Dimension analysis-based metal mine goaf overlaying strata caving height prediction method

A technology of dimensional analysis and prediction method, applied in special data processing applications, instruments, electrical digital data processing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

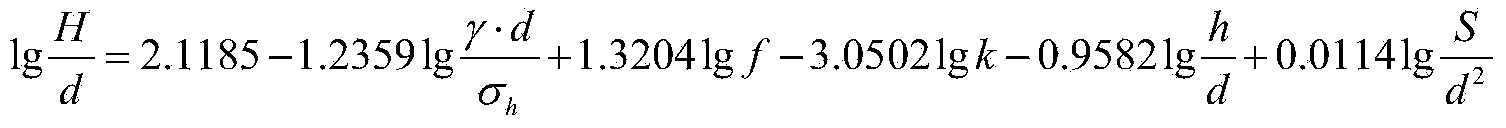

Method used

Image

Examples

example 1

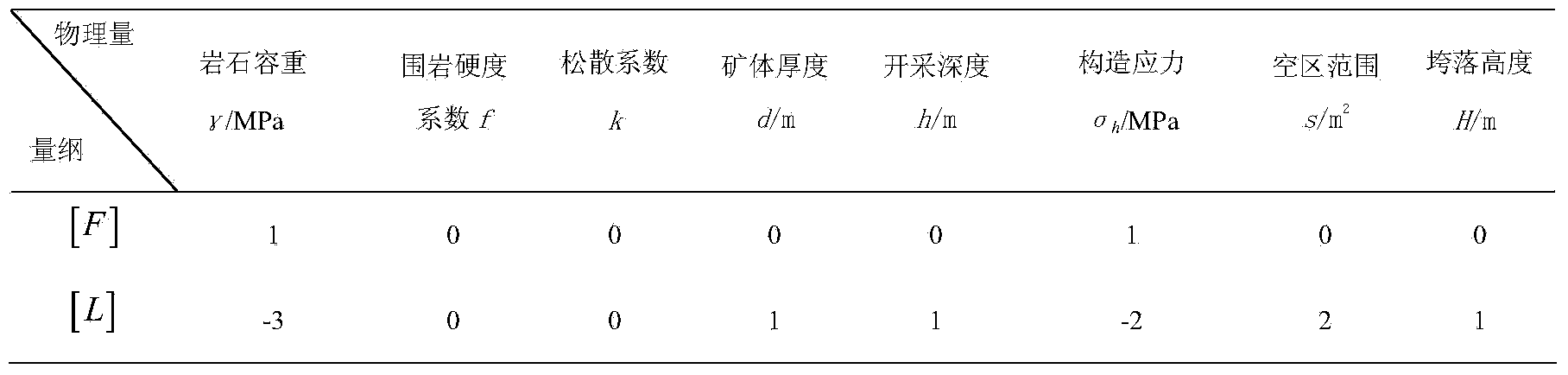

[0048] The Jiaochong Gold Mine is located in Tongling County, Anhui Province. The ore body strikes 55°, dips southeast, with a dip angle of 10°-30°, vein thickness of 5-8m, with an average of 6m, and an average surface elevation of 160m. Mainly rock and marble, f=14~16. When the 05 stope is mined in the middle section of -460m, the roof span of the goaf is as high as 6.2m, and the area of the goaf is about 400m 2, the specific relevant physical parameters are shown in Table 4.

example 2

[0050] The Rushan Gold Mine is located in Muping, Jiaodong. The mining depth of the mine is 505m, the thickness of the ore body is 0.27-7.4m, and the average thickness is 2.73m. The surrounding rocks of the roof and floor of the orebody have been altered, f=13-15. When the 02 stope was mined in the middle section of -385m, the surrounding rock of the ore body appeared to sink and caving with a thickness of 5-6m, and the roof of the ore body collapsed with an area of 10m 2 , the goaf area is 64,000 m 2 , the specific relevant physical parameters are shown in Table 4.

example 3

[0052] Hongtoushan Copper Mine is located in Hongtoushan Town, Qingyuan Manchu Autonomous County, Fushun City, Liaoning Province. The average thickness of the ore body is between 2.3 and 3m. The ore and surrounding rock are moderately stable. The mining depth is 770m from the surface. The surrounding rocks of the upper and lower walls are gneiss, f=12~14. Due to the large ground pressure in the deep part, the possibility of large-scale collapse in mining is very high. According to the mine's statistics on the caving area, the stope area of 11# mining area is 618m 2 , of which the area of the larger one collapsed was 50-70m 2 , the specific relevant physical parameters are shown in Table 4.

[0053] Table 4 Comparison of predicted and measured values of overlying rock caving height in metal mines*

[0054]

[0055] ( * ④The measured caving height of Jiaochong Gold Mine in the table is 6.2m measured by HILTI PD40 laser range finder; The collapse area is 50~70m 2 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com