Fixture for machining holes in large and small ends of automotive engine connecting rod

A technology for automobile engines and large and small heads, which is used in metal processing machinery parts, manufacturing tools, metal processing equipment, etc., can solve the problems of wasting processing time, reducing work efficiency, increasing processing costs, etc., to ensure accuracy and quality, and improve work. Efficiency and saving installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

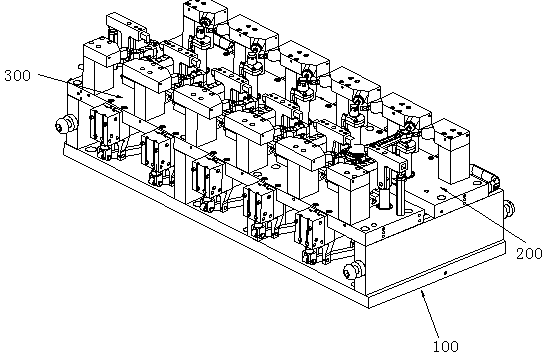

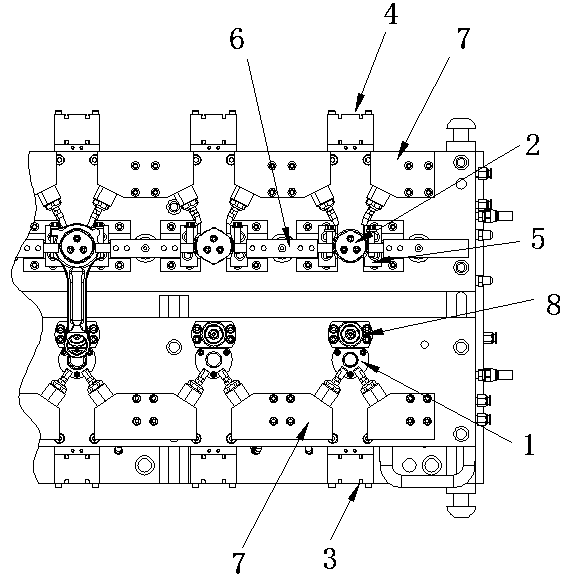

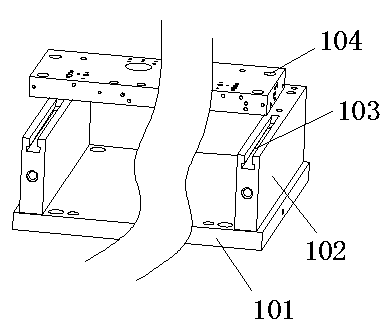

[0036] Such as Figure 1-2 As shown, a fixture for processing the large and small head holes of automobile engine connecting rods includes a small end fixture body 200, a large end fixture body 300, a support seat 100 and a plurality of clamping and positioning units, the small end fixture body 200 and the large end fixture body 200 One of the relative support seats 100 of the clamp body 300 is movable; each clamping positioning unit includes a small-end positioning pin 1 arranged on the small-end clamp body 200 and a large-end positioning pin 2 arranged on the large-end clamp body 300 , driving the small head positioning pin 1 to pump the small head positioning pumping device 3, driving the big head positioning pin 2 to pump the big head positioning pumping device 4, the positioning device 5 for positioning the workpiece and the clamping device 6 for clamping the workpiece, the positioning The device 5 and the clamping device 6 are correspondingly arranged on the big head fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com