A method for improving the quality of tobacco stems used in shredded tobacco

A tobacco stem and quality-enhancing technology, which is applied in the fields of tobacco, application, and tobacco treatment, can solve the problems of low utilization rate of raw materials, adverse effects on the overall quality of cigarettes, and low use value, and achieve improvement of physical and chemical indicators, good application effect, sensory The effect of internal quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

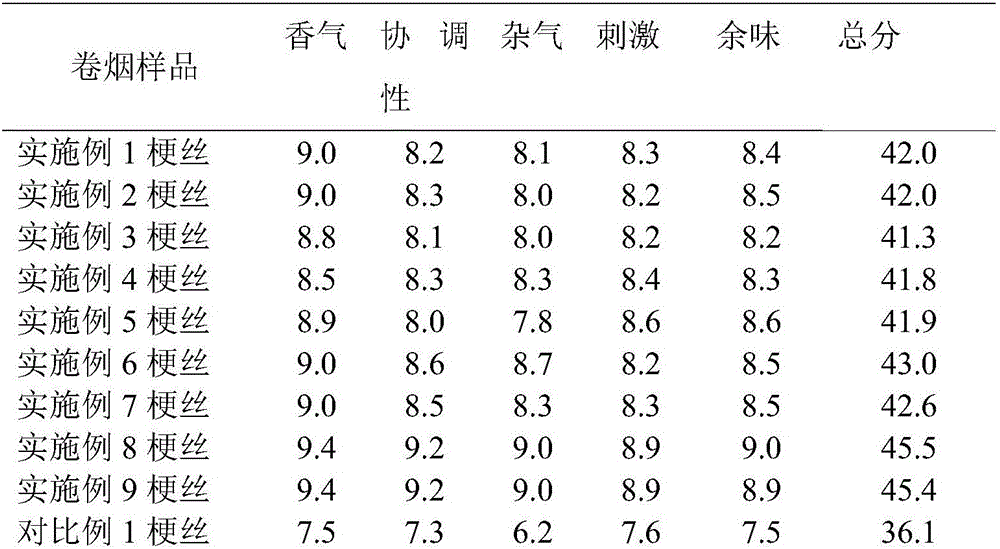

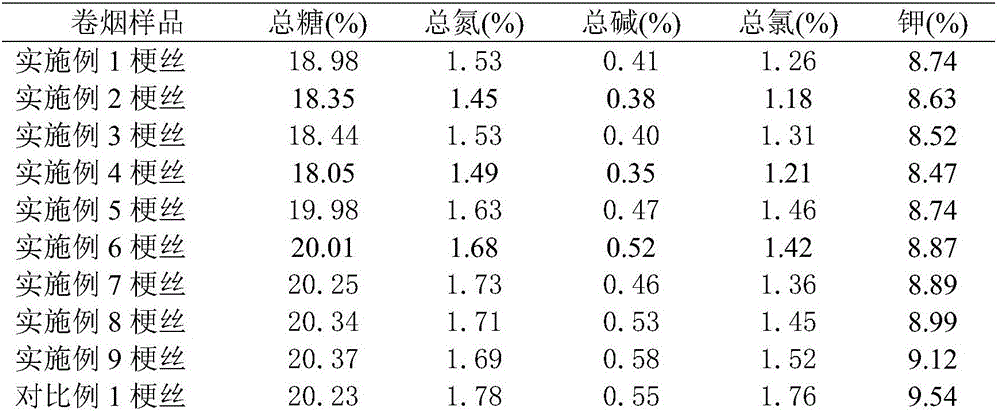

Examples

Embodiment 1

[0027] S1. Cleaning the tobacco stems (sourced from Guangdong China Tobacco Raw Materials Bank, which does not limit the present invention, those skilled in the art can use tobacco stems from other sources);

[0028] S2. Using 5 mL of hot water at 60°C to extract 1 g of tobacco stems for 50 min;

[0029] S3. After leaching the tobacco stems, filter to collect the extraction liquid and the extracted tobacco stems respectively; dispose of the extraction liquid separately, squeeze the tobacco stems dry, cut into shreds to obtain cut stems, and dry the cut stems to be evaluated.

[0030] The processes such as pressing stems, squeezing, and drying refer to existing conventional technologies.

[0031] The gap between the rolls of the stalk is set at 0.7-1.0mm, HDT expansion technology is adopted, and the temperature is set at 200°C-220°C.

Embodiment 2

[0033] S1. Clean the tobacco stems;

[0034] S2. Using 20 mL of hot water at 60°C to extract 1 g of tobacco stems for 30 min;

[0035] S3. After leaching, filter to collect the extraction solution and the extracted tobacco stems respectively; the extraction solution is disposed of separately, the tobacco stems are squeezed dry, and shredded to obtain shredded stems, which are to be evaluated after being dried.

[0036] The processes such as pressing stems, squeezing, and drying refer to existing conventional technologies.

[0037] The gap between the rolls of the stalk is set at 0.7-1.0mm, HDT expansion technology is adopted, and the temperature is set at 200°C-220°C.

Embodiment 3

[0039] S1. Clean the tobacco stems;

[0040] S2. Using 80°C hot water 8mL to extract 1g of tobacco stems for 60min;

[0041] S3. After leaching, filter to collect the extraction solution and the extracted tobacco stems respectively; dispose of the extraction solution separately, squeeze the tobacco stems dry, cut into shreds to obtain shredded stems, and dry the shredded stems for use in the cigarette leaf group in the recipe.

[0042] The processes such as pressing stems, squeezing, and drying refer to existing conventional technologies.

[0043] The gap between the rolls of the stalk is set at 0.7-1.0mm, HDT expansion technology is adopted, and the temperature is set at 200°C-220°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com