Dry desulfurization spray nozzle

A dry desulfurization and nozzle technology, applied in separation methods, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of poor desulfurization efficiency, increased equipment energy consumption, inappropriate selection of dry desulfurization nozzle materials, etc. Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

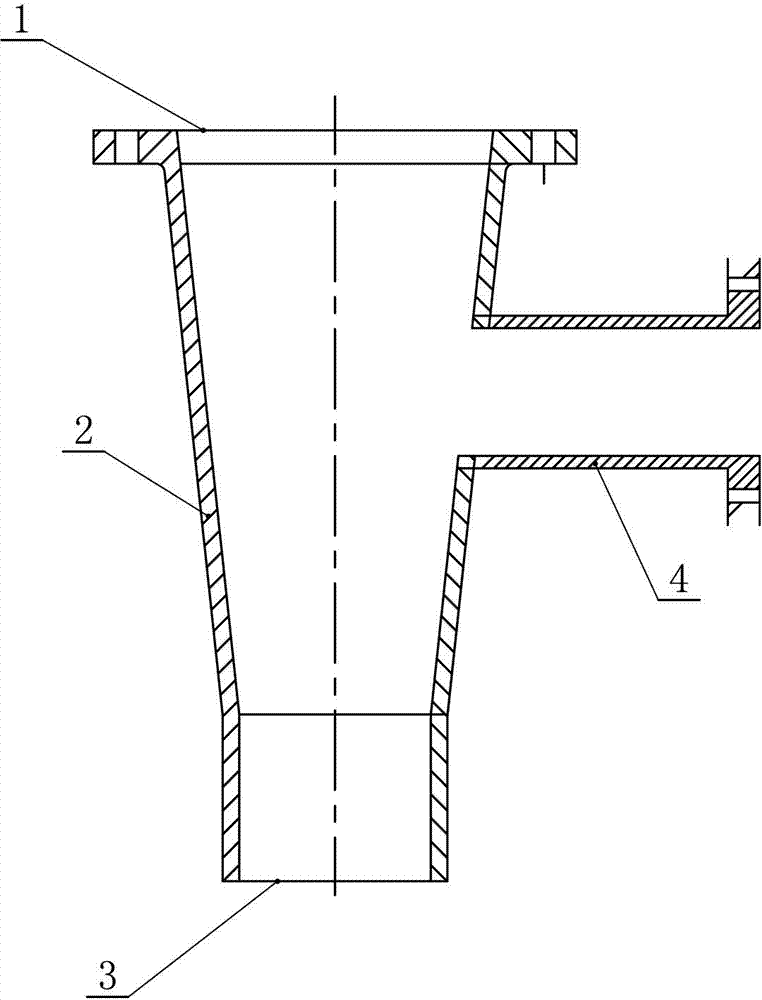

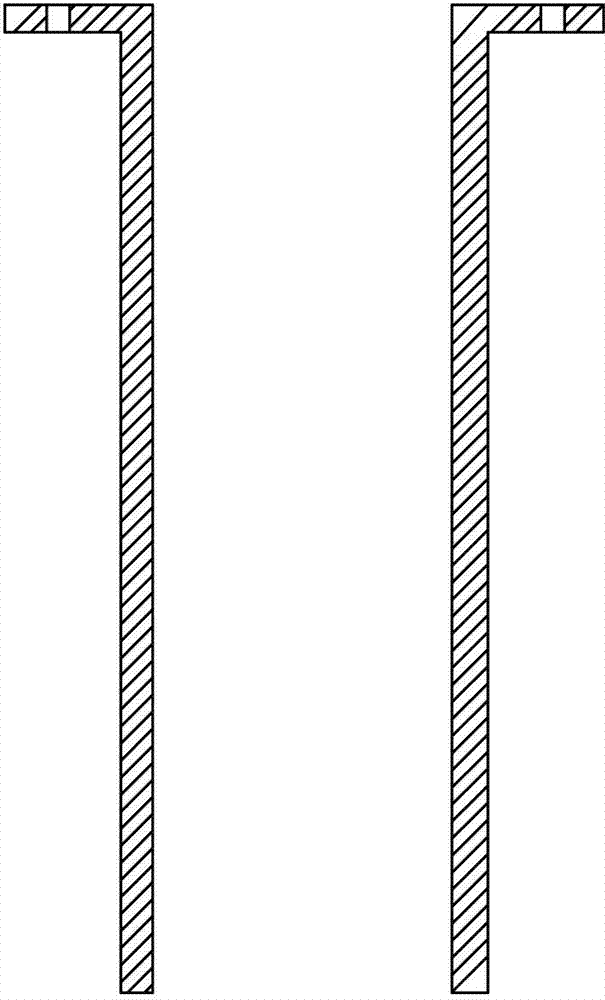

[0014] The present invention as figure 1 As shown, a dry desulfurization nozzle includes a blast pipe 2, which is characterized in that: the rear end of the blast pipe 2 is connected to the air outlet 1, and the outlet 1 is connected to the air source, and the diameter of the rear end of the blast pipe 2 is greater than that of the front end. The tapered pipe, the front end of the blast pipe 2 is the blast outlet 3. According to the dry desulfurization nozzle, it is characterized in that: the side of the tapered pipe in the middle of the air spray pipe 2 is provided with a desulfurization agent nozzle 4 . According to the dry desulfurization nozzle, it is characterized in that: the rear end of the blast pipe 2 is provided with a flange. According to the dry desulfurization nozzle, it is characterized in that: the rear end of the desulfurizer nozzle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com