Colored-film substrate, manufacturing method of colored-film substrate and display device

A technology of color film substrate and manufacturing method, which is applied in nonlinear optics, instruments, optics, etc., and can solve problems such as increased power consumption of TFT-LCD

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

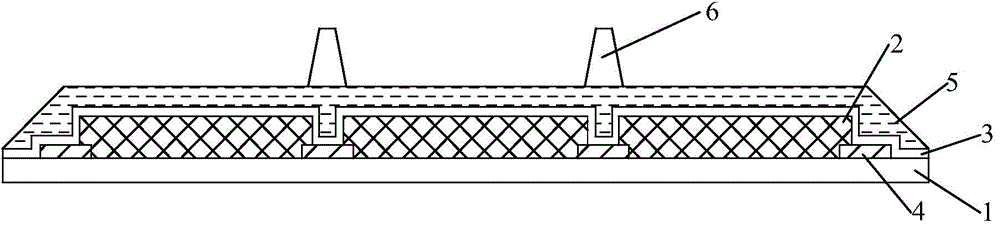

[0034] An embodiment of the present invention provides a color filter substrate, such as figure 1 As shown, the color filter substrate includes a base substrate 1 and a color filter layer 2 located on the base substrate 1, and also includes:

[0035] The quantum dot layer 3 located on the color filter layer 2, the quantum dot layer 3 includes at least three kinds of quantum dots, and any quantum dot in the quantum dot layer 3 is excited by light to emit light of the corresponding wavelength band .

[0036] Quantum dots are extremely tiny semiconductor nanocrystals that cannot be seen by the naked eye. They are composed of zinc, cadmium, selenium, and sulfur atoms. The diameter of the particles in the crystal is usually less than 10 nanometers. It has a distinctive feature: it will emit light when stimulated by electricity or light, and produce pure color light. Specifically, the color of the emitted light is determined by the composition material, size and shape of quantum do...

Embodiment 2

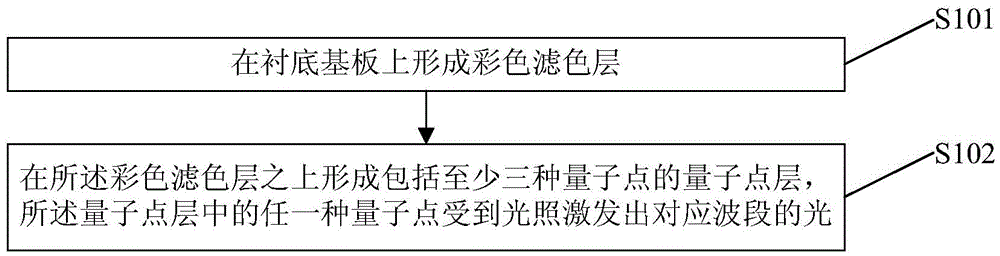

[0055] The embodiment of the present invention provides a method for manufacturing the color filter substrate described in Embodiment 1, as shown in figure 2 As shown, the production method includes:

[0056] Step S101 , forming a color filter layer on a base substrate.

[0057] Step S102 , forming a quantum dot layer including at least three kinds of quantum dots on the color filter layer, and any type of quantum dot in the quantum dot layer is excited by light to emit light of a corresponding wavelength band.

[0058] Wherein, the thickness of the quantum dot layer 3 is 0.01-2 μm.

[0059] Usually, before forming the color filter layer 2, it also includes forming a black matrix 4 on the base substrate 1, and step S101 includes forming a color filter layer on the black matrix.

[0060] Further, the production method also includes:

[0061] A planarization layer and spacers are formed over the quantum dot layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com