shaped, its first end point 53 is fixed on the vehicle frame through a hard bushing, and the second end point 51 and the third end point 52 are fixed on the wheel hub through a hard bushing, and about the drive shaft 8 The vertical line of symmetry.

[0025] Due to the A-shaped structure of the upper arm 32, the upper arm and the vehicle body have only one connection point, so the second end poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com