Wave gear device having tapered flexible external gear

A wave gear device, flexible technology, applied in the direction of gear transmission, transmission, components with teeth, etc., can solve the problem of insufficient consideration, and achieve the effect of increasing the transmission load torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Next, a wave gear device to which the present invention is applied will be described with reference to the drawings.

[0043] (Structure of wave gear unit)

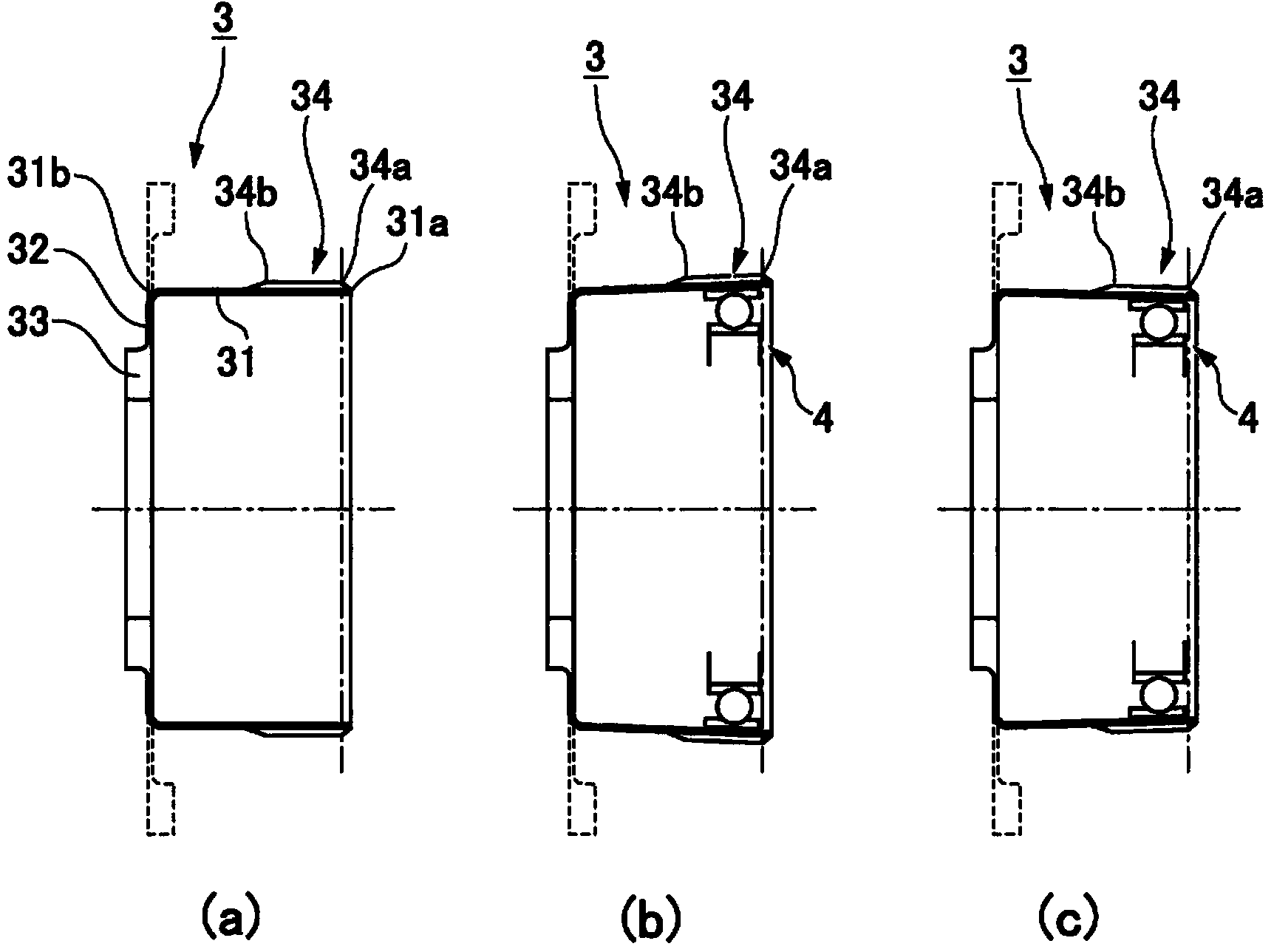

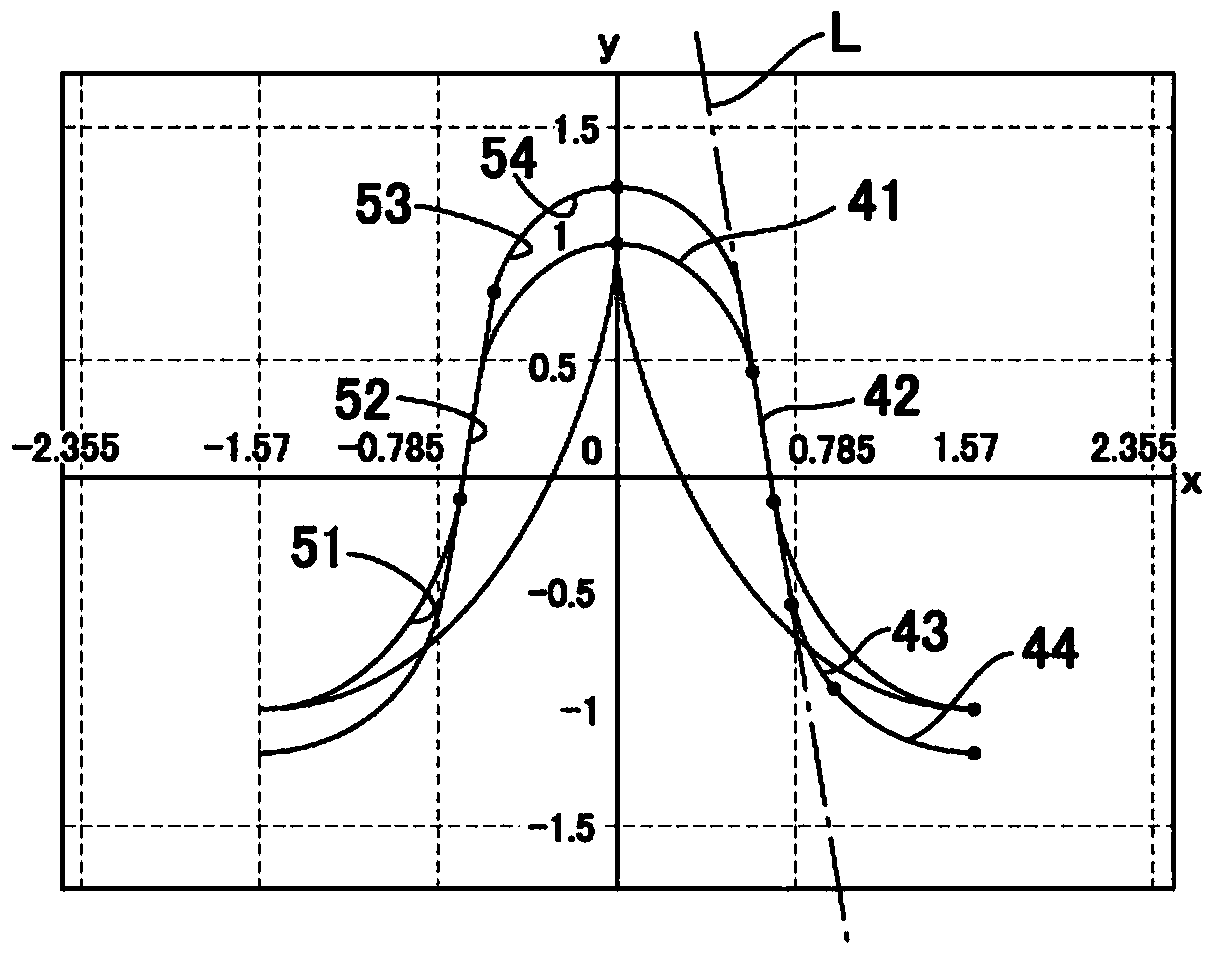

[0044] figure 1 It is a front view of the wave gear device which is the object of the present invention. figure 2 This is a cross-sectional view showing the state of bending the opening of the flexible external gear into an elliptical shape, including the shaft section, figure 2 (a) shows the state before deformation, figure 2 (b) shows the deformed section containing the major axis of the elliptic curve, figure 2 (c) shows a deformed section containing the minor axis of the elliptic curve. in addition, figure 2 In (a) to (c), the solid line shows a cup-shaped flexible external gear, and the dotted line shows a top-hat-shaped flexible external gear.

[0045] As shown in these figures, the wave gear device 1 has an annular rigid internal gear 2, a flexible external gear 3 arranged inside it, and a wave ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com