Detachable high-voltage connection structure and high-voltage connector

A high-voltage connector, detachable technology, applied in the direction of connection, connecting device parts, electrical components, etc., can solve the problems of unrepairable products, difficult slotting, time-consuming and labor-intensive, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

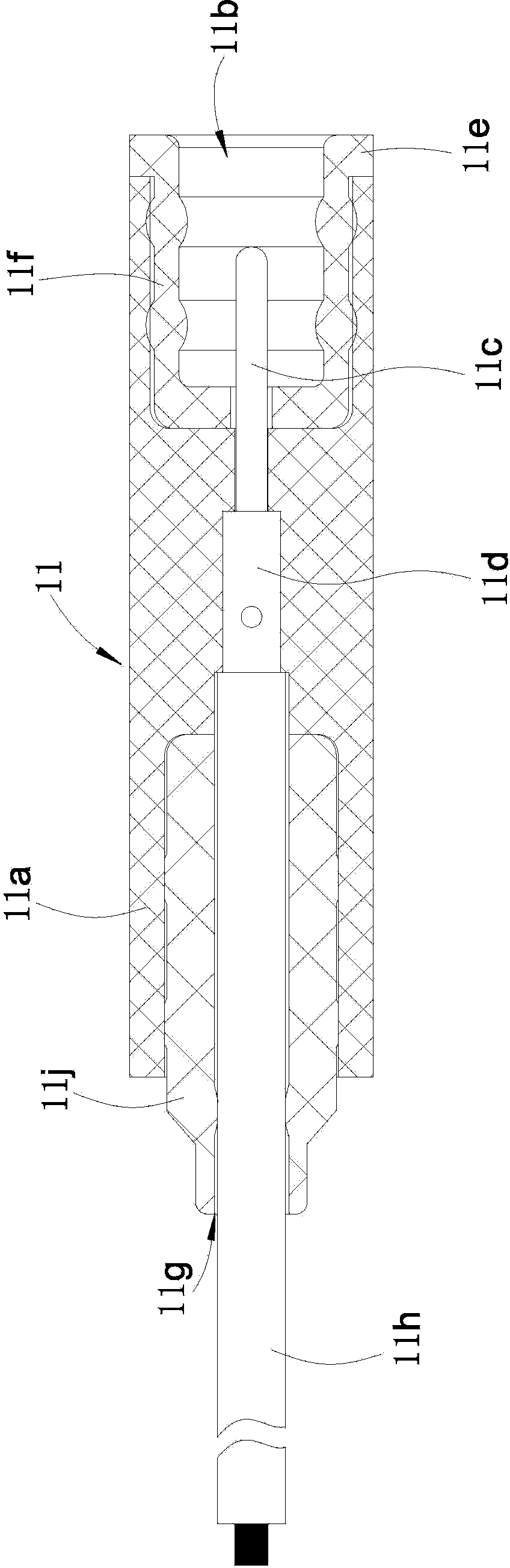

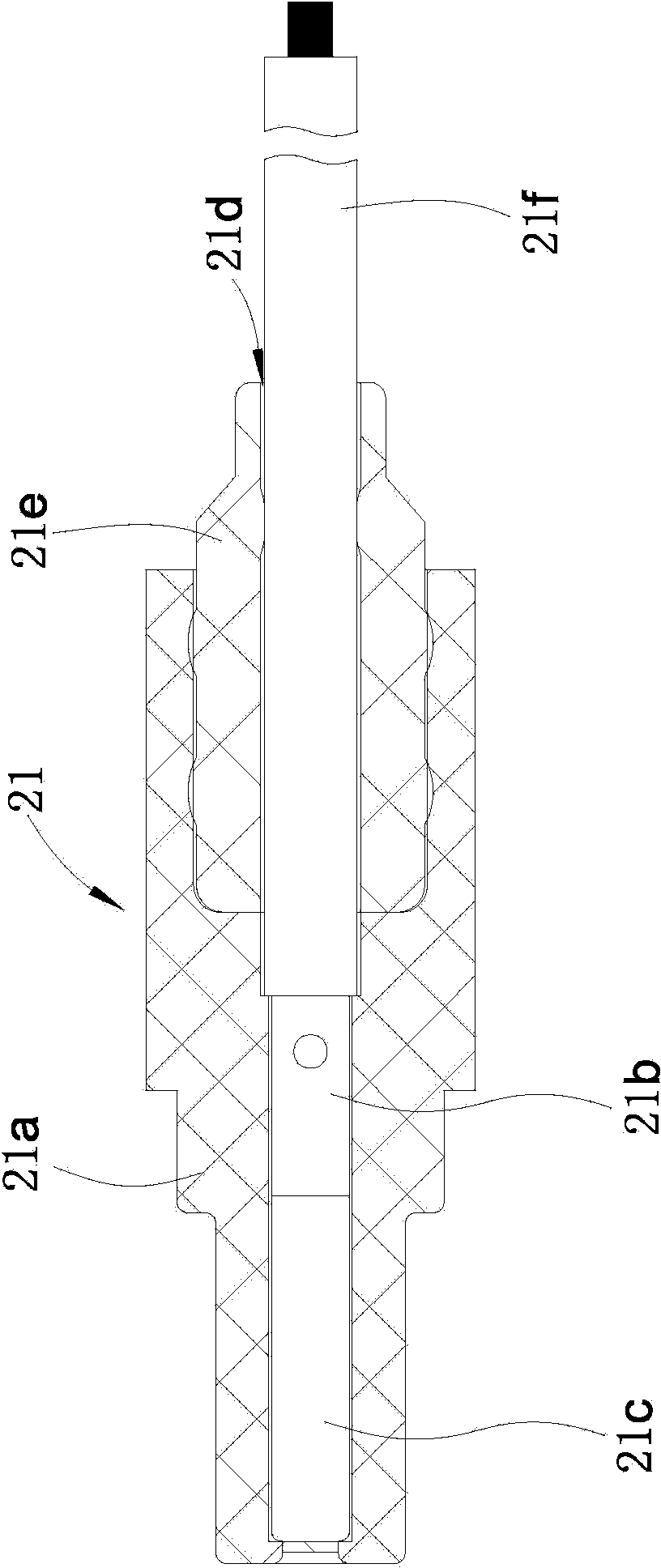

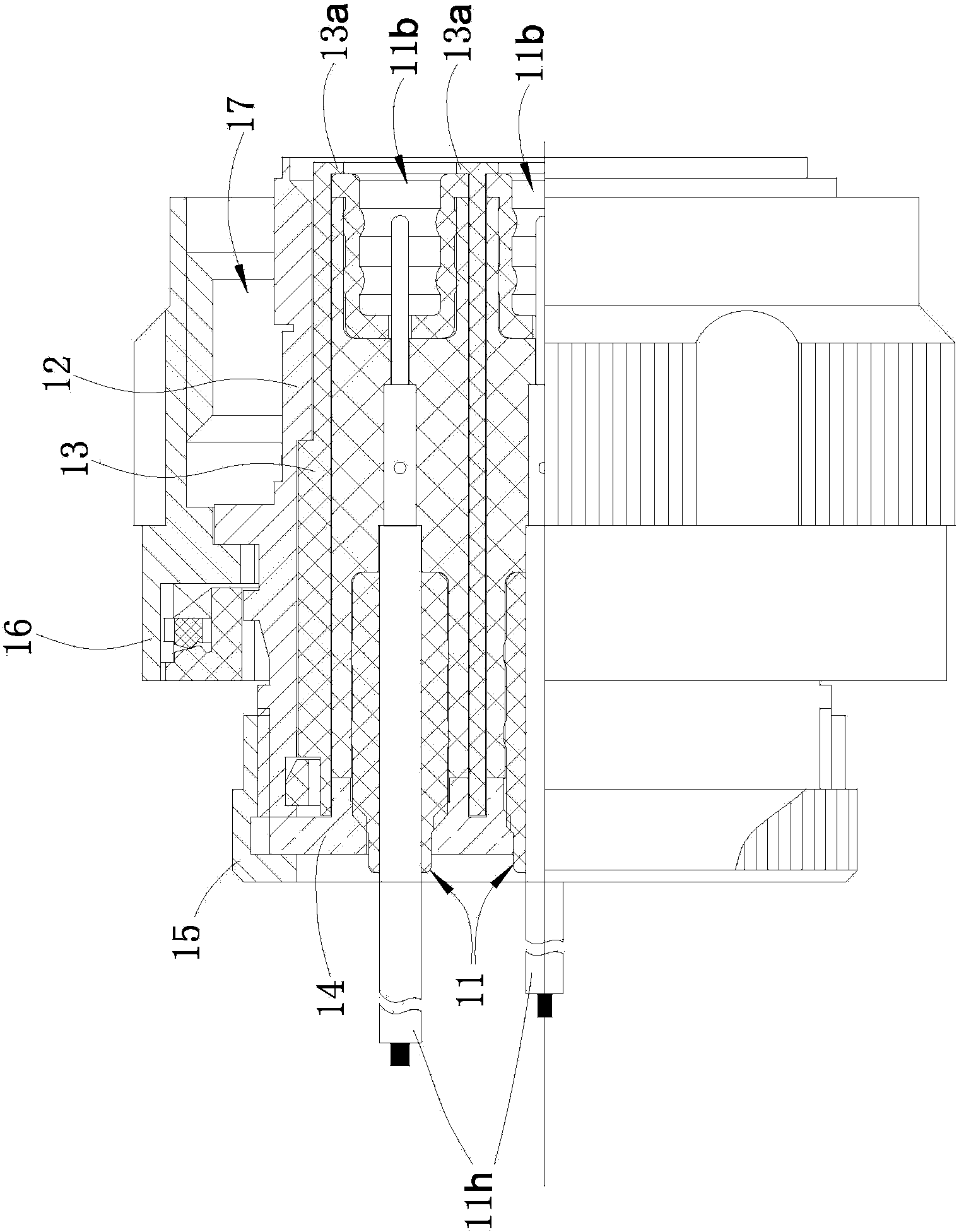

[0022] Such as Figures 1 to 2 as shown,

[0023] This structure includes jack assembly 21 and pin assembly 11;

[0024] The pin assembly 11 includes a pin housing 11a, a pin 11c, a first tail sleeve 11j and a sealing sleeve 11f. The material used for the pin housing 11a is insulating hard engineering plastic, and the front end of the pin housing 11a is provided with a concave Slot 11b, the middle part of the pin housing 11a has a mounting groove matching the shape of the pin 11c, so that the pin 11c is horizontally installed in the mounting groove, the rear part of the pin 11c is the first connecting end 11d, and the front end of the pin 11c extends into the concave In the groove 11b, an elastic insulating sealing sleeve 11f is set inside the groove 11b. The material of the sealing sleeve 11f is silicon rubber. The rear end of the pin 11c is closed and set on the pin 11c. The length of the pin 11c is such that its front end is located in the middle section of the sealing sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com