Novel fire-resistant cable

A fire-resistant cable, a new type of technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of rising production costs, increased outer diameter, and increased raw material consumption, so as to improve production efficiency, increase temperature resistance, and reduce production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

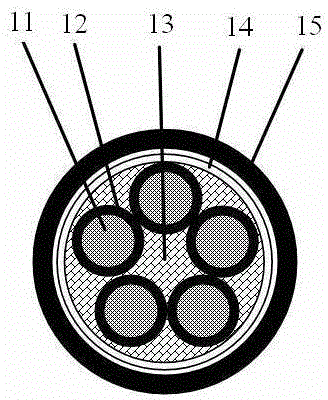

Embodiment 1

[0067] A ceramic fire-resistant cable with a rated voltage of 0.6 / 1 kV and below. The structure of the ceramic fire-resistant cable is basically the same as that of the non-fire-resistant product of this type. The cable wrapping tape is replaced with a 2-layer ceramic fire-resistant and fire-resistant composite tape. . The ceramic refractory cable includes five insulated wire cores, and each insulated wire core includes a copper conductor 11 and a cross-linked polyethylene insulating layer 12 covering the copper conductor 11 . The 5 insulated wire cores are wrapped with 2 layers of ceramicized fireproof and refractory composite tapes 14, and there are polypropylene mesh belt filling layers 13 between the insulated wire cores and between the insulated wire cores and the porcelainized fireproof and refractory composite tapes 14. Porcelain fireproof and refractory composite belt 14 is extruded with PVC outer sheath 15, see figure 1 .

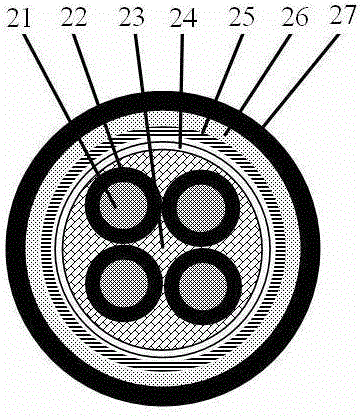

Embodiment 2

[0069] A new type of fire-resistant cable, including four insulated wire cores, each insulated wire core includes a copper conductor 21 and a polyvinyl chloride insulating layer 22 covering the copper conductor 21. The 4 insulated wire cores are wrapped with 2 layers of ceramicized fireproof and refractory composite tapes 24, and there are polypropylene mesh belt filling layers 23 between the insulated wire cores and between the insulated wire cores and the porcelainized fireproof and refractory composite tapes 24. Porcelain fire-proof and refractory composite tape 24 is extruded with PVC inner sheath 25, and the outer side of PVC inner sheath 25 is provided with galvanized steel tape armor layer 26, and the outer side of armor layer 26 is extruded with PVC outer sheath 27 ,See figure 2 .

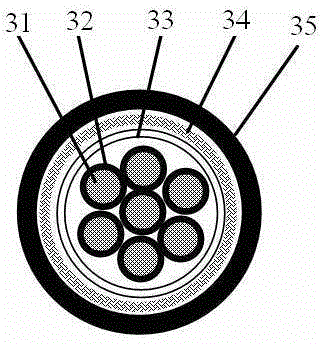

Embodiment 3

[0071] A new type of fire-resistant cable, including 7 insulated wire cores, each insulated wire core includes a copper conductor 31 and a cross-linked polyethylene insulating layer 32 covering the copper conductor 31. The 7 insulated wire cores are wrapped with 2 layers of ceramicized fireproof and refractory composite tape 33, and a copper wire braided shielding layer 34 is arranged on the outer side of the porcelainized fireproof and refractory composite tape 33, and the outer side of the shielding layer 34 is wrapped with a halogen-free flame-retardant low-smoke polyolefin outer layer. Sheath 35, see image 3 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com