Holographic shading laser packaging material print quality inspection system and inspection method

A quality inspection method and packaging material technology, applied in the direction of analyzing materials, material analysis by optical means, measuring devices, etc., can solve the problems of automatic completion of equipment, difficulty in quality inspection, and lack of a more effective inspection method, etc. Solve detection problems, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

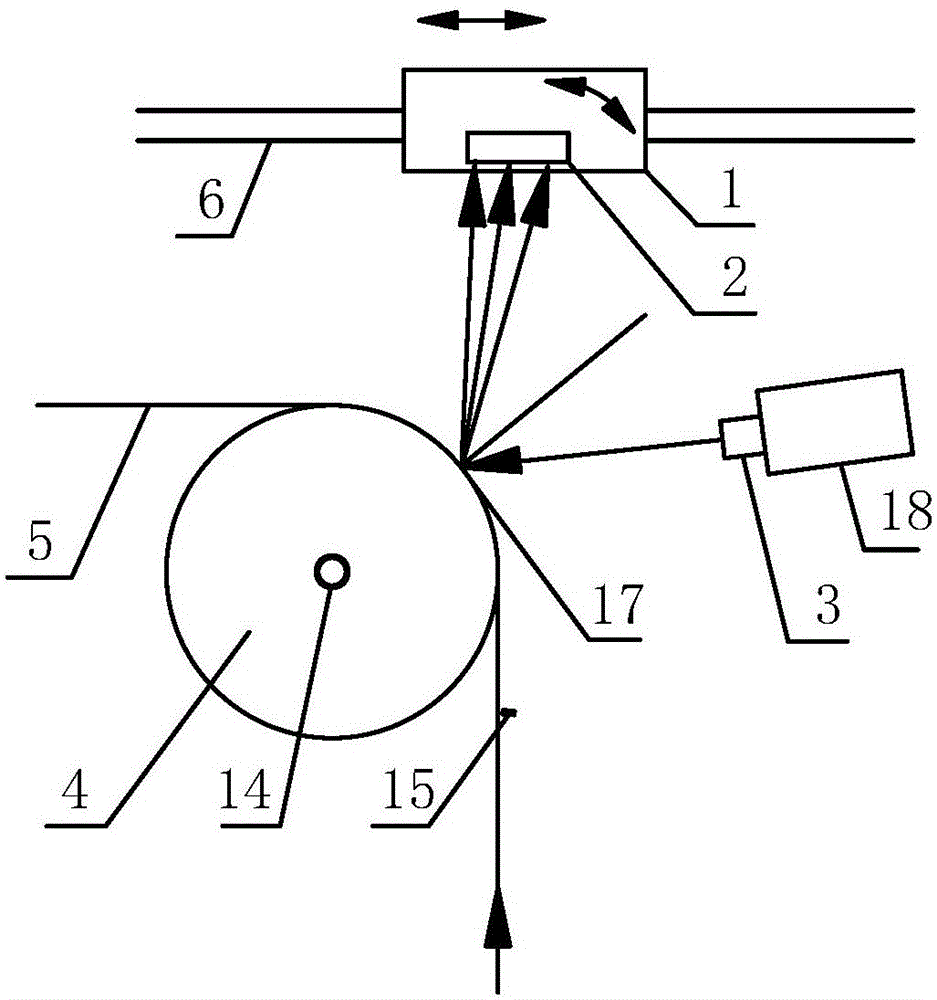

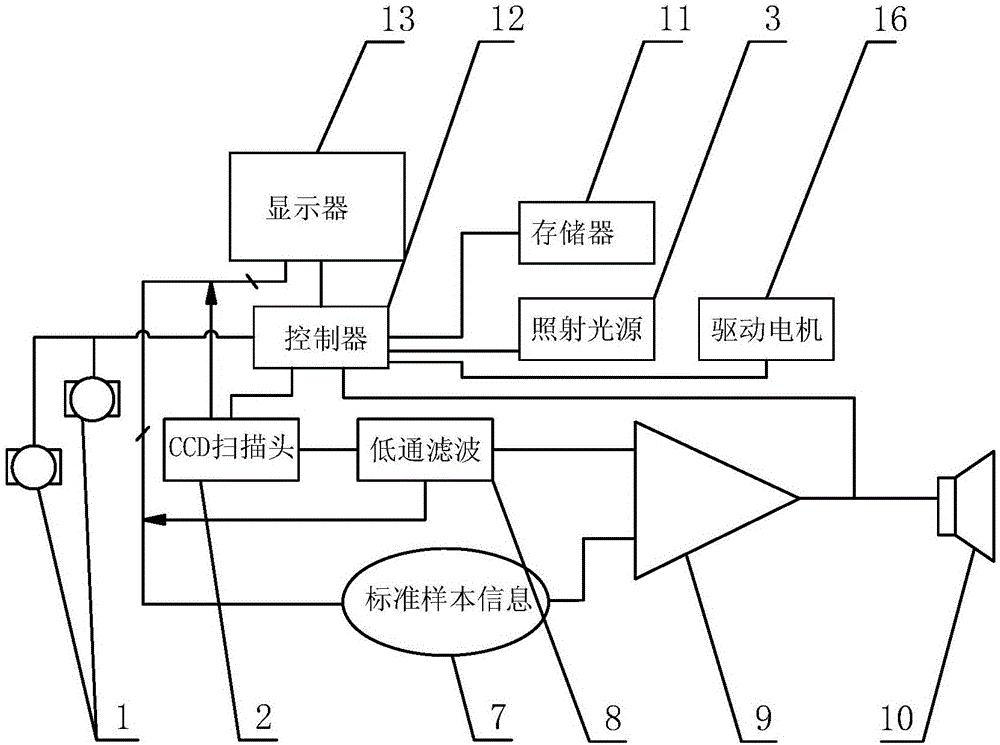

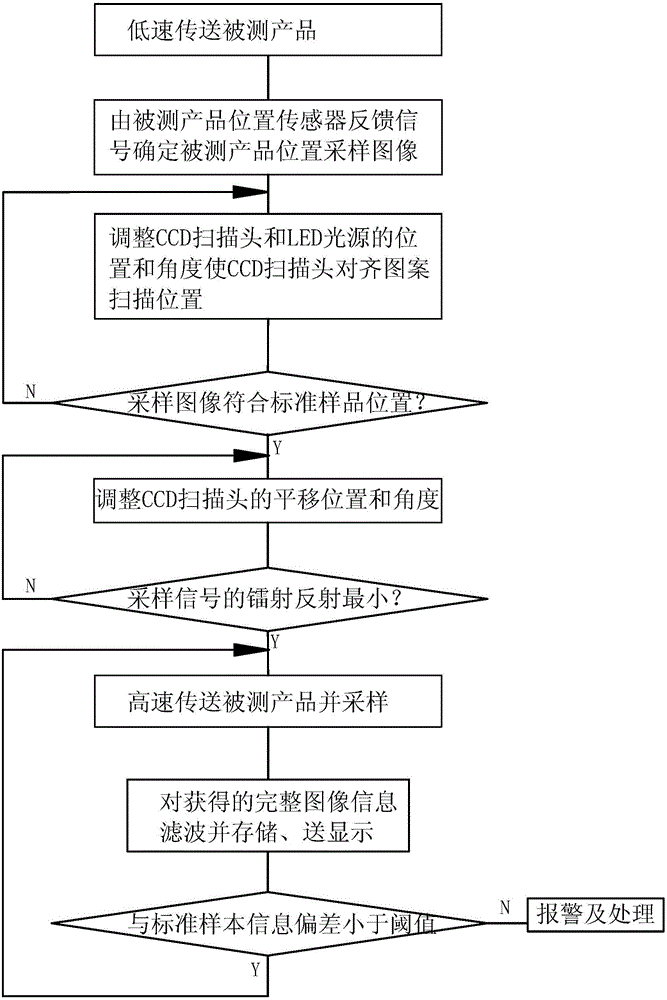

[0031] Below in conjunction with accompanying drawing and embodiment the present invention is further described: as figure 1 , 2 As shown in , the holographic shading laser packaging material printed product quality inspection system is used for the apparent quality inspection of the laser shading printed matter in an unfixed position, on the outside of a transfer roller 4 that supports the holographic laser shading printed sheet An LED light source 3 and a CCD scanning head 2 are provided, and the CCD scanning head 2 is installed on the laser-avoiding drive mechanism 1, and the LED light source 3 and the CCD scanning head 2 are asymmetrically arranged on both sides of the normal line of the detection point 17, The laser-avoiding drive mechanism 1 can at least move linearly and rotate around the central axis in a plane passing through the detection point 17 and perpendicular to the axis of the transfer roller 4, and is used to adjust the CCD scanning head 2 so that the CCD sca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com