Ticket production device and ticket production method

A single-ticket, cut-off unit technology, applied to printing devices, temperature recording methods, printing, etc., can solve problems such as defective, lost, and interference cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

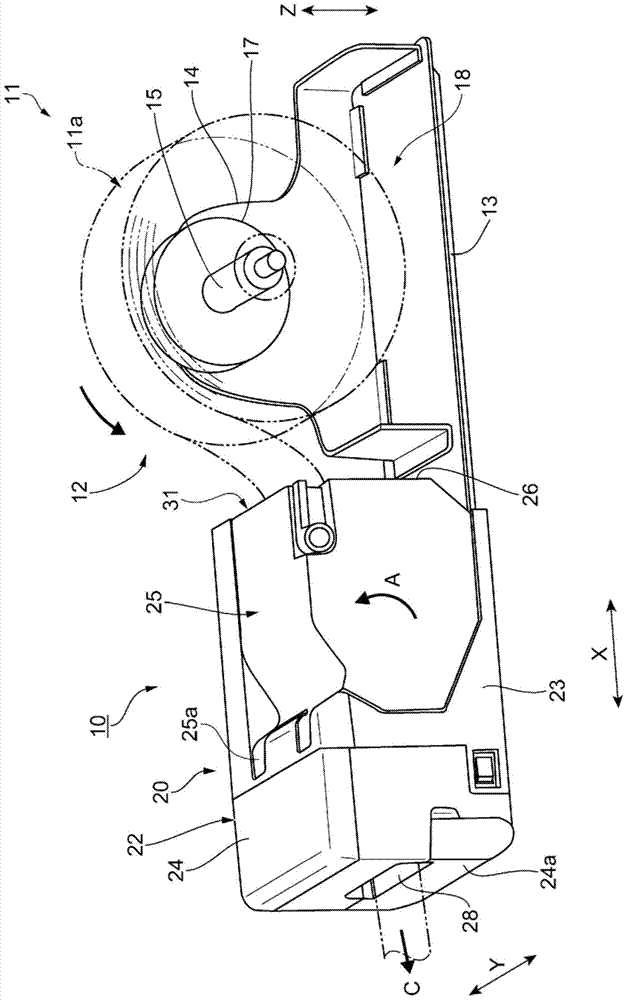

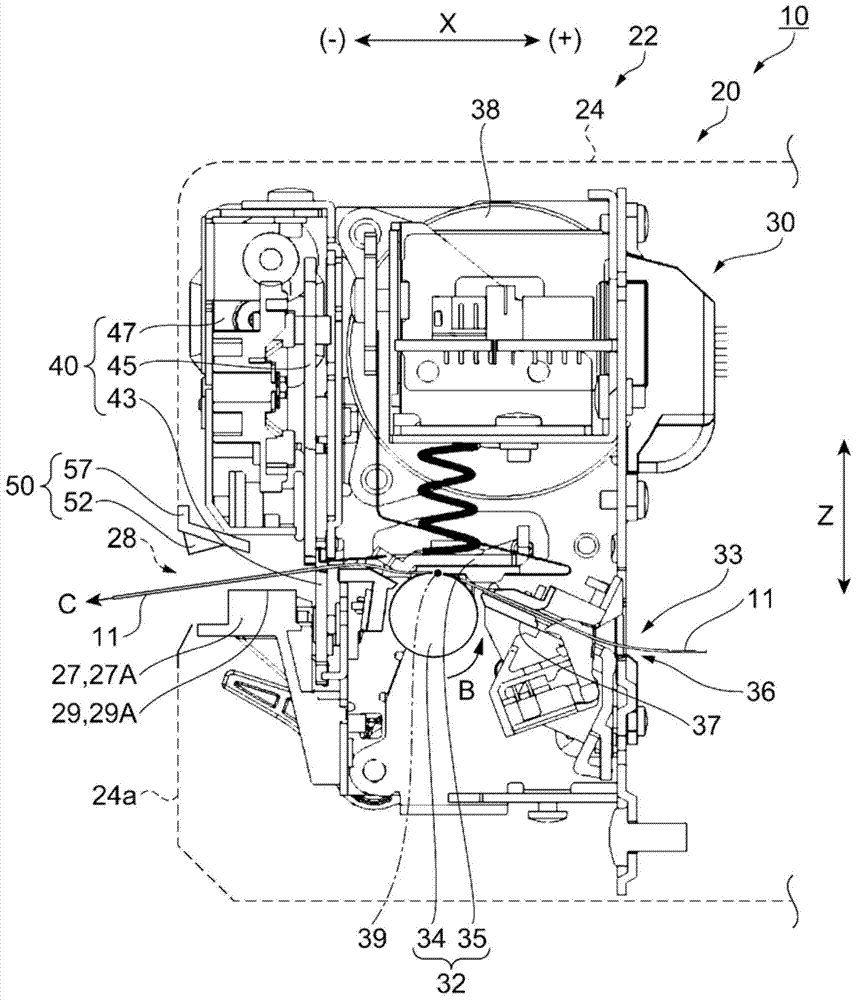

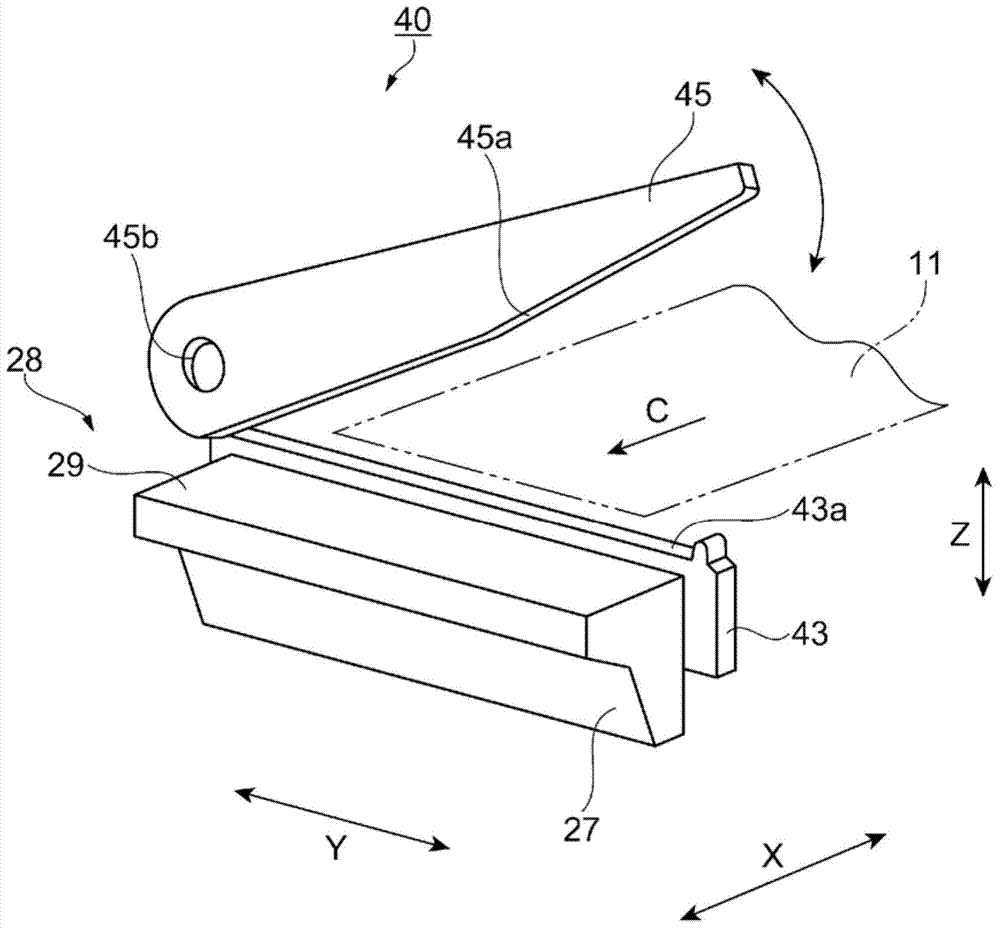

[0066] Here, refer to figure 2 as well as Figure 4 The recording paper posture detection unit according to the first embodiment will be described. Figure 4 It is a figure explaining the recording paper posture detection unit which concerns on 1st Embodiment, (a) is a perspective view seen from the recording paper discharge direction, (b) is a schematic view seen from S direction in figure (a) , (c) is a schematic view observed from the T direction in Figure (a). Figure 4 The shown X direction, Y direction and Z direction represent the same figure 1 The indicated X direction, Y direction, and Z direction are the same directions.

[0067] Such as figure 2 As shown, the recording paper posture detection unit 50 is disposed at a position facing the paper guide surface 29 of the above-mentioned paper table 27 at the paper outlet 28 portion of the exterior case 22, that is, at a position opposite to the completed printing remaining on the paper guide surface 29. The positi...

no. 2 approach

[0093] Here, refer to Figure 6 A recording paper posture detection unit according to a second embodiment will be described. Figure 6 It is a figure explaining the recording paper attitude|position detection means in 2nd Embodiment. Figure 6 The shown X direction, Y direction and Z direction represent the same figure 1 The indicated X direction, Y direction, and Z direction are the same directions. In addition, the same code|symbol is attached|subjected to the same structure and content as 1st Embodiment, and description is abbreviate|omitted.

[0094] Such as Figure 6 As shown, the recording paper posture detection unit 50A of the second embodiment includes a plurality of detectors 60A arranged in a row over the entire paper width along the paper width direction of the recording paper 11 on the paper guide surface 29A of the paper table 27A. Therefore, the plurality of detectors 60A face the back surface of the printed recording paper 11 remaining on the paper table 27...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com