Precast concrete wall body

A prefabricated concrete and wall technology, applied to walls, building components, buildings, etc., can solve the problems of poor integrity and achieve the effects of convenient transportation, high level of industrialization, and improvement of industrialization level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The prefabricated concrete wall of the present invention will be described in detail below with reference to the accompanying drawings and embodiments.

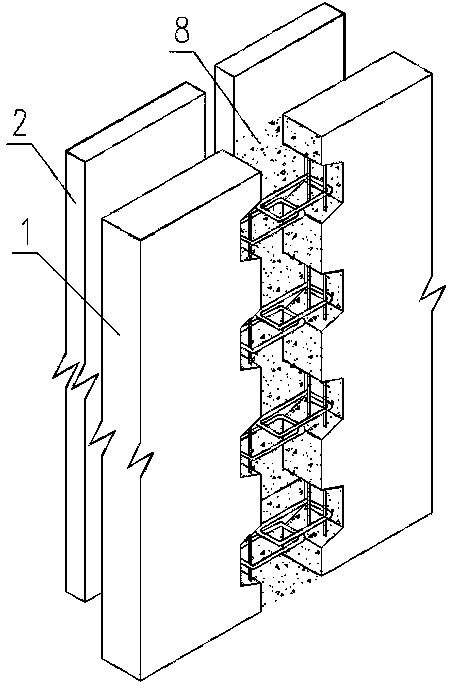

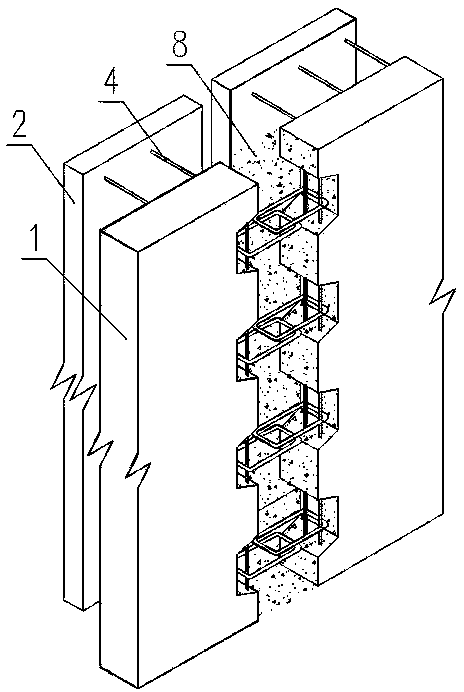

[0031] An embodiment of the prefabricated concrete wall proposed by the present invention, such as figure 1 , the precast concrete wall includes a first precast concrete wall panel 1 and a second precast concrete wall panel 2 arranged in parallel, the first precast concrete wall panel 1 adopts wet connection, that is, the first precast concrete wall panel 1 The concrete 8 is connected together; the 2 second prefabricated concrete wall panels are dry-connected, through reserved anchor steel plates or other steel components, and bolted or welded ( figure 1 not shown).

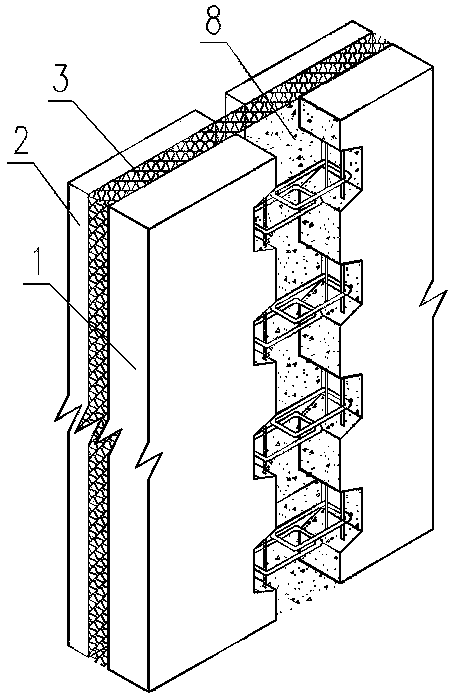

[0032] Another embodiment of the prefabricated concrete wall proposed by the present invention, such as figure 2 , The insulation layer 3 is set between the first precast concrete wall panel 1 and the second precast concrete wall panel 2 . Or a waterp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com