Wireless measurement method of hinge torque on dynamic balance test bench

A hinge torque, wireless measurement technology, applied in the field of helicopter testing, can solve problems such as inaccurate data of hinge torque measurement system, and achieve the effect of shortening maintenance cycle, reducing maintenance cost, and strong anti-interference ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] (1) System connection

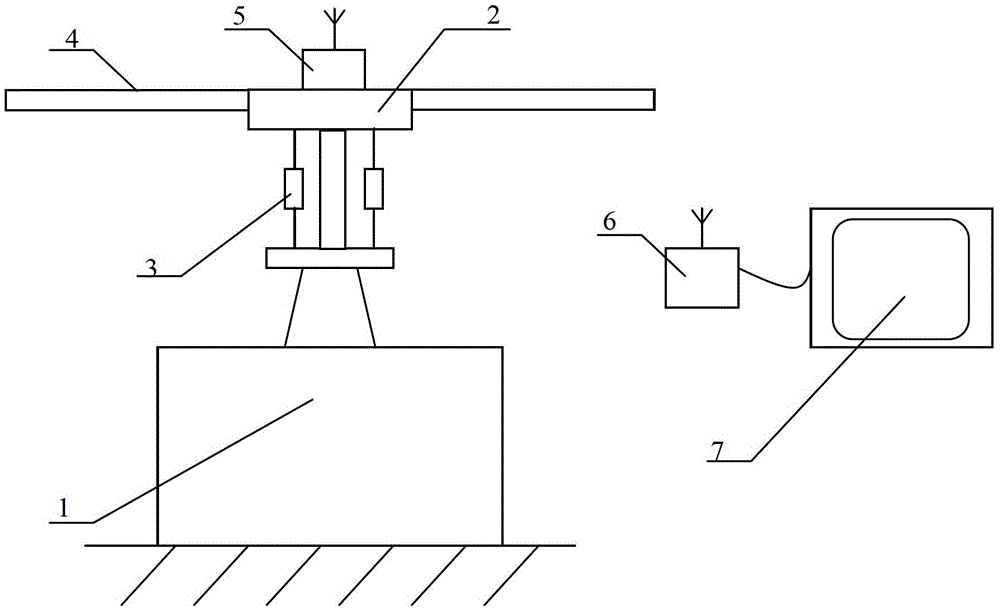

[0018] The rotor head 2 is installed on the rotor blade dynamic balance test bench body 1, the helicopter blade 4 is installed on the rotor head 2, the force sensor 3 is installed on the rotor head 2, and the launching device 5 is installed at the center of the upper end of the rotor head 2. The force sensor 2 is connected to the transmitter 5 through a wire. The receiving device 6 is connected to the signal acquisition device 7 through a wire.

[0019] (2) System operation process

[0020] The first step is to turn on the power and turn on the wireless measurement system.

[0021] In the second step, the dynamic balance test bench is started, and the rotor head drives the helicopter blades to rotate to generate signals.

[0022] The third step is to analyze and record the signals received through the wireless device to complete the measurement.

[0023] The fourth step is to turn off the power.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com