Rotating multi-channel power transmission device

A multi-channel power transmission device, brush technology, applied in the direction of rotating current collectors, circuits, current collectors, etc., can solve the problems of circuit disconnection, large size, loose contact between brushes and conductive rods, etc., to ensure contact reliability. , to ensure the effect of conduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

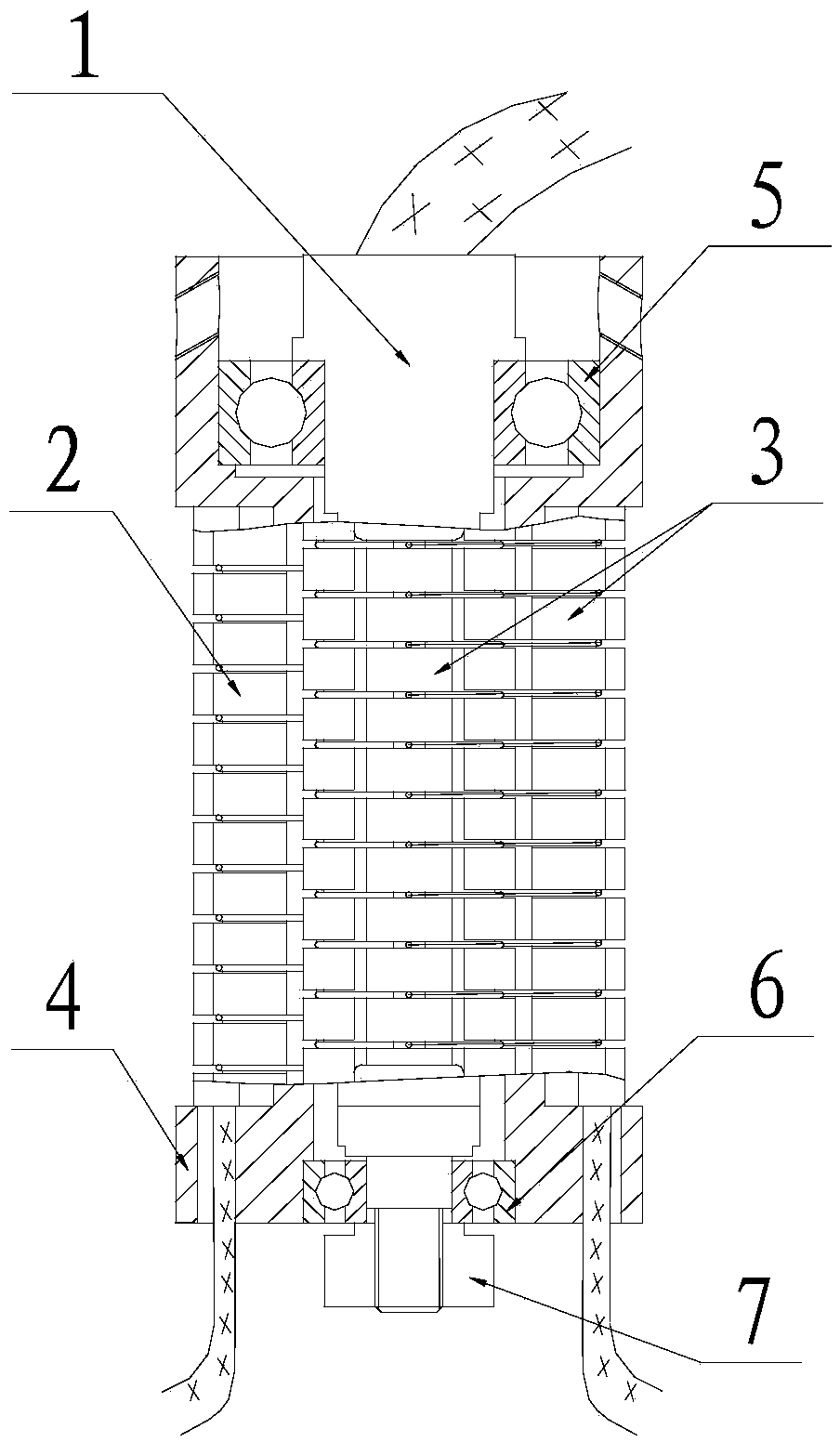

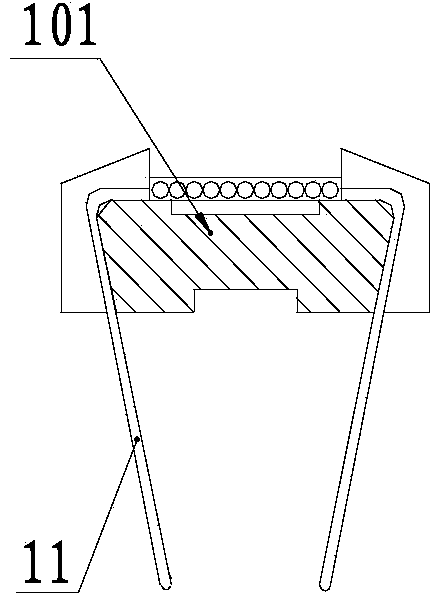

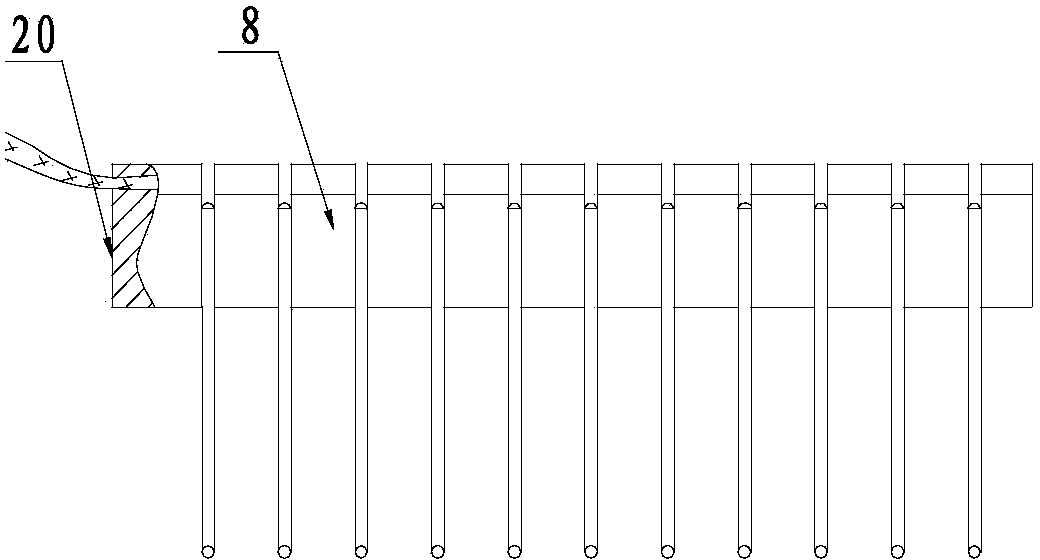

[0020] Such as figure 1 As shown, the high-reliability miniature rotary multiple power transmission device of the present invention includes a conductive rod 1, a first brush part 2, a second brush part 3, and a bracket 4. The conductive rod 1 is installed inside the bracket 4, and the conductive rod 1 It can rotate relatively freely with the bracket 4; the first brush part 2 and the second brush part 3 are fixed on the bracket 4; the structure and composition of the first brush part 2 and the second brush part 3 are the same. The first brush part 2 and the second brush part 3 are both composed of a U-shaped brush assembly 8 and an L-shaped brush assembly 9, so that the first brush part 2 and the second brush part 3 have multiple layers The brushes are insulated from each other; the U-shaped brush assembly 8 and the L-shaped brush assembly 9 are both fixedly connected to the bracket 4 by means of cementing. The brushes of the first brush member 2 and the second brush member 3 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com