Solar energy cooker system

A solar cooker and solar collector technology, which is applied to solar heating systems, solar thermal energy, solar thermal power generation, etc., can solve the problems of difficulty in troubleshooting, increase water storage, and consume thermal energy, saving production materials and reducing operation. cost, the effect of improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in further detail below in conjunction with the accompanying drawings: the present embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation is provided, but the protection scope of the present invention is not limited to the following embodiments.

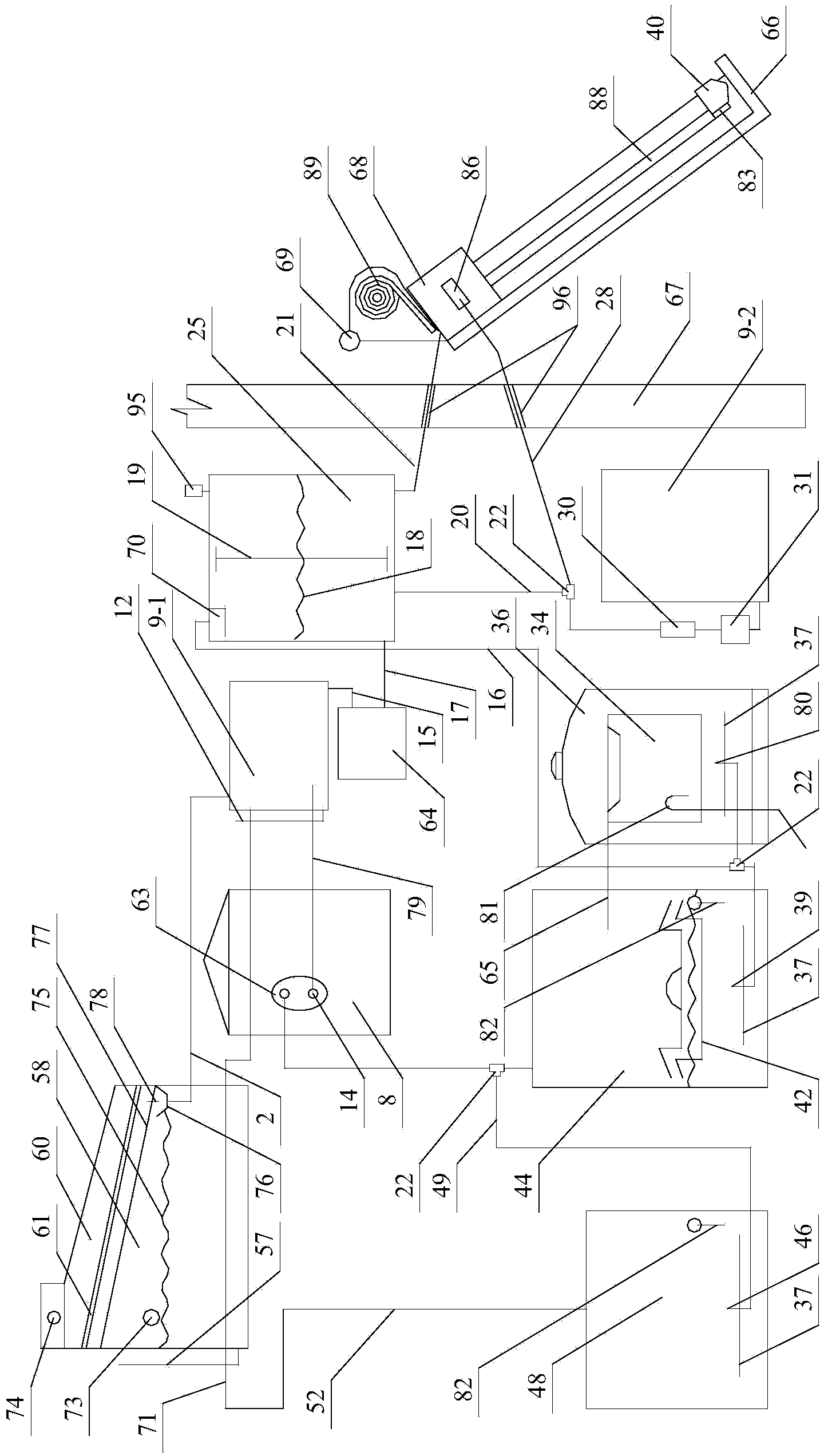

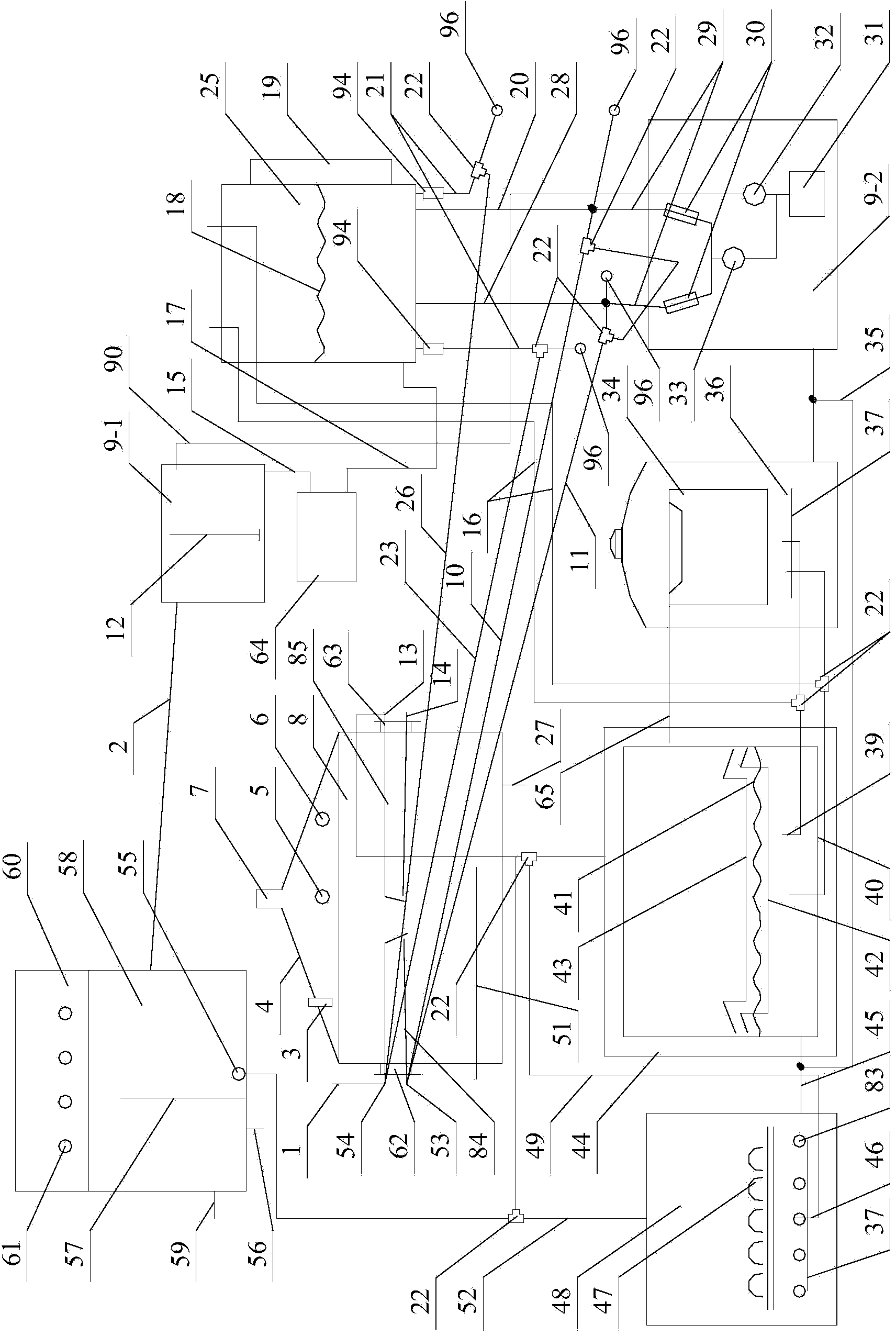

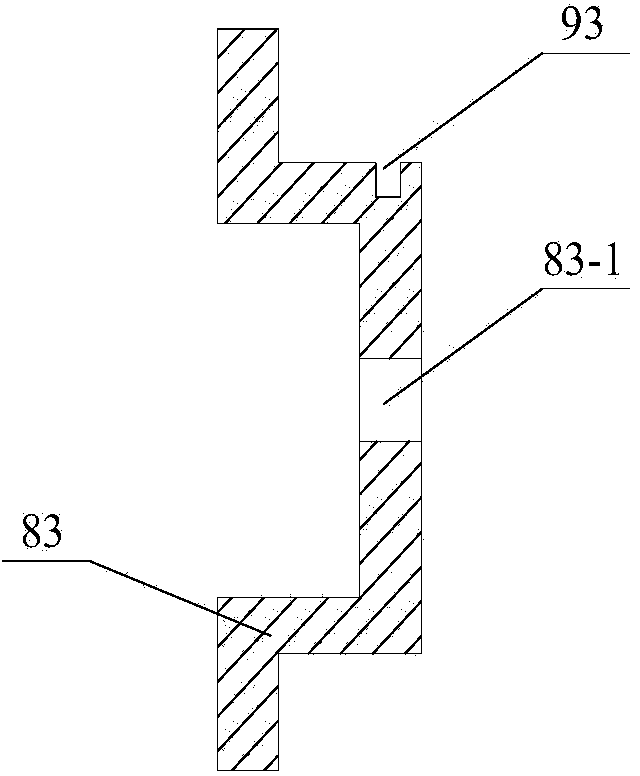

[0016] Such as Figure 1 to Figure 6As shown, a solar cooker system involved in this embodiment includes: a first pipeline 2, a hot water tank 8, a high water tank 9-1, a low water tank 9-2, a second pipeline 10, a third pipeline 11, a water level Sight pipe 12, fifth pipe 15, steam pipe 16, seventh pipe 17, water level display glass pipe 19, first return water pipe 20, upper water and steam pipe 21, fourth pipe 23, steam-water separator 25, eighth pipe 26. The second return pipe 28, the electric heater 30, the water pump 31, the first valve 32, the second valve 33, the ninth pipeline 35, the cooking barrel 36, the electri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com